Forging vs Billet: Which One is Stronger, Cheaper & Better in 2026?

- By: HDCMFG

In forging vs billet, the options that you have to make are towards the strength, cost, and flexibility. The two processes are from automotive, industrial, aerospace, and performance parts. In 2026, due to increasing material prices and more strict quality requirements, it is necessary to choose the appropriate manufacturing process that would guarantee performance, durability, and long-term value.

We can put it all down in a practical manner so that you may make your decision.

1. Forging vs Billet: Comparison Overview

Should you require a quicker answer, the following is it:

- Forging provides greater strength and life.

- Billet is more accurate and free in design.

- Forging is used to make high volume and high-stress applications.

- Billet is best used with personalized, low-volume, or complicated designs.

Now we shall consider each of the processes in more detail.

2. What is Forging?

The process of meta forging involves hammering of metal into form by means of extreme force. This pressure does not only affect the outward appearance but also the inner construction of the metal as it increases the strength, longevity, and failure resistance.

How the Forging Process Work?

Forging is done using metal that is heated to a desired temperature or cold metal, which is shaped in advance for use. The manufacturers put the material between dies and press it with the help of a mechanical or hydraulic process. This force shapes the metal to the required shape.

The grain structure of the metal is oriented on the geometry of the part as the metal flows. This increases the component in the precise direction of loads. Open-die forging is used in large or simple parts, whereas closed-die is used in high-volume production requiring precision and repeatability.

Common Materials Used in Forging

Forging is particularly effective with the material that takes advantage of grain refinement, such as

- Aluminum Alloys: To achieve lightweight strength (consider 6061 or 7075).

- Carbon & Alloy Steel: To be used on heavy-duty structural parts.

- Stainless Steel: In cases of high temperature and corrosion.

- Titanium: The aerospace and high-performance gold.

These materials are compression responsive and are also superior in their mechanical properties after forming.

Key Advantages of Forged Parts

Fake components offer a number of performance benefits:

- Superior Strength: The flow of grains without interruption gets rid of the weak points.

- Fatigue Limit: Forged components can be used in applications that are under stress millions of times without cracking.

- Impact Tolerance: They are able to absorb a blow that would otherwise kill other components.

- Internal Voids: The pressure forces the air bubbles out so that the interior is solid.

Forging produces parts with no weak areas because they are not cut and instead are compressed, which contributes to the part’s reliability.

Common Applications of Forging

Forging helps in industries that have no room to fail, such as

- Car suspension, steering, and drivetrain systems.

- Landing gears are structural brackets of aircraft.

- Industrial shafts, gears, and flanges.

- Severe construction and mining machinery.

These applications require constant stress performance.

3. What is Billet Manufacturing?

Parts made through Billet manufacturing are made by machining a solid block of metal. This process is aimed at precision and accuracy instead of redefining the grain, as well as flexibility in design.

