If you’ve ever wondered about galvanized steel vs. aluminum, and you’re eager to know how similar they are or what differences they have, we got you!

We’re not here to bore you with details you already know. Instead, we’ll give you in-depth analysis and comparison to help you understand the differences between them at a higher level!

What is Galvanized Steel?

Source: Monnig Industry

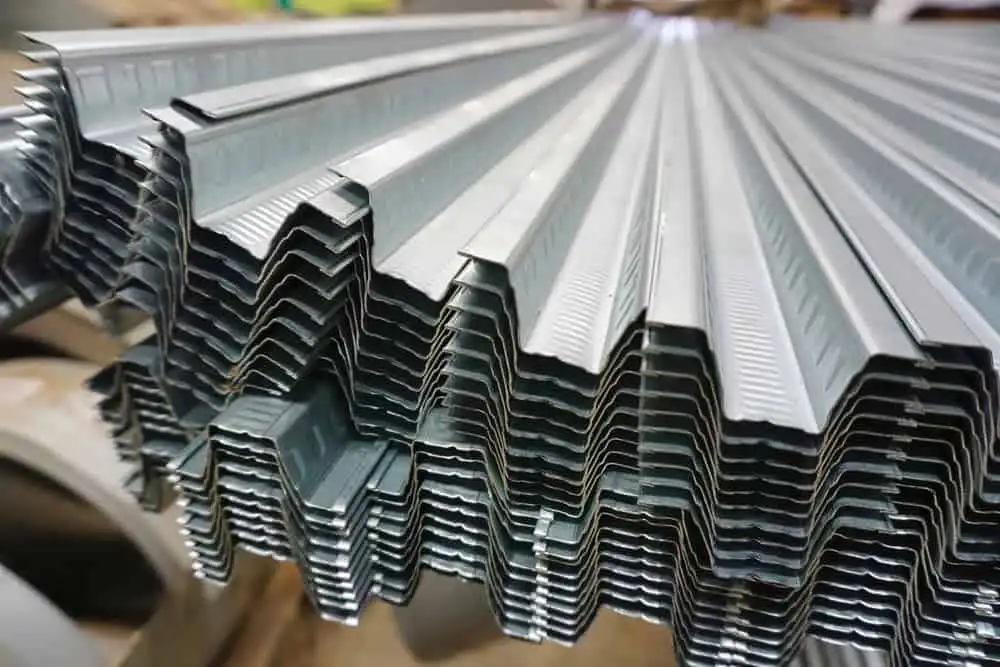

In the simplest and easiest way to explain it, it’s a carbon steel coated with a protective layer of zinc; this is to prevent rust and corrosion. Furthermore, this coating is applied through hot-dip galvanizing or electro-galvanizing, forming the barrier shielding the steel from moisture and environmental damage.

Galvanized steel is often used in applications like outdoor structures, fencing, and heavy-duty frameworks where protection against the elements is essential.

What is Aluminum?

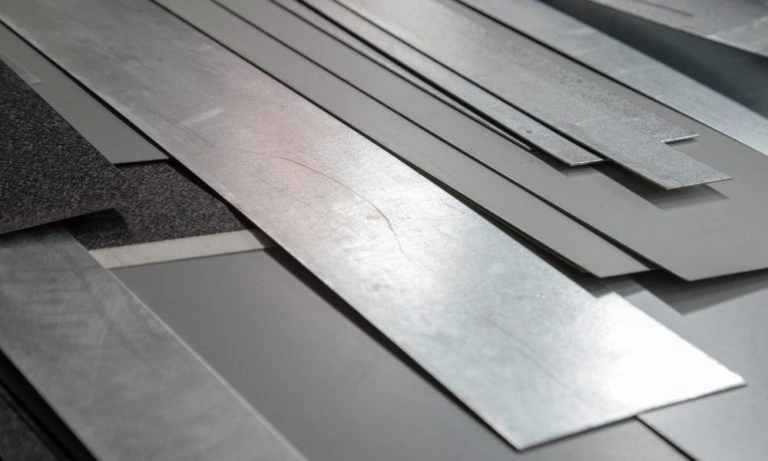

Source: Thin Metal Sales

Then, on the other side of the playing field is aluminum. It is a lightweight, corrosion-resistant metal known for its strength and versatility. Aluminum naturally forms a protective oxide layer, preventing rust without additional coatings.

Although aluminum is softer than steel, it still has a high strength-to-weight ratio, facilitating shaping and transportation. It can still corrode in specific conditions but does not rust like galvanized steel–we’ll talk more about this later.

Aluminum is frequently used in siding, roofing, and structural elements because it is low maintenance, recyclable, and resistant to rapid deterioration in outdoor environments.

Galvanized Steel vs. Aluminum: The Faceoff

Strength, corrosion resistance, cost, and application all play a role in the decision between galvanized steel and aluminum.

Despite their widespread use in the manufacturing, automotive, and construction sectors, they differ in ways that affect how well they operate and work in different settings.

Chemical Composition

Let’s start with the most exterior factor–composition, what they’re made of. This is for you to know better what their each of their capacities are.

Galvanized steel is carbon steel with a zinc coating that protects against rust. Aluminum, on the other hand, is a naturally corrosion-resistant non-ferrous metal that naturally forms a protective oxide layer.

Coating

Galvanized steel gets its protective zinc layer either through hot-dip galvanizing or electro-galvanizing, helping slow down corrosion. However, once this layer wears off, the steel underneath is exposed to rust.

On the other hand, aluminum does not require a coating—the oxide layer regenerates on its own when scratched, ensuring long-term protection.

