Custom Forging Service for Gear Manufacturing

Backed by advanced forging and CNC technology, HDC offers one-stop solutions for custom-built gears. From forged gear blanks to precision finished gears, we forge them exactly for your project

Gears We Manufacture

With comprehensive manufacturing capabilities, we support your unique design with precision and reliability.

Gear Blanks

If you have manufacturing capabilities to cut teeth and finish the gear, or need to specify a machining manufacturer, HDC can provide mass gear blanks at a competitive price.

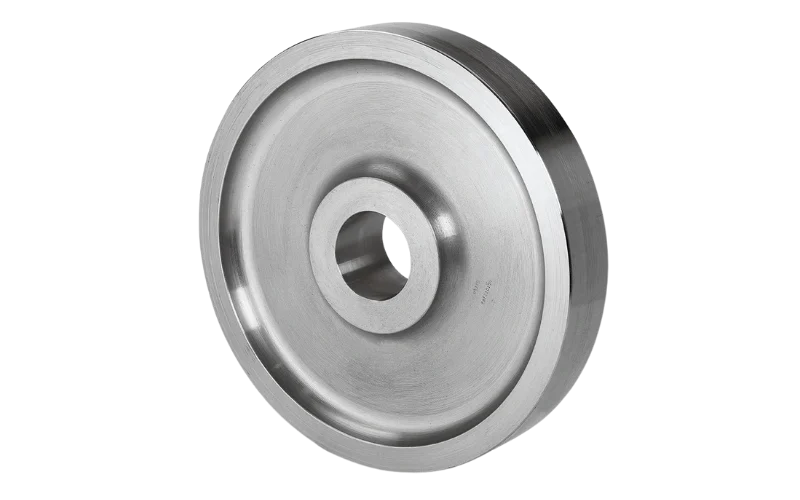

Cylindrical Gears

Cylindrical is the most common gear shape. HDC can fabricate it with a spur tooth or a helical tooth for various of industrial applications, such as the transmission box in a car.

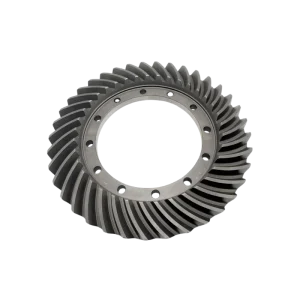

Bevel Gears

Bevel gear is widely used in the differential and steering mechanisms. By forging, we enable near-net shape forming, resulting in better production efficiency and tooth root strength.

Face Gears

For engineers who are chasing a compact layout and high load capacity, a face gear is definitely the right answer. By forging, we further enhance its properties in high-end applications.

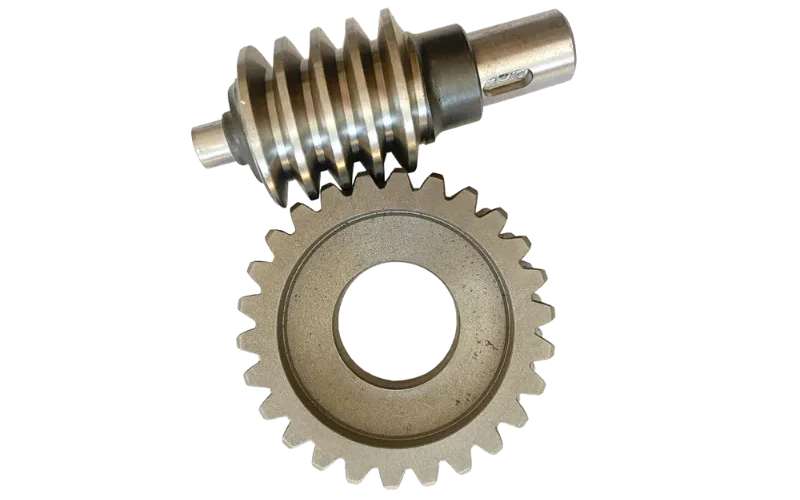

Worm Gears

HDC primarily supplies unprocessed worm gear blanks. If you require, we can also finish it according to your design.

