In 3D printing, PETG vs. PLA is one of the more common filament comparisons because of their features. So, in this article, we’ll be comparing PETG and PLA side-by-side to help you gain a better view of what they are individually, and what they can put to the table.

What is PETG?

PETG is an abbreviation for Polyethylene Terephthalate Glycol, which is a thermoplastic polyester that’s used in 3D printing and manufacturing.

In breaking it down, the PET is the plastic often found in bottles and food products. The G, however, is the component that adds durability and strength and contributes to the resistance of the product.

Businesses and companies use PETG because of the benefits it offer–flexibility and durability, among others.

What is PLA?

Polylactic acid (PLA), on the other hand, is another type of synthetic thermoplastic polymer made from plant-based materials. It is a renewable and sustainable product.

PLA is often derived from carbohydrate fermentation of products such as wheat, potatoes, cassava, corn, etc.

FUN FACT: PLA is the second-most produced bioplastic. It has almost identical characteristics and properties as polypropylene (PP), polyethylene (PE) and polystyrene (PS).

PETG vs. PLA: Comparing the Two Filaments

In the world of 3D printing, PETG and PLA are two of the most popular filaments, each offering unique benefits. Your unique needs—such as strength, heat resistance, and printing ease—will determine which material is best for you.

To help you make the best decision, let’s take a look at the different characteristics that distinguish these two products.

Strength and Durability

PETG is clearly the better choice in terms of durability. It’s perfect for outdoor and functional prints because it is more resistant to impact, UV rays, and chemical deterioration than PLA.

PLA, on the other hand, is adequate for prototypes or decorative items that won’t be subjected to mechanical stress, despite its lower durability.

NOTE: Unlike PLA, which can eventually become brittle, PETG’s flexibility lowers the chance of cracking.

Heat Resistance

PETG outperforms PLA in terms of heat and temperature resistance. PETG can withstand temperatures up to 80°C or higher, making it suitable for parts exposed to heat, such as car mounts or machine components.

In contrast, PLA softens at around 50–60°C, limiting its use to cooler environments or static applications. This difference makes PETG a better choice for demanding environments, while PLA works well for general use.

Chemical Resistance

Let’s not forget an important factor in materials like this–chemical resistance. When it comes to chemical resistance, PETG is superior to PLA.

It is a better option for industrial components, medical equipment, and containers because it can tolerate exposure to acids, solvents, and oils without deteriorating.

PLA’s suitability for demanding environments is limited because, despite its resistance to certain chemicals, it degrades easily when exposed to moisture or aggressive substances.

Flexibility and Impact Resistance

Flexibility-wise, PETG can handle stress better. Furthermore, it also provides superior impact resistance. This characteristic makes it appropriate for components that need to be durable, like bottles or protective casings.

In contrast, PLA is more brittle and rigid, which can cause it to break or crack in similar circumstances.

Food Safety

When it comes to food safety, you don’t have to worry, both are rated to be safe and secure in handling food. Both PETG and PLA are considered food-safe when manufactured without additives, but PETG is more durable and resistant to contamination.

It’s often preferred for reusable items like water bottles and food storage containers, while PLA is more common in disposable utensils and biodegradable packaging.

Sustainability

PLA is biodegradable and derived from renewable resources like cornstarch or sugarcane, making it the eco-friendly choice for sustainable manufacturing. PETG, while recyclable, is petroleum-based and less environmentally friendly.

For applications with sustainability goals, PLA is often the preferred option.

Cost and Availability

And last but most definitely not least is price and availability. Let’s be real – price is one of the most impacting factors in choosing a product, and in plastic materials, it’s no different.

PLA is generally more cost-effective and widely available, especially for small-scale production or prototyping. PETG tends to be slightly more expensive due to its enhanced properties, but its durability often justifies the higher cost for long-term use.

These are a few of the important factors you need to consider when choosing between PETG and PLA. You need to make sure that these characteristics and properties are aligned to the purpose you want. So, triple-check and ensure that you’re choosing them in the best way you can.

Will PETG Melt in the Sun?

No, PETG melting when exposed under the sun for long is untrue. PETG is naturally UV-resistant to some degree, but it’s not indestructible. The melting point of PETG sits at about 240 to 260 °C, which is around 500 °F.

However, long exposures under the sun can deform PETG products, especially 3D-printed PETG that are typically thin and low in volume.

What is the Lifespan of PETG?

The typical shelf life of PETG products and filaments last about 1 to 2 years, the same as PLA. ABS has the fastest and shortest shelf life, sitting at about 6 to 8 months maximum.

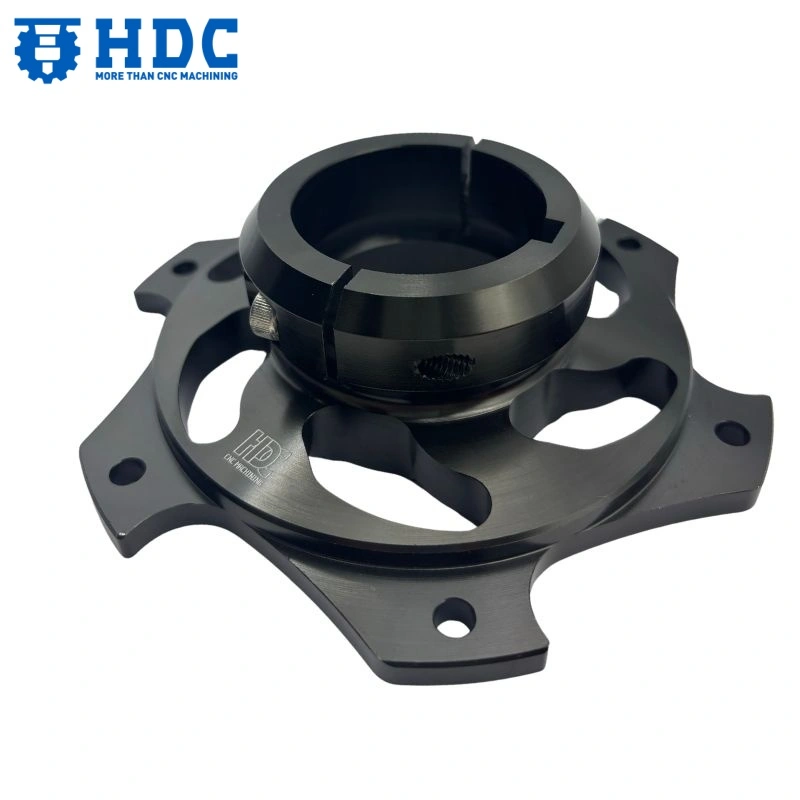

Why HDC Manufacturing is the Best For PETG and/or PLA?

Now that you have the best of ideas for PETG vs. PLA, it’s equally important to know and be aware of which manufacturer or supplier to go with.

Here in China, HDC Manufacturing has been the best, the most reliable, and the most banked on when it comes to different components and materials. Plastics to metals, we got what you’re looking for! Just let us know what you need and we’ll be more than happy to help you out with it!

We’re considered to be the country’s best one-stop solution for metals and plastics. Our services are scattered from the automotive and aerospace industries to medical, construction, and even transportation.

For high-quality and premium plastic materials, you can place your complete trust in us here at HDC Manufacturing. Hundreds of businesses and organizations have worked with us and gave us the thumbs up–we’re sure you will, too!

Contact us today and experience world-class quality services!