As one of the most common metal materials, aluminum is a suitable choice for laser engraving, due to its high thermal conductivity and excellent corrosion resistance. Nowadays, aluminum laser engraving is an indispensable technique that provides feasibility for design inspiration in various industries. If you want to know whether and how aluminum laser engraving can create more advantages and possibilities for your product design and customization projects. After reading this article, you may find the answer.

Principle of aluminum laser engraving

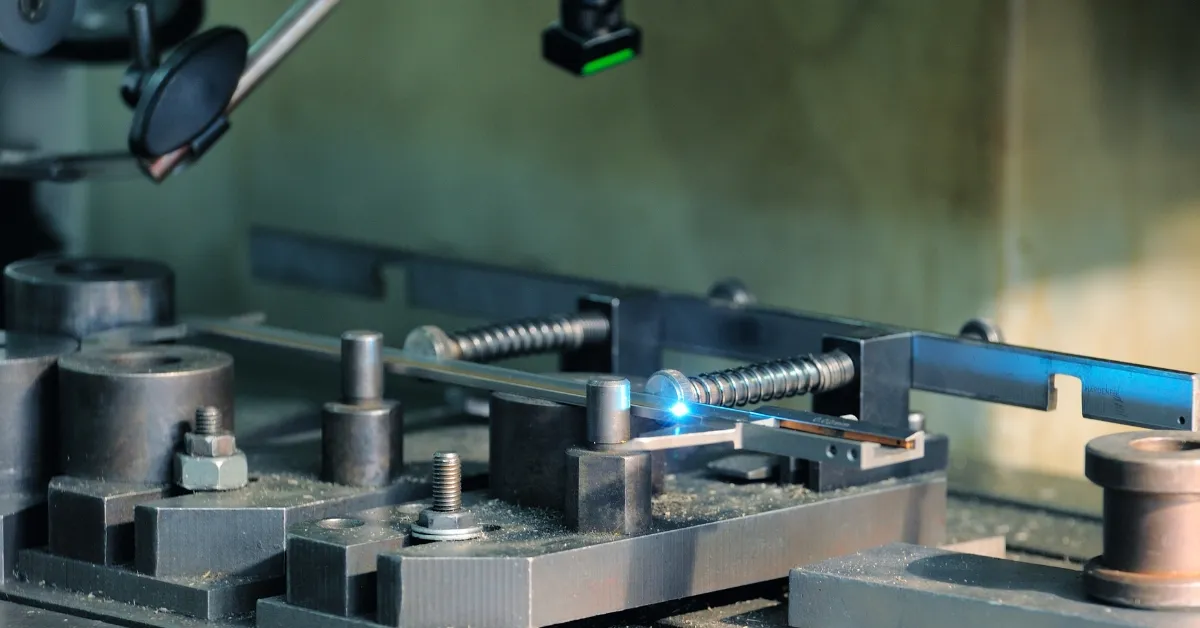

Aluminum, as a good thermal conductor, can effectively absorb the heat generated by a high-density laser beam when focused on its surface.

When the temperature in the laser-irradiated area reaches aluminum’s boiling point (2470 ℃), surface particles begin to vaporize, thus carving out precise and intricate patterns.

Aluminum surface finishing and laser engraving effects

The laser engraving effect on aluminum material does not depend on the type of substrate, but rather on its surface finishing condition. Here are three kinds of aluminum with different surface treatments that are commonly used for laser engraving:

Anodized aluminum

Based on the anodizing process, the thickness of the anodized layer typically ranges from 5 ~ 60 μm, while the commonly used fiber laser engraving only reaches a depth of 0.2 – 1 μm.

Therefore, the laser doesn’t remove any base material, but only alters the aluminum oxide layer.

Typically, uncolored anodized aluminum produces dark gray markings, colored anodized aluminum produces black markings, both are clear and high-contrast.

Bare Aluminum

Bare aluminum is natural aluminum without any surface treatment, making the cost relatively inexpensive. Laser melts bare aluminum and carves out patterns that have subtle contrast but are permanent.

It should be noted that due to aluminum’s low hardness and heat sensitivity, it is necessary to adjust the appropriate parameters and speed of laser engraving to control quality.

