Out of many aluminums, 6061 vs. 7075 aluminum is among the most commonly compared. It might have something to do with their composition, their overall structure, and even their applications.

In this blog, we’ll peek through these two classifications of aluminum. We will learn what 6061 aluminum is, what 7075 is, how they’re similar, how they’re different, and every crucial piece of information about it!

What is 6061 Aluminum?

Source: CoreMark Metals

6061 aluminum is one of the more commonly used high-strength aluminum in various industries. From aerospace, automotive, to marine and shipyard industries, they’re often the first option.

It’s made up of chromium, copper, silicon, magnesium, and of course, aluminum. Other elements in small amounts are present in the metal, too. They’re used in those industries because of their excellent corrosion resistance, machinability, and weldability.

What is 7075 Aluminum?

Source: AAA Air Support

On the other hand, 7075 aluminum is this high-strength alloy known for its toughness and lightweight properties. It is made mostly of aluminum, chromium, magnesium, and others with zinc as the primary additive.

It offers excellent resistance to fatigue and stress. This makes it a top choice for aerospace, automotive, and high-performance sporting equipment.

So how does 6061 and 7075 compare? Which one is better for your needs? Let’s go ahead and check both of them out and take a look at them side-by-side!

Read More: Aluminum 6061 vs. 6063: Know the Difference

Comparing 6061 vs. 7075 Aluminum: What’s Better?

We’ll be taking a look at 6061 and 7075 aluminum’s important characteristics and properties individually. Through that, you’ll. be able to identify what works better for your application and your needs!

