When choosing a metal component and using it in a strenuous setting, you want to know that this component is able to work under pressure, heat and usage. The flow of grains is significant to the ability of a forged part to deal with these obstacles. A lot of failures occur not due to bad design but due to poor internal grain structure.

With the help of this guide, you will see the proper functioning of grain flow in forging works and the reason why this issue is so critical in 2026.

What is Grain Flow in Forging?

Grain flow in forging is the orientation and alignment of the finely sized metal crystals or grains within a metal piece once forged. All metals possess a natural grain structure, which forms when the metals are cooled and solidified. Upon hammering the metal, the grains are reformed, drawn and made to conform to the part shape.

This is the new grain direction, which contributes to the strength and resistance of the metal. As compared to raw metals where grains are random, the correct grain flow in forging is based on the shape and stress direction of the component. That is one of the reasons why a forged crankshaft or connecting rod is able to withstand more power than a machined or cast one.

How Grain Flow in Forging Works? (Step-by-Step Process)

Heating the Metal for Plastic Deformation

The process of forging begins with heating of the metal to an appropriate temperature. The optimum forging range in every alloy is different. An example of such material is steel, which requires high heat but not melting conditions.

Grain can move without cracking only when there is heat. Metal is not hard and brittle but soft clay at the proper temperature. Grains move against one another and reform.

Defects such as tearing and irregular growth of grains are avoided due to proper heating. One of the most vital processes in the forging process is temperature control.

Applying Pressure and Shaping

After heating, the metal is put into forging machines. Compressive forces are directed by presses or hammers. This force forces metal into the shape that is required.

When force is applied to the metal, the grains become stretched. They are extended with the line of the flow of materials. They do not break but adjust themselves to the new geometry.

Better the grain flow, the stronger the control of the pressure. The forging equipment of 2026 is modern and it can apply force accurately to provide consistent results.

Grain Alignment Along the Part Contour

The best consequence of forging is that it leads to the alignment of grains along the part contour. Grains obey the external path of the shape and the internal path of the stress of the component.

This directional flow of the grain makes the part have better handling of loads. Stress moves in the direction of the grains and not across them.

Due to this congruency, forged parts are much stronger against cracking, bending and fatigue than cast or machined parts.

Types of Forging and Their Impact on Grain Flow

Various processes of forging determine the way metal moves and the orientation of the grains. Type of forging has a direct impact on strength, durability and performance. These differences will make you choose the correct process for your component.

Open Die Forging Grain Flow

Open die forging is between simple or flat dies. When it is being deformed, the metal is not contained completely.

The effect of this technique is that it gives robust and continuous flow of grains with minimal restrictions. Grains stretch automatically along the flow of materials, thereby enhancing internal strength.

Open die is best suited for large, simple components like shafts, rings and cylinders. It has a high mechanical strength and toughness but has a low degree of shape precision. The method is frequently used because it is often selected by engineers who are interested in size and strength but not in detailed geometry.

Closed Die Forging Grain Flow

In closed die forging. Shaped dies are used, which shape the flow of metal. The die is filled with high-pressure metal.

This is done to produce flowing and extremely controlled grains. Grains adhere to the intricate form of the part that enhances load-carrying capacity and fatigue strength.

Closed die forging is used in industries in the production of parts that require strength and accuracy. This controlled grain alignment and uniform quality is of great use in the automotive and industrial parts.

Impression Die Forging and Precision Forging

Even greater control over the grain flow is in impression die forging and precision forging. Such processes direct metal through detailed die patterns of little excess material.

They minimize waste of materials, enhance quality of surfaces, and provide predictable grain orientation. The grain structure is preserved since a reduced amount of machining is required.

These methods are used in aerospace, automotive and medical fields, where performance, reliability and dimensional accuracy are of primary concern.

Directional Grain Flow Explained

Directional grain flow implies that the metal grains follow the direction of the direction that will undergo stress or load on the part. Perfect fit results in even distribution of forces, whereas an imperfect fit leads to concentration of stress and premature failure. Engineers do forging processes to follow directions of maximum load grains.

Examples include:

- Crankshafts that have grains along the shafts and the rods.

- Bend-resistant gears are geared with grains.

Grain flow directions enhance resistance to fatigue which is important when it comes to parts that are subjected to repeated stresses.

Benefits of Grain Flow in Forging

The primary cause of the superiority of forged parts over cast and machined parts is the grain flow. When the alignment of the grains is done properly, several mechanical properties are enhanced simultaneously.

Increased Strength and Toughness

Flowing of forged grains enhances tensile and yield strength. Grains that have their axes oriented in the same direction hold each other together rather than separate.