Powder-coated aluminum

Powder-coated aluminum is sprayed with plastic polymers (such as epoxy resin or polyester), allowing for various colors to be applied. Laser ablates and vaporizes the coating, exposing the underlying aluminum to create a contrasting pattern.

This offers a colorful appearance for designs, being cost-effective and environmentally friendly. However, the coating is not wear-resistant, which may affect the engraving quality.

Types of laser engraving machines for aluminum

According to the different media that generate lasers and the laser wavelengths, there are many types of aluminum laser engraving machines. Choosing the correct type of laser is crucial for the effect of aluminum engraving.

Fiber laser

Fiber laser has a wavelength of 1064nm, which can reach an absorption rate of about 4–10% by aluminum, making it ideal for engraving on all types of aluminum. For projects that require both engraving and cutting, a fiber laser cutting machine provides versatility, allowing high-quality processing of aluminum parts.

If you need large-scale, high-quality and detailed laser engraving on aluminum, a fiber laser engraver is the best choice.

CO₂ laser

CO₂ lasers (10.6µm wavelength) generate laser light using carbon dioxide gas. Due to the low absorption rate for bare aluminum, they are more suitable for aluminum that has undergone surface treatments (such as anodizing and powder coating).

CO₂ laser engraving can maintain the integrity of the material, but because it requires low speed and high power settings, its run time and cost are relatively high.

Diode laser

A diode laser is generated by a semiconductor diode, with wavelengths ranging from 450nm to 900nm. It is mainly used for anodized aluminum and powder-coated aluminum.

Due to their slower engraving speed and limited depth capability, diode lasers are only suitable for small batch design projects with shallow engraving depths.

Application of aluminum laser engraving

Aluminum, as a lightweight, strong, and corrosion-resistant metal, is one of the most favored materials across various industries, from aerospace to custom services. Laser engraving offers more possibilities for aluminum parts processing with its advantages, such as high precision and durability.

Industry and Manufacturing

Laser-engraved markings on aluminum are clear, durable, and resistant to wear, making them ideal for engraving part numbers, serial numbers, or traceability codes on components used in harsh environments, such as aircraft parts, auto parts, and high-end tools and equipment.

Electronic accessories

Due to the pursuit of lightweight, many electronic product parts are now made of aluminum, so aluminum laser engraving is often used to engrave serial numbers, configuration information, traceability codes, logos, etc. For example, the MacBook logo we know is engraved with a laser.

Art and high-end consumer goods

Because of its high-end and modern texture, aluminum laser engraving is often used for personalized, customized products and artistic decoration, such as laser engraved aluminum nameplates, medals, decorative panels, etc.

Benefits of aluminum laser engraving

Permanent and durable

Laser engraving creates marks by melting or vaporizing the designated area of aluminum, rather than simply printing on the material surface.

Therefore, the engraved mark is durable and indelible. Even if the aluminum is subsequently subjected to surface treatment such as anodizing, the mark remains permanent and wear-resistant.

High precision and excellent quality

Laser engraving on aluminum can achieve extremely fine lines( reach micron level) that ensure detailed and intricate pattern designs appear clearly and precisely.

Non-contact and material protection

Aluminum laser engraving uses the thermal energy generated by lasers to accomplish engraving processing, without the need to touch the surface of the parts.

This non-contact protects the integrity of the parts, eliminating the risk of deformation and fracture.

Highly efficient and automated

Aluminum laser engraving is driven by computer software control, which can meet large-scale industrial production in a single operation.

Since the machine control allows for fully automated marking, it reduces labor costs and avoids manual errors. This not only ensures timely and fast delivery but also guarantees production efficiency and accuracy.

Economical and environmentally friendly

Laser engraving on aluminum is an eco-friendly, pollution-free processing technology. As long as the software design is set correctly during the engraving process, there will be no material waste.

The entire processing only requires a laser machine and aluminum material; it does not need to use inks, solvents, or other consumables, nor will it produce harmful chemical waste. Therefore, aluminum laser engraving is an economical and environmentally friendly option.

Conclusion

Aluminum laser engraving, as an efficient and high-precision technique, plays an important role from personalized products to industrial manufacturing.

It is also widely applied in the field of CNC machining. HDC can provide a one-stop metal solution service with aluminum laser engraving. If you are looking for a reliable CNC manufacturer for your custom needs, please feel free to contact us.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!