Guide to Control Arm in Automobile Suspension System

- By: HDCMFG

A steady and smooth ride matters more than any shiny feature in a car. That’s why many people want to know what a control arm is and what it actually does. I will explain this with simple logic: You and I both know that no car stays perfectly steady on every road. But a good suspension system, supported by strong control arms, keeps your ride smooth and stable.

In this guide, you will learn what a control arm means, how this works and the different types.

What is a Control Arm

You may know the control arm by other names like an A-arm or wishbone. This is basically a hinged link in your car’s suspension. One end attaches to the chassis and the other end to the wheel hub. The arm itself is a strong metal lever. You can think of it as the piece that holds your wheel to the car frame. This arm allows the wheel to move vertically with bumps while keeping it properly aligned.

Components attached to the Control Arm

A typical control arm has two main components at its ends: bushings and a ball joint. The inner end connects to the frame using flexible bushings (most usually rubber). That lets the arm pivot up and down. The outer end attaches to the wheel knuckle via a ball joint. You can take the ball joint as a steel ball in a socket that allows the wheel to turn and move vertically.

The bushings and the ball joint together allow smooth plus controlled wheel movement while absorbing shocks and vibrations.

Control Arms made of

Modern control arms are made of sturdy materials. You will mostly find them made of stamped steel or cast iron or cast aluminum.

- Though steel arms are strong and cheap. But they can rust over time.

- Cast iron is heavier. But they are very durable, so mostly used in trucks.

- Aluminum arms are lighter and resist corrosion. But they can wear faster on impact.

Thus, each material choice trades off weight, cost and strength according to the vehicle’s needs.

Types of Control Arms

The design of your car’s suspension tells what type and how many control arms it uses.

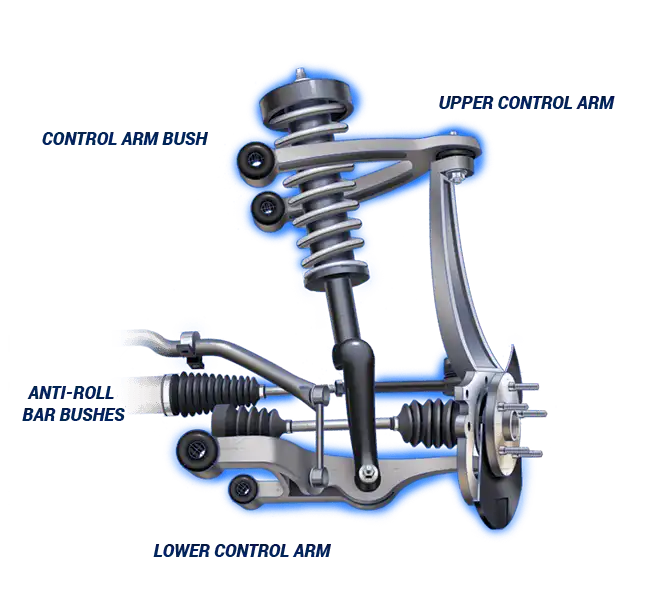

Control Arms in Double Wishbone Suspension

Double wishbone suspension means you have two control arms at each wheel. An upper arm and a lower arm. They are shaped like wishbones or the letter “A”. Each arm attaches at two points on the chassis to form a triangle.

You might hear the term double A-arms for this setup. With upper and lower arms, you can precisely control the wheel’s camber, caster and toe angles as it moves. This gives very stable alignment and handling. For example, as the suspension moves, the design helps maintain the right tilt (camber) and steering geometry. That is why sports and high performance cars often use double wishbone suspensions.

Both control arms in a double wishbone system are usually forged or cast pieces made of steel or aluminum. Also, they can be A-shaped or L-shaped. The upper arm is mostly shorter to induce negative camber during turns. This improves grip. The arms are very strong and provide good wheel stability. Because of all this, a double wishbone setup can be heavier and more expensive. But it offers excellent handling and alignment control compared to simpler designs.