This one is also a frame that is better at absorbing impact. Consequently, the forged parts do not crack when exposed to sudden shocks.

Improved Fatigue Life

Stress leads to fatigue failure in the long run. Forged grain flow also minimizes the points of crack initiation by removing sharp grain discontinuities.

Consequently, components have a longer lifespan under cyclic loads, as well as retain their performance during their service life.

Better Structural Integrity

Forging eliminates internal porosity and seals up porosity in castings. The metal is solidified into the density and uniformity of the part.

This enhanced integrity enhances trustworthiness in critical processes like aerospace, automobile, and pressure systems.

Enhanced Wear and Impact Resistance

Grain that runs parallel eliminates the wear of the surface since the stress is evenly distributed. The substance is more resistant to abrasion and deformation.

This will increase service life in severe surroundings where components are in a state of friction, impact and extreme conditions.

Grain Flow in Forging vs Other Manufacturing Methods

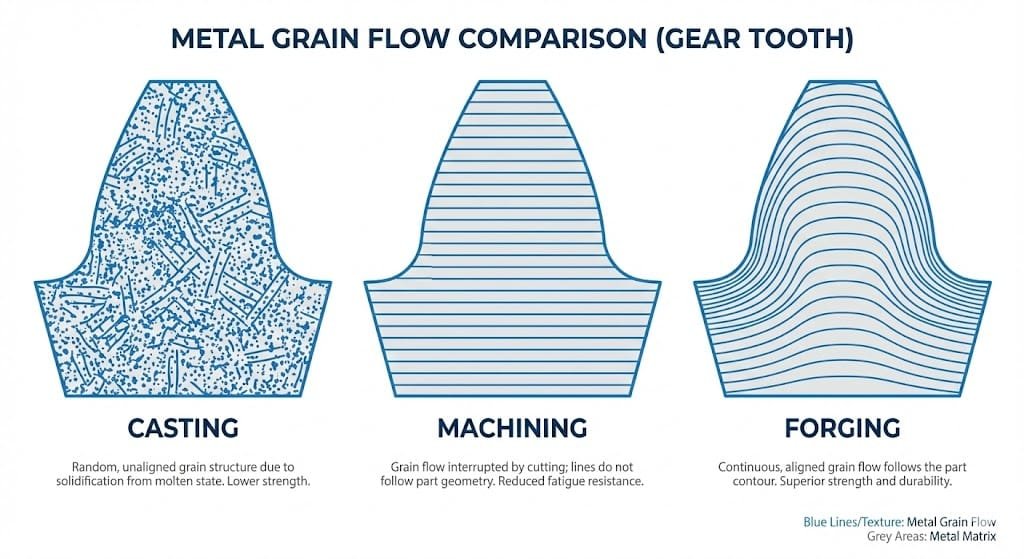

Forged vs Cast Grain Structure

The grains formed during casting are not oriented and this might result in weakness. Grain flow in forging puts the grains in the shape of the part. This makes forged parts stronger, tough and more reliable.

Forged vs Machined Parts

Machined components are cut across grains, making the metal weak. Forging maintains continuity of grain and it works better than machined components in the load. Machining might be cheaper than grain flow in forging cost-wise; however, in performance and longevity there is no comparison.

Comparison Table: Grain Flow in Forging vs Casting vs Machining

| Feature | Forging | Casting | Machining |

| Grain Flow | Aligned with part shape | Random | Cut through grains |

| Strength | High | Moderate | Moderate to low |

| Fatigue Resistance | Excellent | Low | Low |

| Defects | Few | More porosity | Few, but grain interrupted |

| Application | Critical load-bearing parts | Decorative or low stress | Prototype or simple parts |

Real-World Applications of Grain Flow Forging

The theory of grain flow in forging is not only theoretical but it also has a direct effect on the performance of parts in the critical industries. We will consider some of the situations where appropriate alignment of grains will matter.

Automotive Components

Crankshafts, connecting rods and gears are dependent on forged grain flow, as they are durable. Grains that are aligned assist these components to withstand high torque, vibration and recurrent stress. Components do not wear out or break under heavy loads without the appropriate flow of grain. False automotive parts will be longer-lived and will need fewer repairs.

Aerospace and Defense

Turbine parts, landing gear, and structural parts require accurate grain alignment to ensure safety. Directional flow of grain enables these components to withstand extreme forces during takeoff, landing or flight. Forging provides products that are typically vital, in terms of aerospace and defense, to perform well even in severe conditions where the inability to act upon failure is unacceptable.

