Revolutionizing RC Cars: The Impact of CNC Machined Parts

Dive into the world of CNC machined RC parts and discover how this cutting-edge technology enhances the design, performance, and aesthetics of remote-controlled vehicles. From chassis to gearboxes, explore how CNC parts are transforming the RC hobby.

Basic Information About Piano Hinge:

What is a Piano Hinge?

A piano hinge, alternatively referred to as a continuous hinge, manifests as an elongated, slender hinge boasting an assemblage of interlocking leaves. It runs throughout the length of the lid/door. This way the amount of load is evenly distributed throughout the hinge enabling it to carry higher loads. The nomenclature “piano hinge” derives from its frequent deployment within the confines of piano lid assemblies.

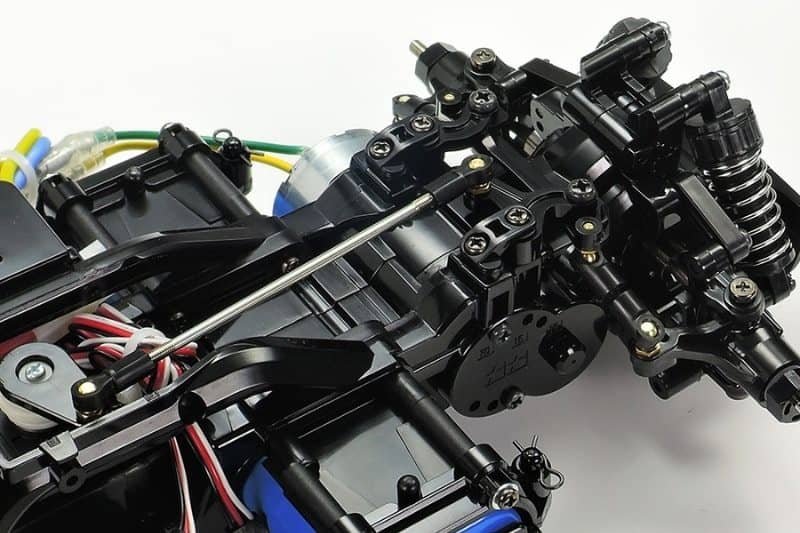

Understanding CNC RC Parts

CNC RC parts are manufactured with computer numerical control (CNC) machining being some of the components for a remote controlled vehicle. CNC machining, also referred to as computer numerical controlled or programmable machine tool is a process that uses mechanized software and electrical equipment for shaping materials. Currently, CNC machining offers quality and tailor-made parts for applied use in remote controlled cars including RC planes, airplanes helicopters boats, drones among other types of RQs.

Different Types of RC Cars

Some of the most common CNC RC components are lightweight and tough chassis frames, suspension elements such as shock towers and arms gluts roll wheels with a perfectly precise hubs engine / motor mounts centered for alignment geared differential boxes drivetrain parts – power translation servant servos’ kinesthetic edges driving arm control. Moreover, fans may apply CNC machining to manufacture special custom parts; they can create such individual restoration components as particular body elements or challenge shock absorber platings aimed at the specific RC projects.

RC Parts Can Be Manufactured Using CNC Technology

Virtually all RC parts can be manufactured using CNC technology, including suspension arms, chassis, shock towers, and steering components. This technology allows for customization, resulting in parts that suit specific RC car models.

Benefits of Choosing CNC for Manufacturing RC Parts

Many advantages can be enjoyed incase CNC machining is used on the production of RC parts. CNC machining ensures a precision-accurate process with repetitive production of similar quality parts. While serving this accuracy, the performance and maneuverability are increased. Therefore CNC – machined parts can be lightweight but at the same time resistant, which makes the car lighter and more manoeuvrable while lengthening its life. Moreover, with CNC technology parts can be specialized which means an enthusiast will not only find a product capable of meeting his/her requirements but also one that is suitable for the needs and desires. In addition, CNC machining is highly able to be used for high intricacy geometries and designs which create more complex suspensions components such as the gearboxes or transmission parts that help transfer power efficiently. CNC machining capitalizes and consolidates the quality, performance, as well customized options for RC fans.