Benefits of Forged Gears

Why forge gears instead of casting and machining? Here are the answers.

Better Gear Tooth Strength

Through close-die forging, you can get a stronger tooth root structure created by controlled grain flow.

Longer Serving Life

Forging produces a dense, uniform microstructure, helping your gears last longer under repeated cyclic loads.

Minimal Waste & Cost Effective

Close-die forging produces gear blanks very close to the final shape, which requires less machining and leads to cost-effectiveness.

High Consistency

Forging with a precision-machined die, we produce gear blanks with consistent and predictable quality.

HDC Core Capabilities

HDC controls all the manufacturing processes for stable and consistent quality.

Forging

We utilize close-die forging to produce gear blanks with optimized strength, setting a solid foundation for the gear you require.

Heat Treatment

We apply heat treatment in-house, ensuring that every batch of gears reaches the mechanical properties in your design.

Machining

Combined with CNC machining, we finish your gear with accurate geometry and tolerances, ensuring it is ready for real applications.

Quality Control

We utilize CMM, gear profile testers, and hardness testers to ensure every gear meets ISO/DIN standards before shipping.

For a full overview, please visit our Forging and CNC Machining Capability pages.

Materials for Forged Gears

We work with a wide range of materials for your custom forged gear project.

For gear used in agricultural machinery and general industrial equipment that has moderate performance requirements, we recommend carbon steel due to its excellent formability and lower cost. Carbon steel grades we offer include: 1045, C45, etc.

Surface & Heat Treatments Options

For customers who need finished gears that are ready to use, we offer comprehensive surface and heat treatment options for you to choose from. Which including:

- Quenching & Tempering

- Hardening

- Bead Blasting

- Coating

- Polishing

We apply surface & heat treatments based on your requirements and the metal used to achieve desired results.

Technical Specifications

Get a detail look about our capabilities in forging gears through this comprehensive table.

| Gear Type | Cylindrical (Straight/Helical), Bevel, Face, Internal |

| Material | Alloy Steel (20CrMnTi, 42CrMo), Carbon Steel, Stainless Steel |

| Module (m) | 1 – 12 mm (customizable) |

| Number of Teeth | 8 – 200+ (depending on gear type) |

| Pitch Diameter | 20 – 500 mm |

| Hardness | HRC 45–60 (after heat treatment) |

| Surface Finish | Ra 0.8 – 1.6 μm (after grinding/polishing) |

| Tolerance / Accuracy | ISO 6 – ISO 8 (optional higher precision) |

| Maximum Gear Weight | Up to 30 kg per piece (customizable) |

Custom Forged Gears - Build for Your Project

Send us your drawings or requirements, and we’ll provide a detailed quote with lead time and material recommendations—fast, reliable, and tailored to your application.

FAQ

Why should I choose forged gears over fully machined ones?

In short, forging is a mature process for the mass production of gears. Usually, it needs to be combined with CNC machining, that is, forging for the blank and CNC finishing the details.

Full CNC-machined gears are not practical in real applications; in most situations, it’s used for prototype and functional validation.

Do you provide finished gears or just blanks?

Both. We supply forged gear blanks for customers with their own machining, and fully finished gears with CNC precision, heat treatment, and surface treatment as needed.

Do you provide heat treatment reports and material certifications?

Yes, heat treatment reports and material certifications are available upon request.

Can you reverse engineer from a sample?

Of course, send us the sample, we will scan it, create the CAD drawing, and manufacture a perfect replacement.

What is the typical lead time for a custom gear order?

Lead time depends on gear type, size, and quantity. Small to medium batches typically ship within 3–6 weeks. We provide detailed lead time estimates with each quote.

Can HDC support international shipments?

Absolutely. We export forged gears globally, including Europe, North America, and Asia. Logistics and packaging are handled professionally to ensure safe delivery.