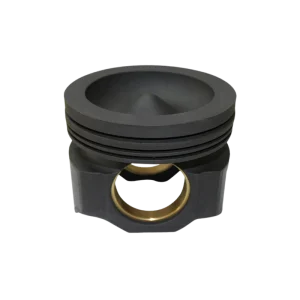

Custom Forged Pistons for High-Performance Engines

Precision-forged and CNC-machined pistons tailored for automotive, motorcycle, karting, and small-engine manufacturers.

Forged Pistons by Applications

HDC customizes forged pistons for a wide range of engines. You can always find a solution here.

Automotive Pistons

HDC forges pistons with wear-resistant aluminum and precision CNC machining for the details. Whether it’s for an SUV or a truck, for a diesel engine or a gasoline engine, we can custom fabricate for you.

Motorcycle Pistons

To cope with the high rpm and heat of motorcycle engines, we employ 2618 and 4032 aluminum to forged pistons for performance engines, OEM replacements, and small-batch custom builds that require consistent quality.

ATV / UTV Pistons

Except for the heat and wear inside the engine, an ATV piston also needs to withstand intense impact, vibration, and high torque operation in off-road riding. HDC solves this by precision close-die forging and 5-axis CNC machining.

Kart Pistons

Despite its small size, kart engines have a harsher environment for their pistons than cars, as they must withstand higher rpm and limited heat dissipation. To achieve ultimate lightweight and reliability, we optimize the piston according to your engines.

Small Engine Pistons

Engines are everywhere: generators, mowers, pumps, and compact industrial engines. HDC not only focuses on pistons used in racing, but also lays our sights on daily tools. Let’s work together for a quiet and efficient user experience through specially designed pistons.

Scooter Engine Pistons

Extreme performance is not what a scooter engine piston aims for. Wear resistance, stable lifespan, and smoothness are more important. HDC works with 4032 forged aluminum and exact CNC processing of skirts, grooves, and crown shapes for reliable performance in city riding conditions.

Why Choose HDC

What are the benefits of sourcing customized pistons from HDC? Here is the answer.

High-Strength Forging

Superior fatigue resistance using 2618 / 4032 / high-strength forged aluminum. Built for the high-performance engine.

Tight CNC Tolerances

Machining accuracy up to ±0.01mm for optimized combustion efficiency. Backed by our in-house 4-axis machining center.

Custom Profiles & Designs

Dome, dish, flat-top, pocketing, oil-gallery cooling, weight reduction, etc, we bring your unique design to life.

Easy & Reliable Sourcing

Just specify your requirements, and we’ll handle the rest, with commitment to quality and on-time delivery.

How HDC Manufactures Forged Pistons

Learn more about HDC’s capabilities in forging heavy-duty hinges.

Forging the Piston Blank

We start by forging the aluminum billet into a dense, near-net-shape piston blank.

This step improves strength, removes porosity, and prepares the material for precision machining.

Heat Treatment & Stabilizing

Next, the forged blank goes through heat-treating processes. This enhances hardness, wear resistance, and keeps the piston stable under high temperature and RPM loads.

CNC Finishing Piston Gemotries

Finally, we machine all critical features: skirt profile, ring grooves, crown geometry, etc. With in-housing machining centers, we ensure tight tolerances and repeatability for OEM and racing applications.

Check out our quality control methods for forging parts.

Custom Piston Materials

Material is the foundation of a high-quality piston, and HDC always provides the best.

For vehicles that are chasing optimized performance, such as racing turbo cars and large-displacement motorcycles, forged aluminum pistons are the go-to choice. Cause aluminum has a balanced weight-to-strength ratio, easy to form with forging, and enhanced with heat treatment.

The common aluminum for pistons includes 4032, 2618, and 6061. In which 4032 is the most used material, suitable for mass production pistons that are used in durable engines. While 2618 has better strength, it is not as wear-resistant as 4032, so it is more used for high-performance pistons.