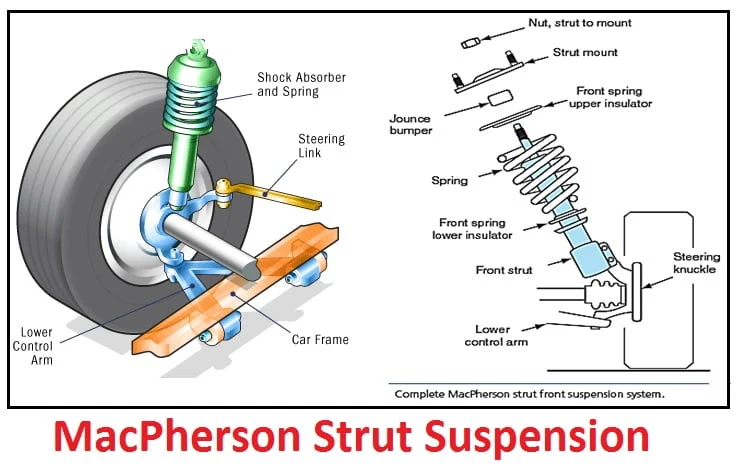

Control Arms in MacPherson Strut Suspension

Many modern cars use the MacPherson strut suspension. In this design, each wheel has only a single lower control arm . The “upper arm” is replaced by the strut, which combines the shock absorber and coil spring into one. But you still have one strong control arm below the wheel that links it to the car’s frame.

This lower arm is usually A-shaped or L-shaped. This arm carries the wheel and transmits forces while the strut handles vertical loads from above. Also, MacPherson struts are simple, light and cheap to produce. That’s why you see them on many family cars and economy models. They save space and cost by not needing two arms. However, with only one arm, you will get less adjustability in camber and toe.

Control Arms in Multi-link Suspension

Multi-link suspension breaks down the old double wishbone into several separate links. Instead of one upper and one lower arm, the number of arms depends on design. You will have three, four or even five smaller arms per wheel. Each link basically handles a specific motion. For example, one link may control fore-aft movement (a trailing arm), another may control lateral location (a lateral link), and others manage toe or camber changes.

In fact, a multi-link system can be viewed in three planes. One pair of links (in top view) adjusts toe or lateral movement, another pair (in front view) controls camber changes and one link (side view) handles acceleration/braking loads. Due to this, multi-link designs can tune toe and camber independently. Also, a common setup can be a 5-link rear suspension. Like, two lateral links, two trailing links and one toe or camber arm per wheel.

The advantage is that you can adjust one geometry parameter at a time without affecting others. That means better ride and handling in one design. But, Multi-link suspensions are more complex and costly. So, you will mostly see them in luxury and performance cars and some SUVs.

Each link connects via bushings or ball joints, just like regular control arms. For example, trailing arms are used on solid axles and if a car has independent rear suspension, it often uses its own set of arms or links as part of a multi-link design.

Function of the Control Arm

You might think, what exactly does the control arm do for you? Its main job is to control wheel motion and alignment as you drive. For example, when your car hits a bump or dip, this control arm allows the wheel to move up and down. Actually the rubber bushings flex at the end of the chassis allow that pivot. This clearly means the wheel would have no guide for vertical motion without the control arm.

Moreover, the control arm keeps the wheel aligned. This arm holds the wheel at the correct angle relative to the car body. That means it controls camber (tilt) and toe (direction) so the tire touches the road evenly. And of course, all of this is very important for getting a smooth ride and being able to steer the thing with any precision at all.

The control arm also helps in absorbing shocks and vibration. It provides a point for the spring and shock to act. Usually a heavy coil spring is present on top of or just above the control arm. When the wheel rises on a bump, this control arm swings and compresses the spring. And the shock absorber then dampens the motion. This setup cushions you from road harshness and gives a smoother ride.

Furthermore, the control arm is a mounting point for other parts. For example, a stabilizer bar link that attaches to the control arm and twists when you turn the corner. This helps in stopping the car from rolling over. Also, the control arm itself often has adjustable points on the frame. Mechanics can tweak these to fine tune wheel alignment after replacing parts.

