Carbon Steel and Alloy steel are two of the most commonly used steels in the industry. These alloys are used for a variety of applications in the industry including applications ranging from construction to manufacturing of automotive parts. Although there are a number of similarities between Carbon Steel and Alloy Steel, there are some critical differences. These differences exist in their chemical composition, physical properties, and applications that we will discuss in this article.

What is Carbon Steel?

Carbon steel is an iron-carbon alloy. The carbon content typically ranges from 0.12% to 2.0%. Unlike alloy steel, it has minimal or no significant amounts of other elements. Due to the higher presence of carbon content, it is easier to determine and explain the properties of carbon steel.

Types of Carbon Steel

Carbon steel is divided into three main categories based on its carbon content:

- Mild Steel (Low Carbon Steel):This type of steel contain up to 0.25% carbon. It’s composition is relatively soft, malleable, and easy to weld. The A36 carbon steel is a popular grade of mild steel known for its versatility and ease of welding.

- Medium Carbon Steel:With 0.3% to 0.6% carbon, medium carbon steel offers a balance between strength and ductility. This type of carbon style is often categorized as Carbon steel 1045 and 1055. Due to its properties, the medium carbon steel is a common choice for automotive parts and machinery.

- High Carbon Steel:The high carbon steel consists of the highest composition of carbon with content ranging up to 0.6% to 1.0%. Due to its hardness and strength, it is most commonly used in cutting tools and blades. Examples include 1095 high carbon steel, which is popular in knife-making due to its edge retention and durability.

Each of the carbon steel categories have their own unique features that make them ideal for different applications.

What is Alloy Steel?

On the other hand we have the Alloy steel. In addition to carbon content, Alloy Steel also has other elements such as Chromium, Nickel, and Molybdenum. Due to the presence of these metallic traces in the alloy, the properties of alloy steel vary accordingly. Variations are observed in specific properties such as strength, toughness, and corrosion resistance. This variability makes alloy steel highly adaptable and valuable in a range of industries.

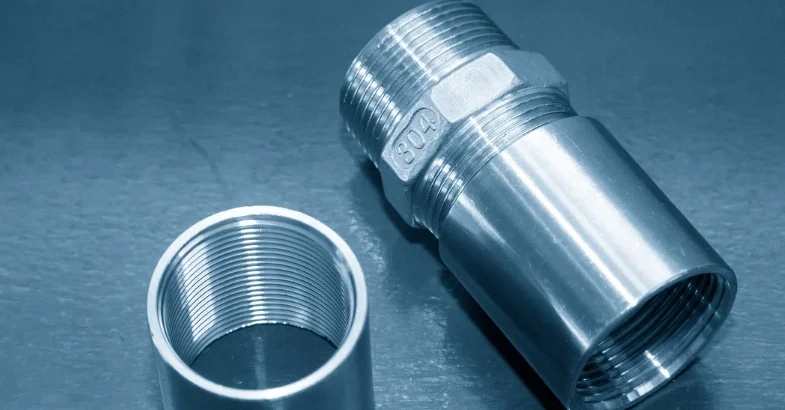

Alloy Steels are characterized by proportion of alloys in the final mix. For example, chromium-alloyed steel is widely used for stainless steel applications due to its rust resistance. Whereas, nickel alloys are commonly used for high-strength applications.

Comparing Alloy Steel vs. Carbon Steel

Let’s break down the differences between alloy steel and carbon steel based on several key characteristics:

Composition

- Carbon Steel:Primarily consists of iron and carbon. Usually, no other elements are present, however, if any other elements are present they are present in very small quantities.

- Alloy Steel:Alloy steels usually contains additional elements such as chromium, nickel, and manganese that impact the final properties of the steel.

Strength and Hardness

- Carbon Steel:As the proportion of carbon content increase in the alloy, the strength and hardness goes up. For example, the mild steel is softer and lesser in wear-resistance as compared to hard steel.

- Alloy Steel:Alloy Steel us usually suitable for heavy-duty applications. Furthermore, you have the capability to customize the final properties of the steel. This allows you to increase the strength of the alloy steel further. Alloy Steel is suitable for heavy-duty applications like pipelines and structural components.