Strength

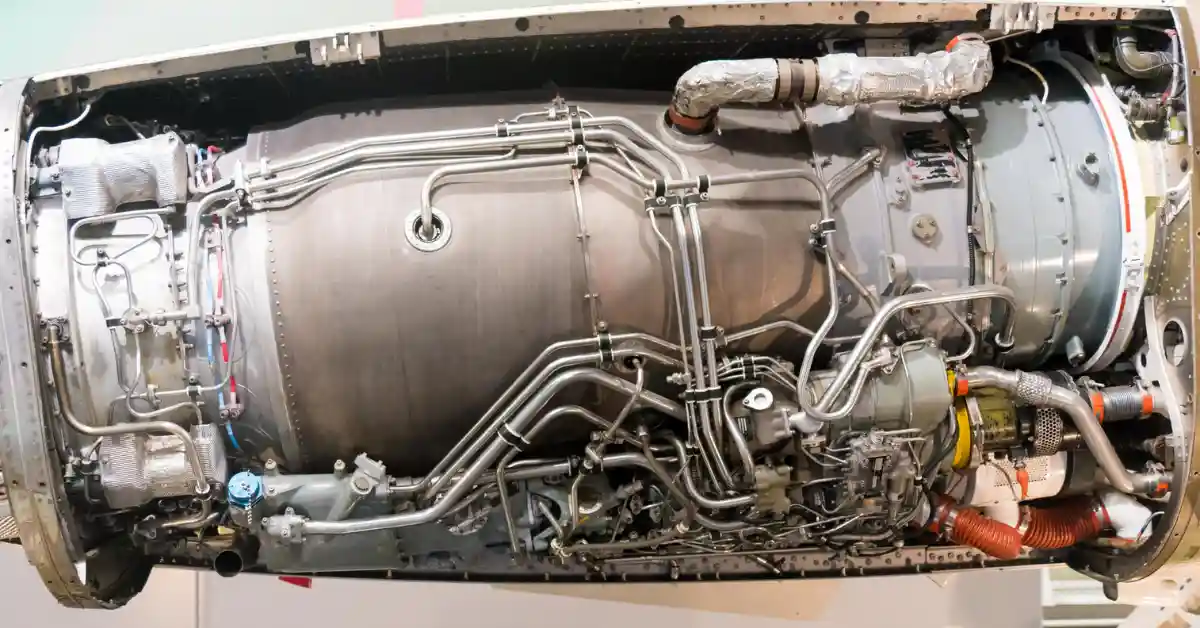

Galvanized steel is made of standard steel, which translates to more strength and impact-resistance, making it ideal for structural applications, bridges, and industrial machinery.

Aluminum, on the other hand, does not have the same structural integrity and strength, but can be alloyed to improve its strength for applications requiring durability without excessive bulk.

Weight

Yes, even in terms of weight, they’re different and there’s a reason why that is.

Aluminum is significantly lighter than galvanized steel. What this does is reduce transportation costs and structural load. This makes it ideal for aerospace, vehicle manufacturing, and roofing, where weight savings matter.

Galvanized steel, on the other hand provides stability and support in heavy-duty applications. They’re substantially heavier and more weighted than aluminum.

Corrosion Resistance

Both materials have a leveled corrosion resistance capability. However, galvanized steel performs better in dry conditions and deteriorates faster in saltwater or acidic environments.

While that’s the situation for galvanized steel, aluminum is highly resistant to corrosion in moisture-rich or marine settings, making it ideal for coastal structures and chemical applications.

Durability

Source: Regan Industrial

We know that galvanized steel is stronger, but is it more durable, though? Galvanized steel is tough but requires regular inspections to ensure the zinc layer remains intact. Once corrosion starts, repairs can be expensive.

Aluminum, while resistant to corrosion, is softer and more prone to dents and scratches, affecting its appearance and structural integrity.

Maintenance

In terms of maintenance, aluminum takes the crown. They require minimal maintenance thanks to its oxide layer that provides natural protection.

Galvanized steel, however, needs regular maintenance to check for coating damage like scratches, dents, and other damages as exposed steel can rust quickly.

Cost and Applications

For the final factors, what’s with the cost of aluminum and galvanized steel? What’s cheaper, more affordable, and what will you go with?

Galvanized steel is more affordable, making it a go-to for construction, fencing, and industrial projects where low and decent pricing matters. It also boasts structural integrity and heavier loads, which make it perfect for the said applications.

Aluminum, while more expensive upfront, offers long-term savings due to its durability and low maintenance, making it ideal for marine, transportation, automotive, and other premium industry applications.

So what takeaways can we have from this in-depth comparison? If you need strength, affordability, and impact resistance, galvanized steel is the better choice.

However, if you prioritize lightweight properties, corrosion resistance, and long-term durability, aluminum is the better option.

What’s Better Galvanized Steel or Aluminum?

Source: Compraco

So, the question still stands. What’s better? Aluminum or galvanized steel?

Here’s a video that differentiates aluminum and galvanized steel in trailers from Move Boat Trailers.

By looking at the detailed and in-depth comparison, it’s clear that the better option will depend on what application you’ll be using it for.

If you need parts and components that have premium structural integrity, strong, and for heavy-duty applications, galvanized steel will be better. But if you need lightweight, low-maintenance, and highly corrosion resistant, aluminum takes the #1 spot.

Get Your Custom Parts from HDC Today!

If there’s one manufacturer you can fully trust with your complete production, there’s no better option than us here at HDC.

We are China’s top manufacturer of aluminum, galvanized steel, copper alloy, titanium alloy, and even plastics!

Our specialization allows us to create custom metal and plastic components for your applications. Just let us know what you need and we’ll make them for you!

Contact us today and we’ll be more than happy to send a free quotation your way!

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!