Steel pistons offer higher strength, higher hardness, and several times more impact resistance than aluminum pistons. But they are too heavy for most automotive gasoline engines. So the steel pistons are primarily used in high-pressure turbo diesel engines, heavy-duty trucks, construction machinery, and industrial engines.

The main steel grade that HDC forges for pistons is 4140(42CrMo4), which offers good machinability, high stability, and moderate cost.

Surface Treatments for Forged Pistons

HDC supplies forged piston blanks, and we can also deliver fully finished pistons through our trusted surface-treatment partners.

Hard anodizing is used on the crown and ring grooves to improve wear resistance and prevent micro-scuffing under high temperature. HDC can apply hard anodizing on forged pistons when your engine design requires extra durability.

Ceramic coating helps reduce heat transfer from the combustion chamber into the piston. It improves thermal efficiency and protects the crown in high-boost or high-temperature engines. Available through HDC’s trusted coating partners.

Technical Specifications

Discover what we can do for your custom forged pistons.

| Forging Method | Closed-die forging |

| Material Condition | Forged + T6 heat-treated (other tempers optional) |

| Diameter Range | Ø 30 mm – 120 mm (custom sizes available) |

| Height Range | 25 mm – 120 mm depending on design |

| CNC Machining | 3-axis, 4-axis, 5-axis CNC for crown, skirt, ring grooves, and pin bore |

| Weight Tolerance | ±2–5 g (depending on design) |

| Minimum Wall Thickness | 2.0–3.5 mm (depends on application) |

| Design Support | Dome, dish, flat-top, pocketing, oil gallery, lightweighting |

| Testing Capability | Dimensional inspection, hardness test, spectrometer material analysis |

| Delivery Options | Forged blanks or fully finished pistons ready for assembly |

Start Your Custom Forged Piston Project

Reach out to HDC, then you get the most expert one-stop forging product solution you can find. Just send an email, our quote is free!

FAQs

What is a forged piston?

A forged piston is a piston made by pressing heated aluminum alloy under high pressure to create a dense, strong part. It’s commonly used in high-performance engines, racing engines, and applications that need higher strength than cast pistons.

What are the benefits of a forged piston?

Forged pistons are stronger, handle higher loads, and deal better with heat and detonation. They are less likely to crack under extreme conditions, making them ideal for boosted engines, high RPM use, and heavy-duty machines.

What are the two types of materials for forged pistons?

Most forged pistons are made from:

- 2618 aluminum – high strength, good for racing and high boost

- 4032 aluminum – more stable, lower expansion, quieter for daily use

Both are good; the choice depends on power level and engine use.

What is better, cast or forged pistons?

Forged pistons are stronger and last longer in tough conditions. Cast pistons are cheaper and fine for stock engines. If the engine sees high RPM, turbo/supercharger, or heavy loads, forged is the better option.

What is a piston in automotive?

A piston is the moving part inside the engine cylinder. It goes up and down to turn combustion pressure into mechanical power. Every internal combustion engine uses pistons to drive the crankshaft.

What are the three types of pistons?

Common piston types include:

- Flat-top pistons

- Dome pistons

- Dish pistons

Each type changes compression ratio and combustion characteristics depending on the engine design.

How often should pistons be replaced?

Pistons can last many years in normal engines. They usually need replacement only when the engine is rebuilt, after heavy wear, or if damaged from overheating, detonation, or poor lubrication. High-performance engines may require more frequent inspection.Not always, but many carbon steel hinges benefit from heat treatment to improve strength and durability. Aluminum and stainless steel depend more on the specific alloy. Your requirements decide whether heat treatment is needed.

How many pistons are in a car?

It depends on the engine. A car usually has 4, 6, 8, or 12 pistons, one for each cylinder.

Does V12 mean 12 pistons?

Yes. A V12 engine has 12 cylinders, so it uses 12 pistons, arranged in two banks of six.

What is the MOQ for forged pistons?

Our MOQ depends on the piston size and material, but most forged piston orders start from 100–300 pcs. For new designs, we also support small trial batches for testing before mass production.