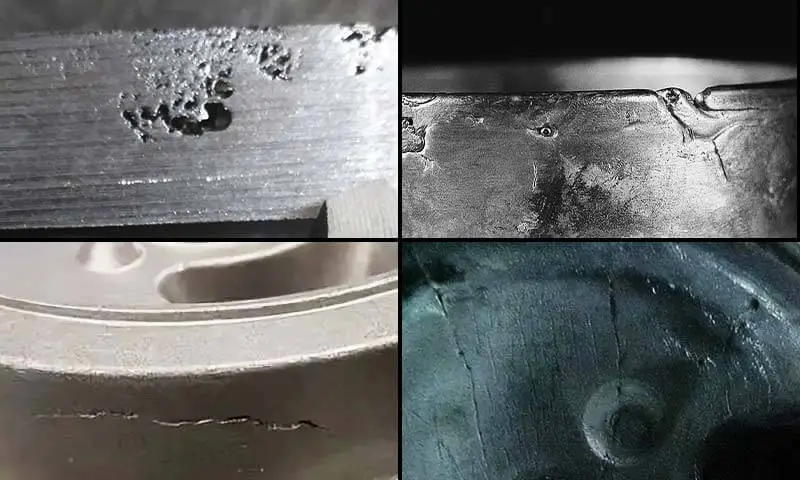

Corrosion Resistance

- Carbon Steel: One of the common questions in the industry, “Does Carbon Steel Rust? The answer is yes. If the carbon steel is left without protective coating, the steel may catch rust. It is also a fact that high carbon grade steel are more susceptible to rust.

- Alloy Steel:Alloy Steels are usually better at handling rust. For instance chromium alloy steel has a protective layer of oxide that protects it against corrosion and rust. Therefore, making the Alloys as better resistant to environmental impacts and chemicals.

Weldability

- Carbon Steel:Carbon Steels, usually, Mild steel is easy to weld, while high carbon steel requires more precision due to its higher melting point.

- Alloy Steel:Alloy steel’s weldability varies based on its composition. For example, welding stainless steel to carbon steel requires specialized techniques due to their different properties.

Cost

- Carbon Steel:Carbon Steel is generally more affordable than Alloy Steel as the production cost is lower.

- Alloy Steel:The cost varies depending on the elements added to the alloy. However, the addition of expensive and rare elements make such alloys more expensive than carbon steel.

Carbon Steel vs. Stainless Steel:

The most common type of competition is between the carbon steel versus stainless steel. Both have unique advantages depending on the use case:

- Corrosion Resistance:Since Stainless steel has chromium content which makes it less susceptible to rust. On the other hand, carbon steel requires paint coating or preventive maintenance to protect against rust.

- Hardness and Sharpness:In terms of hardness/sharpness, Carbon steel grades like 1095 and 1060 carbon steel are popular in knife-making and other precision cutting tools.

- Ease of Maintenance:Carbon steel equipment requires a little maintenance, however, stainless steel knives are easier to maintain.

For a practical example, a carbon steel cooking knife provides excellent edge retention and sharpness but needs extra care to avoid rust. A stainless steel knife, while less sharp, is more rust-resistant, making it suitable for wet environments.

Practical Applications

- Construction:Mild steel (a low carbon steel grade) is a common choice when it comes to structural applications. This is because of its malleability and weldability.

- Automotive Applications:Medium carbon steel grades like 1045 carbon steel are preferred for automotive parts requiring both strength and ductility.

- Tools and Blades:High carbon steel, such as 1095 high carbon steel, is ideal for cutting tools due to its hardness and edge retention.

- Industrial Equipment:Alloy steels with specific elements (like chromium or molybdenum) offer the strength and corrosion resistance that is required for high wear and tear environments and areas exposed to high-pressure.

Frequently Asked Questions About Carbon Steel

Is Carbon Steel Safe?

Yes, carbon steel is safe for many uses, including cookware. However, it requires seasoning to prevent rust and to maintain a nonstick surface in cooking applications.

Is Carbon Steel Magnetic?

Yes, carbon steel is magnetic due to its high iron content. This makes it useful in magnetic applications.

How to Clean Carbon Steel?

Avoid using acidic or abrasive cleaners while clearing carbon steel. When dealing with cookware, prefer hand washing with mild soap and drying immediately. Oiling at regular interval will help in preventing rust formation.

Can You Weld Stainless Steel to Carbon Steel?

Yes, welding stainless steel to carbon steel is possible but requires specific techniques. Furthermore, considerations are to be given to manage the differing properties of the two and to prevent corrosion at the joint.

Conclusion: Choosing Between Alloy Steel and Carbon Steel

Summing up, no one material can be said to be one-fits-all industrial solution. Each of the material has its own pros and cons when used for different applications. For instance, Carbon steel is affordable and versatile, suitable for many structural and tool applications. Also, Carbon Steel offers strength and hardness at a very competitive price. On the other hand, Alloy steel, with its customizable properties, are ideal for environments that demand high corrosion resistance, toughness, and high strength.

Understanding the differences in carbon steel grades, such as 1018 carbon steel, 1045 carbon steel, or 1095 high carbon steel, helps in selecting the right material.

Ultimately, whether it’s carbon steel sheet metal for construction or high carbon stainless steel for industrial equipment, each steel type offers unique benefits that cater to specific demands.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!