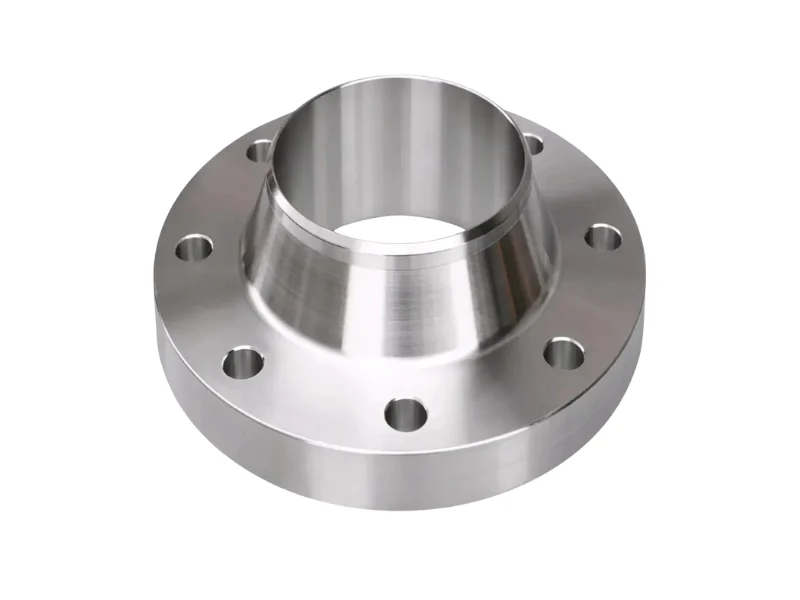

Custom Stainless Steel Forging Parts Provider

At HDC, you can customize forged products with tens of grades of certified stainless steel and post-processing options. As a forging specialist, we utilize advanced equipment and rigorous quality control, ensuring that every part meets your exacting requirements.

Simply upload your specifications and drawings, and we will offer a comprehensive quotation within 24 hours.

Industries We Serve

Automotive

High strength-to-weight ratio and temperature resistance for critical drivetrain components.

Medical

Superior biocompatibility, sterilizability, and precision for surgical tools and implants.

Food Processing

Hygienic surfaces ensure contamination-free operation in harsh environments.

Architecture

Exceptional corrosion resistance and structural integrity for load-bearing connections.

Stainless Steel We Forge

Below are the four grades of stainless steel we most commonly use for forging. For more material information, please contact us for details.

304 is not magnetic and is a standard austenitic stainless steel. It has a relatively low nickel content, around 8%, so the cost is also lower.

It is suitable for general-purpose forgings that are cost-sensitive, do not have high requirements for corrosive environment, and require good formability and weldability, such as flanges, valve bodies, pipe fittings, food processing equipment parts, building hardware, etc.

| Density (g/cm³) | Hardness (HB) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Melting Range (°C) |

|---|---|---|---|---|---|

| 7.93 | ≤ 215 | ≥ 205 | ≥ 515 | ≥ 40 | 1400–1450 |

The main components of 316 are 16-18% Cr, 10-14% Ni, 2-3% Mo, which is a molybdenum-containing austenitic stainless steel. The addition of molybdenum greatly improves its corrosion resistance to acid and salt solutions.

It is suitable for forged parts that require higher corrosion resistance, especially those exposed to seawater or chemically corrosive environments, such as marine hardware, seawater treatment equipment, etc.

| Density (g/cm³) | Hardness (HB) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Melting Range (°C) |

|---|---|---|---|---|---|

| 8.00 | ≤ 215 | ≥ 205 | ≥ 515 | ≥ 40 | 1375–1400 |

316Ti adds Ti to the composition of 316, which makes it have both the excellent corrosion resistance of 316 and the better high-temperature performance than 316. But the addition of titanium also makes it less malleable and surface quality than 316 or 304.

| Density (g/cm³) | Hardness (HB) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Melting Range (°C) |

|---|---|---|---|---|---|

| 8.00 | ≤ 215 | ≥ 215 | ≥ 520 | ≥ 40 | 1375–1400 |

The main components of 318LN are 22% Cr, 5-6% Ni, 3% Mo, 0.15-0.20% N, which is a nitrogen-containing duplex stainless steel with both austenite and ferrite. Its yield strength is about twice that of 304/316, and it has extremely high resistance to chloride ion corrosion and stress corrosion. But forging is more difficult, and the cost is higher than that of 304/316.

| Density (g/cm³) | Hardness (HB) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Melting Range (°C) |

|---|---|---|---|---|---|

| 7.80 | ≤ 290 | ≥ 450 | ≥ 620 | ≥ 25 | 1380–1440 |

Post Treatment Options

We offer comprehensive post-treatment for stainless steel forgings, including heat treatment to protective finishes.

Solution Treatment

Pickling

CNC Machining

Sand Blasting

Polishing

Forging Parts HDC Provides

HDC tailors high-precision stainless steel forgings for global customers with unmatched expertise.

Why Choose HDC

Competitive Price: We are a factory equipped with multiple automated forging production lines and in-house post-treatment process, which gives us the confidence to provide a competitive price in the market.

Scalable Production: With our 30+ forging production lines and CNC machines, we can smoothly scale from prototypes to mass production of over 10000 pieces a month.

Precision Forging: HDC is an expert in precision close-die forging, which can produce forgings with a near-net shape, efficiently reducing post-finishing. With our 5-axis machining center, we achieve a ±0.05 tight tolerance for stainless steel forgings.

Strict Quality Control: We control quality from raw material to final products with advanced testing equipment, including CMM, tensile tester, hardness tester, profilometers, and fluorescence penetration testing lines

Comprehensive Support: We provide support from design optimization, material selection, certification, to shipping. Even newcomers purchasing overseas can easily customize desired products with no hasle.

More About HDC

| Equipment | Quantity | |

|---|---|---|

| Forging | Electric screw press (160T-4000T) | 22 |

| Forging Press (160T-1000T) | 12 | |

| Punch Press | 50 | |

| Roll Forging | 1 | |

| Heat Treatment and Surface Treatment | Quenching Furnace | 1 |

| Ageing Furnace | 2 | |

| Pickling Line | 2 | |

| Polishing Line | 2 | |

| Sandblasting Line | 3 | |

| Machining | Three-Axis Machining Center | 20 |

| Four-Axis Machining Center | 23 | |

| Drilling and Milling Center | 6 | |

| Drilling Machine | 26 | |

| Honing Machine | 2 | |

| Ultrasonic Cleaning | 2 | |

| Broaching Machine | 1 | |

| Testing Equipment | Coordinate Measuring Machine (CMM) | 1 |

| Spectrometer | 1 | |

| Material Tensile Testing Machine | 2 | |

| Hardness Tester | 4 | |

| Profilometer | 1 | |

| Fluorescent Penetrant Inspection Line | 1 |

Customization Products With a Simple Quote!

We specialize in forging all major grades, including 304/304L, 316/316L, and 318. Custom alloys can be accommodated upon request with material certification

We forge parts up to 30 kg and 500mm in length. If you need larger forgings, please contact us for custom solutions.

Our standard closed-die forging accuracy can achieve ±0.3mm. With CNC finishing, we can reach ±0.05mm.

Yes, all of our materials are sourced from certified suppliers. We can provide material certificates or test reports according to your needs.

Typically 6-8 weeks after final approval.

Yes. We export to the EU, USA, Australia, NZ, Middle East, etc. Incoterms (FOB, CIF, DAP) and logistics are flexible.