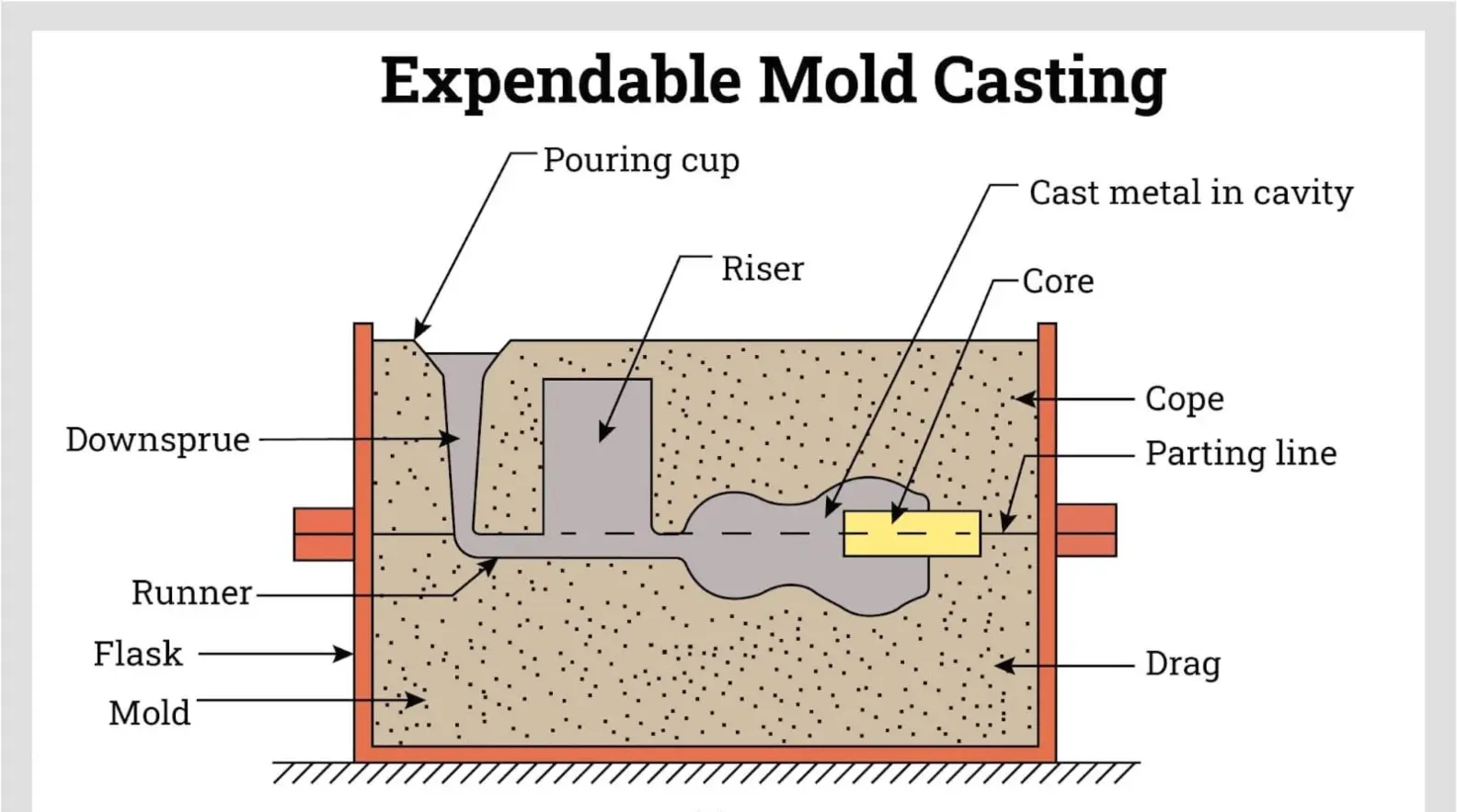

Chemical Composition

Let’s start with the chemical composition. 6061 is an alloy primarily made up of magnesium and silicon as the alloying elements, while 7075 is majorly made of copper and zinc. The differences in these alloying elements may not seem too far from one another, but they’re actually going to reflect more in their performance.

Strength

7075’s strength is almost double that of 6061. Why, you may ask? This is because of the higher concentration of zinc in the condition where they’re heat-treated with a solution then aged, otherwise known as T6 condition.

Machinability

Machinability defines how well a material responds to processes like cutting, drilling, milling, and other machining operations. Both 6061 and 7075 aluminum alloys can be machined effectively, but 6061 is generally easier to work with and more forgiving during machining.

7075 aluminum is harder and more abrasive on tools, so it requires more care and proper tooling, which is why it is often rated as having fair machinability compared to 6061.

Also Read: 304 vs. 316 Stainless Steel: How Different Are They?

Formability and Weldability

6061 aluminum offers good formability and weldability. Thanks to its magnesium and silicon content, it’s easy to bend, join, shape, and weld using common and easy methods.

On the other hand, 7075 is more challenging to weld because it has more zinc content and is not well suited for forming or welding unless it is in the annealed condition. In addition, welding 7075 requires welders to follow special techniques and settings to avoid problems in welding the alloy.

NOTE: Many professionals and experts choose fastening, adhesives, and brazing over welding when they’re dealing with 7075.

Applications

Application-wise, you wouldn’t make the mistake of using which one because of their features and performances; let’s start with 7075.

7075 Applications

Although 7075 is not the best when it comes to formability and weldability, it’s the champion over high-stress strength situations. Because of this, they’re the more trusted alloy in several industries! The following are the applications of 7075:

- Aircraft parts and components

- Aerospace

- Military industry

- Engines, gears, and shafts

- Sporting equipment

- Spacecraft

- Defense industry

6061 Applications

On the other hand, 6061 alloy is more flexible, more versatile, and are more common. This versatility compensates for its slightly lower strength than that of 7075 alloy. Many refer to as 6061 as structural aluminum because of its common use for extrusion. The 6061 alloy is commonly used in:

- Furniture

- Bicycles and other common vehicles

- Yachts

- Ships and shipyards

- Brakes

- Construction or structural applications (beams and columns, etc.)

- Industrial and manufacturing components

Read More: Exploring CNC Titanium Prosthetic Parts: Revolutionizing Prosthetics with Precision

Portability (Density and Weight Differences)

Source: Prophecy Sensor

Knowing and understanding their density and weight help in deciding whether you should go for one or the other. Although aluminum (even different alloys) have the same density, they’re still different to some extent.

7075 aluminum has a density of about 2.81 g/cm3, which is slightly higher due to its zinc content and its ability to be heat-treated, commonly in the T6 temper. 6061 aluminum has a density of around 2.7 g/cm3, close to pure aluminum because it contains a higher percentage of aluminum.

Price

And, of course, how much they are would be a critical factor in choosing between them. 6061 aluminum is usually the more affordable option and easier to source. This is why it’s a better and more practical option for many applications.

7075 is a little costlier and more expensive because of its higher strength and added processing. Therefore, they’re often only used when that extra performance is truly needed.

Get World-Class Quality Aluminum From HDC

Are you in the market for 6061 or 7075 aluminum? Can’t find a manufacturer that you can trust and bank on? If you answered yes, then you’re just in the right guide!

HDC is China’s best and most trusted aluminum manufacturer since the early 2010s. We’ve manufactured and produced the best and highest quality of aluminum parts and components to businesses.

Whether you’re looking for high-quality aluminum, stainless steel, plastic, or whatever product, or if you are looking for whatever CNC processing, don’t hesitate to contact us! We’ll get you a free estimate!