How the Control Arm works

First, note that the control arm pivots on bushings. Those rubber or polyurethane bushings at the frame connection allow the arm swing up and down as the wheel moves. They also absorb shocks and reduce vibration before it reaches the car body. When the road rises under the tire, the arm’s inner end simply pivots in those bushings to move the wheel vertically.

The other key part is the ball joint at the wheel end. This ball joint allows steering and vertical motion at once. You can take it as a universal joint. Like, you have a steel ball that fits into a socket. This basically allows the wheel knuckle to rotate (to steer left/right) while also letting it move up/down on bumps. For example, when you turn the wheel, this arm stays connected by that ball joint and guides the wheel around its pivot.

Also, the control arm works directly with your springs and shocks. For example, in a front suspension, a heavy coil spring is mostly fixed between the arm and the frame. When your car hits a bump, the control arm pushes on the spring. The spring compresses to absorb the energy. A shock absorber, which may be attached to the arm or strut, then slows down the bounce. This is why a worn ball joint or broken arm can make the ride feel rough or clunky.

Because the control arm determines wheel position, it affects alignment. Many control arms include adjustable links or shims at the frame end. For example, if a new arm changes the camber angle, the adjuster allows the tech to realign the wheels so you drive straight.

The control arm sometimes has a link for the sway bar. In a turn, as the body rolls to one side, this sway bar pushes on the control arm of that side and pulls the opposite side’s arm. This action helps level the car.

Conclusion

A control arm is a small part of the suspension system with an important role. It connects the wheel to the car’s frame and helps the suspension work properly. The control arm comes in different types for different suspensions. This is very essential for smooth driving, proper wheel movement and stable handling.

You can check out our high quality control arms made with closed-die forging for better performance and durability.

FAQs

What are the signs of a bad control arm?

You may hear clunking or knocking sounds when your car goes over bumps. Or your car may swerve or pull to one side or the steering may feel loose. Also, you may see uneven tire wear or extra vibration in the steering wheel. These signs basically mean the control arm is worn.

How many control arms are in a car?

Many cars have mostly two main control arms on the front axle, one on each side. Some cars (specially those with independent rear suspension or heavy duty) have control arms in the rear too. In those cases you will have four or more total control arms.

Is a control arm repairable?

You basically need to replace the control arm instead of repairing it. If only a bushing or ball joint is bad, a shop may press out that component. But in many cars the ball joint is sealed. So you have to swap in a new arm.

How much does it cost to fix a control arm?

Control arm assemblies generally cost around $50–$250 each. But this depends on material and vehicle. Also, labor and alignment will add to the bill. Thus, in total, expect a range from about $100 up to a few hundred dollars per arm. Also, it depends on your car and shop rates.

How do you test a control arm?

For this, raise the car and try to move the wheel and arm by hand. If you use a pry bar near the bushing and the arm moves significantly (more than a few millimeters). Then the bushing is more likely worn. Similarly, try moving the wheel side to side. Any looseness or clunk at the wheel end usually means a worn ball joint.

What is another name for a control arm?

The control arm is sometimes called an A-arm or wishbone. In rear suspensions with solid axles, similar links are called trailing arms. But on many modern cars, “control arm” or “A-arm” are the usual terms.

Are ball joints and control arms the same thing?

No, the ball joint is a component attached to the control arm. The ball joint is a swivel where the arm attaches to the wheel knuckle. So the arm includes bushings and usually a ball joint. But the joint itself is just one part.

Do you need an alignment after replacing a lower control arm?

Yes. Because changing a control arm often changes the camber or toe angles. Thus, the mechanic needs to adjust the suspension alignment after installation.

How many hours does it take to replace control arms?

It depends on the car. But mostly plan about 1-2 hours of labor per control arm. Some vehicles are easier and some harder to work on. Don’t forget that an alignment is usually needed afterward, which can add extra time.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!