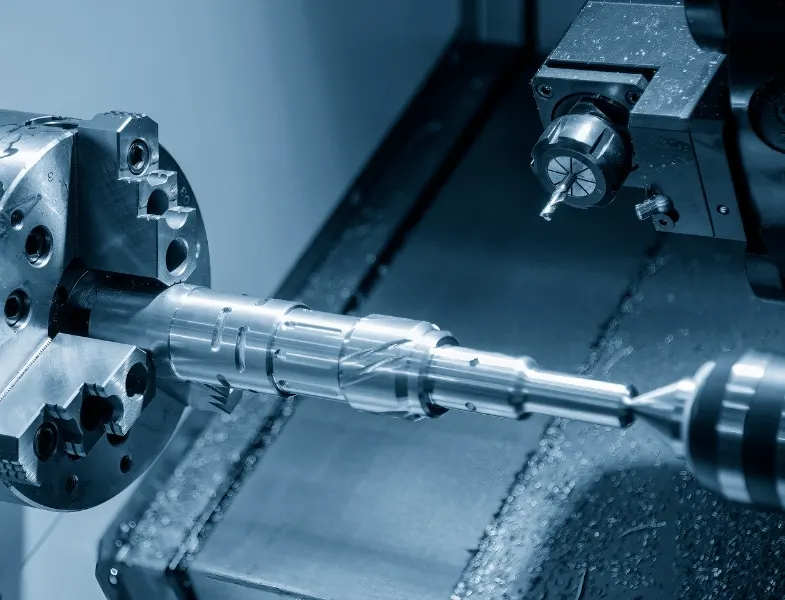

How Billet Machining Works

It is based on a 5-axis CNC machining. As you will be beginning with a standardized “billet” (a solid bar or rectangular block of material), you will not need costly custom molds or dies. The machine traces a digital CAD file to cut out complex cooling fins, internal channels, or even aesthetic designs that would have been impossible to free up using a forging die.

Common Materials Used in Billet Parts

The common uses of billet machining are

- Lightweight and precision components made of aluminum.

- Moderate strength and rigidity steel billet.

- Specialty and custom decorative and brass alloys.

These are machinable materials and have consistent tolerances.

Key Advantages of Billet Parts

The manufacture of billets has a number of advantages:

- Extreme Precision: Forging cannot even provide tighter tolerances than this.

- “Jewelry” Finish: Parts of the billet emerge exquisite out of the machine.

- Free Tooling: You do not have to go and spend $10,000 on a metal die to begin with.

- Unlimited Flexibility: A complex geometry that a mold can never deal with is no problem to a 5-axis CNC.

Such strengths put billet in a good position to be applied in projects that are innovative.

Common Applications of Billet Components

Billet parts are generally found in:

- Tailor-made automotive brackets, housings, and mounts.

- Components of the performance engine and transmission.

- Short-run prototypes and production.

- Parts of finishes that can be seen or observed.

4. Forging vs Billet: Strength Comparison

Which One Is Stronger and Why?

Forged components are also stronger than billet components, since the flow of metal grains is in accordance with the shape of the item. This flow of natural grains enhances the distribution of loads, maximizes resistance to impact, and minimizes the stress concentration in weak areas.

Billet parts are cut perpendicular to parts of the grain structure during machining. Although they are robust and good in a variety of uses, they do not perform as well as forged components in loads involving extremes, sudden stresses, and sustained stress.

Fatigue Resistance and Durability

Forged parts are much better in fatigue resistance in repeated stress cycles. They are rigid to vibration, shock, and continuous loading, and therefore they are applicable in high-stress conditions.

Billet parts are good under moderate-duty applications and under controlled environments. Yet, they are more likely to wear out faster in case of constant cyclic loads or strenuous working conditions.

5. Forging vs Billet: Cost Comparison in 2026

Forging vs Billet debate on the costs is strongly dependent on the volume of production, the tooling and the long term usage.

Which is Cheaper for Mass Production?

Forging is more expensive to initially invest in die making. The unit cost will be considerably reduced once production starts. Forging is less expensive in the long run when it is applied in large-scale production.

Cost of Billet for Small Batches and Custom Parts

Billet machining eliminates the use of tooling. Production can be started at once. With small batches, prototypes, or the need to do a lot of design changes, billet can be cheaper even though it may take more time to machine.

Overall Cost Efficiency Breakdown

- 1-50 Units: Billet is nearly always cheaper.

- 500 and Above: Forging begins to save you large sums.

- Massive volume and power requirement: Forging.

- Low volume + customization: Billet.

- Long life performance: Forging.

- Short-term flexibility: Billet.

6. Forging vs Billet: Performance in Real-World Use

Heat Resistance and Structural Stability

Forged parts have the strength to withstand heat and do not deform when exposed to heat and pressure. Their high quality grain structure ensures that they remain stable in harsh thermal environments, e.g heavy machinery or performance cars.

Billet parts can withstand normal operating temperatures. They, however, lose their structural stability earlier in extreme temperatures, particularly when coupled with high mechanical loads.