Materials Typically Used to Make CNC RC Parts

The common materials utilized in the making CNC RC parts include light but strong choice such as aluminum, carbon fiber material steel and titanium. Some parts are low-friction components, and Delrin is used in such cases; brass adds weight plus corrosion resistance to certain additional elements. Components that are not used for the construction behavior of structures such as non-structural load bearing, composite materials are implemented to obtain special features about properties and characteristics similar to what is present in drones propellers. Every aspect of matter is selected depending upon the specific requirements that supports by having strength, weight and other endurance qualities to make RC vehicles even more perfect.

Finishing Options Available for CNC RC Parts

Finishing options for CNC RC parts include anodizing in aluminum parts, powder coating of durable level and color customizations among others but finishing is dependent on taste or application hence; painting unlimited possibility to the style such as polishing a shiny surface with cut friction plating corrosion resistance plus style bead blasting unique matt finish clear coatings protection brilliant look not forget Within the context of aesthetics, functionality reading and comprehension. improvement and project specification to optimize appearance performance as well as durability manages desire function be finished material.

CNC RC Parts Enhance Performance and Handling Experience

RC parts manufactured using CNC add essential value to the performance and handling of remote-controlled machines. Custom machined product utilizes materials like aluminum, carbon fiber and titanium elements that allow lightweight but strong solutions which increase agility together with cement structural integrity. CNC made suspension parts, gearboxes and drive train components guarantee effective transmission of power while providing improved control. In addition to that, the customization features enable vehicle enthusiasts personalize their RC vehicles with special additions of various accessories thereby improving in performance on distinct needs. Fundamentally, CNC RC pars significantly improve the high-quality and accurate driving experience offered by a radio control car.

Parts That Can Significantly Improve the Performance or Handling of an RC Car

There are several key components that can drastically influence the practical performance and handling of an RC car, such as suspension elements for stability on different terrains, higher-quality tires and molded wheels providing better grip together with a more powerful motor Combined ESC is translated into increased speed pace time which also increases the acceleration rate among others including upgraded molecules And cnc machinists ch Proper configuring the right matching of these parts and appropriately adjusting can significantly improve an RC car’s overall performance in handling.

Guidance for Custom CNC RC Parts

Customizing CNC RC parts is a straightforward process. You have the flexibility to select specific designs, colors, and finishes that align with your preferences and make your RC car truly unique. At HDC, we’re here to assist you throughout the entire customization journey. As an experienced custom CNC parts company, we boast a well-trained design and production team, which instills in us the confidence to craft the perfect RC parts tailored to your needs.

Usual Customization Options for CNC RC Parts

The CNC RC parts provide a broad scope of modifications to suit the needs and specific interests of enthusiasts. Such standard customization measures involve doing part dimensions for a perfect fit, selecting the materials wanted based on strength and weight properties apart from fixing some personalised designs or logos using CNC machining including laser etching. In addition to this choosing surface finish such as anodising and powder coating will help you of aesthetics and other aspects protections issues moreover adding extra features like cooling The precision and flexibility of CNC machining allow the user to produce custom parts that improve appearance but also performance, so every single individual receives a dash reserved exclusively for him only.

CNC RC Parts Enhance Aesthetics

The CNC RC parts not only increase the functionality but significantly promote the appearance of remote controlled cars. These machined components are customizable to have detailed designs, logos and patterns thus improving the looks of an rc car plane or drone. Further, there are several surface finishes like anodizing or powder coating that offer different types of colors and textures thus enabling the enthusiasts to make their RC monitor-looking vehicles. CNC machining is an indispensable tool in achieving a model RC that performs better and looks even more beautiful than the original, which only benefits hobbyists and enthusiasts when they enjoy their new improved models.

Conclusion

CNC RC parts have revolutionized the world of RC cars by offering precision, performance, and customization. These components, crafted with CNC technology, are a must-have for any RC enthusiast looking to take their car to the next level. Whether you seek improved performance or want to make your RC car visually appealing, CNC RC parts have you covered.

Resources:

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!