Oil, Gas and Heavy Machinery

Forged strength is being applied in valves, flanges, pressure vessels, and drilling equipment. The continuous flow of grain avoids cracking, which is caused by high pressure, heat and mechanical abrasion. Correct forging also enhances toughness and fatigue resistance that is essential in components that are used in pipelines, refineries and heavy machinery.

Medical and Industrial Equipment

The orthopedic implants and surgical tools of high stress and precise industrial components are best suited to controlled grain flow. These parts are guaranteed to be strong, reliable and safe to use again and again due to forging. Grain direction minimizes microfractures and provides high performance of the product in severe conditions.

Common Grain Flow Defects and How to Avoid Them

In spite of the right methods of forging, defects may occur when the processes are not observed closely. Knowledge of how a defect is common will assist you in avoiding making the defect.

- Incorrect design of the die will interfere with the grain paths, resulting in weak areas or poor alignment of the grain.

- Misaligned forging temperature ruins the grain structure resulting in cracks or brittle areas.

- Excessive plasticity of grains leads to over-plasticity and decreased fatigue strength.

- Under-forging causes the grains to be out of line and underdeveloped, thereby lowering the mechanical strength.

- Poor Material Selection: There are others that are not effective in forging and with these types of materials, the process of controlling grain flow during the forging process is challenging.

Prevention of Defects: The correct design of the die, the accurate control of temperature, the appropriate pressure of forging and the proper choice of material will guarantee the maximum flow of the grain and the production of high-quality products.

How Engineers Analyze Grain Flow in Forged Parts

There are various techniques of grain flow studies and checks by engineers:

- Micro tech analysis shows macro grains and direction of flow. It assists in detecting imperfections such as laps or imbalance.

- Microstructural analysis entails the use of microscopes to examine grain size, shape, and direction in a fine manner. This would guarantee that the grains have been oriented along the stress paths of the part.

- Simulation and CAD Based Modeling: Current software can be used to model the grain flow in forging and the weak points can also be predicted in advance before forging. The process is even more precise in 2026 with the help of AI assisted simulations.

The combination of these will ensure that the forged parts will be strong, durable, and reliable.

Modern Advancements in Grain Flow Control

The technology of forging keeps on rising. The current improvements in technology render the movement of grains more predictable and efficient.

- Simulations with AI are used to optimize die design, metal flow, deal with errors and enhance strength.

- State-of-the-art die materials will be wear resistant and will exhibit constant outcomes during prolonged production processes.

- The technologies of precision forging make it possible to control the dimensions of parts and the alignment of grains accurately.

- Forging becomes more environmentally friendly with the sustainability improvements that lower material waste and consumption of energy.

These inventions enable the manufacturers to come up with stronger, more reliable and more economical forged elements than ever before.

How to Choose the Right Forging Method for Optional Grain Flow

The correct choice of forging technique is what makes the grains come out correctly to provide maximum strength and performance.

- Part Geometry: Intricate forms might require closed die or precision forging.

- Load and Stress Requirements: Forging of the high-stress parts is best done with the maximum directional grain flow.

- Industry Standards and Certifications: Certified forging processes are frequently mandated in the automotive, aerospace and defense industries.

- Cost vs. Performance Balance: Forging can be seen to be more costly now but less expensive in the form of maintenance and failure costs.

These factors, by taking them into consideration, will make sure the part works optimally during its service life.

Conclusion: Why Grain Flow Defines Forging Quality in 2026

Grain flow in forging is not only a technicality but also the foundation of the strength of parts, fatigue, and reliability. Correct grain orientation enables the metal to effectively manage the stress and extend its life as well as work safely in the harsh environments.

In HDC, we are particularly concerned with the provision of high-quality components in forged form where the grain flow is well controlled to achieve the industry standards. Our advanced simulations and precision forging methods are to guarantee that each of the parts is at its best performance. When in need of increasing the strength and durability of the metal parts, you have the best option to consider: proper forging with the knowledge of HDC.

Contect us today to find out how our parts, which are optimized to the flow of grain, can satisfy you.

FAQs

Why is Grain Flow important in forging?

The grain flow regulates the strength, fatigue life and durability.

Can grain flow be controlled completely?

It can be controlled with ease and accuracy with proper die design and process control.

How do you check grain flow direction?

Etching as well as microscopy and simulation tools is used by engineers.

Does grain flow affect corrosion resistance?

Yes, with improved grain orientation, there will be fewer crack paths on which corrosion is initiated.

Which metals benefit most from grain flow forging?

There are significant benefits of steel, aluminum, titanium and nickel alloys.

Is grain flow important for lightweight designs?

Yes, it is permissible for thinner parts without loss of strength.