Weight Optimization and Material Efficiency

Forging enables the creation of thinner parts without any loss of strength, which lowers the total weight of the parts and still does not affect performance. This renders forging perfect where the strength-to-weight ratio is considered.

Particular parts of bills usually demand additional material to ensure safety stocks. This adds total mass and may restrict the efficiency in mass-sensitive designs.

7. Forging vs Billet: Manufacturing Flexibility

Design Freedom and Customization

Billet machining has an unsurpassed freedom of design. You are able to develop complicated geometries, tight tolerances, and finer detailing, and you are able to make changes faster without extra tooling.

Faking restricts the ability to change after the tooling is complete. Modifications in design often involve new dies and this is more expensive and time-consuming.

Production Speed and Scalability

Billet is faster than prototyping, testing, and short production. It enables quick turnaround in instances where designs change regularly.

Forging is quite effective in high-volume production. When tooled, it provides repeat quality shorter cycles, and also reduced per-part cost scale.

8. Forging vs Billet: Pros and Cons Table

Feature | Forging | Billet |

Strength | Extremely high | High |

Fatigue life | Excellent | Moderate |

Precision | Moderate | Very high |

Customization | Limited | Excellent |

Cost (high volume) | Lower | Higher |

Cost (low volume) | Higher | Lower |

9. Forging vs. Billet: Which One Is Better in 2026?

Best Choice for Automotive and Performance Parts

Forging of suspension, drivetrain, and safety-significant parts subjected to perpetual stress, vibration, and collision. Components such as control arms, knuckles, gears, and connecting rods enjoy the advantages of the flow of forged grain, which enhances strength, fatigue life, and reliability to perform at high speed or heavy load capacity.

Best Option for Industrial and Structural Applications

Forging imparts a life span, security, and reliability to industrial gear and infrastructure. Forged items like shafts, flanges, couplings, and load-bearing brackets are better as far as they do not crack, deform, and fail due to continuous loads and during the severe operating conditions.

Best Solution for Custom and Low-Volume Projects

Billet machining is used with prototypes, custom parts, and precision-oriented designs that are more concerned with flexibility than sheer strength. It enables rapid design alterations, narrow tolerances, and intricate shapes and is therefore suitable for brief production periods, specialty part production, and those that have to be visually revealed.

10. Forging vs. Billet: Which One Do Engineers Prefer?

As an engineer, it would be possible to discuss the following:

- The load-bearing and safety-critical parts are to be forged.

- Billet would be used where there are tight tolerances, packaging requirements, and design validation.

A hybrid approach is used in many of the modern projects:

- Billets to be prototyped and tested.

- Right welding to mass production.

It is a low-risk, cost-saving, and performance optimizing plan.

11. Forging vs. Billet: Which One Should You Choose?

Choose forging when:

- What is important is strength and durability

- It requires high-volume production

- Parts face constant stress

Choose billet when:

- Custom or complex designs are required.

- Production volume stays low.

- Appearance and precision are important.

12. Final Thoughts: Forging vs Billet in 2026

The debate about forging vs billet does not have a common-place winner. The correct decision will be made depending on the use of the parts, the number of units required and the period it has to be used.

- Select forging as strong, durable, and reliable over the long term.

- Select billet to be accurate, flexible, and developed fast.

We do not impose either of the methods at HDC. We study your application, loads, volume of production, and your budgets in order to suggest the most trustworthy and affordable solution. In case you need components that would work as you desire in the real-life context, our team is able to assist.

FAQs: Forging vs Billet

1. Is forged aluminum stronger than billet aluminum?

Yes, forged aluminum would have finer grains and greater fatigue strength.

2. Why do custom parts use billet instead of forging?

The design changes and complex shapes can be done quickly with no tooling expenses required in billet.

3. Does forging reduce material waste?

Yes, forging is more efficient than billet machining in terms of material.

4. Which method handles vibration better?

Forged components are much better at vibration and cyclic loads.

5. Is billet machining outdated in 2026?

No, a billet is required when precision prototypes and custom designs are required.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant free quote!