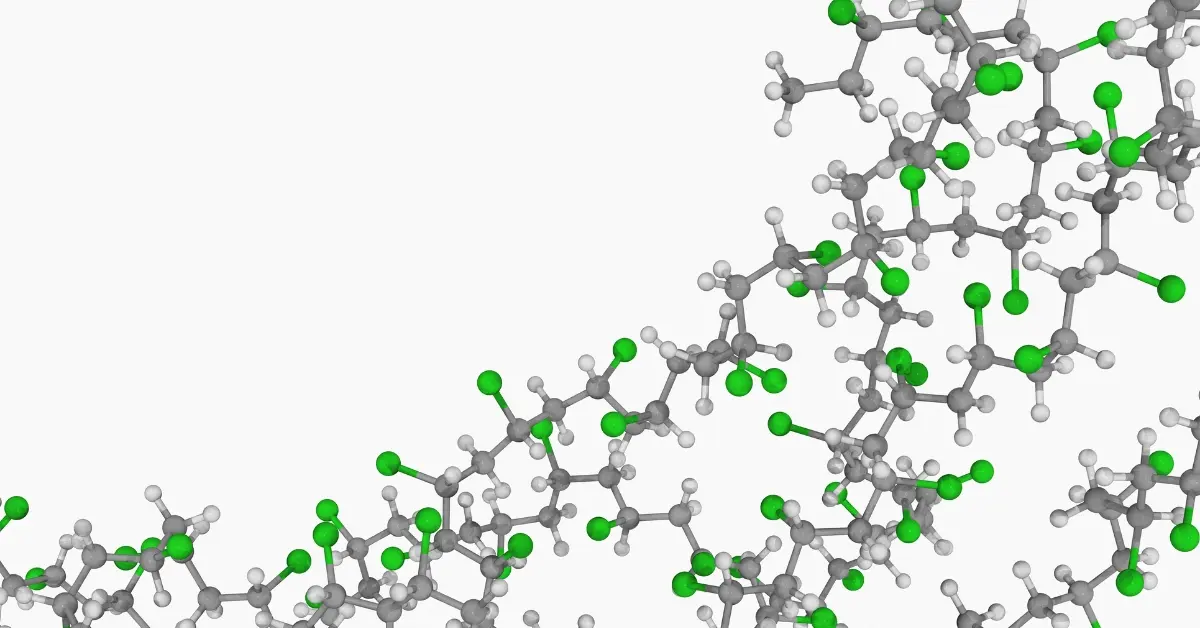

Polyvinyl chloride, commonly known as PVC plastic, is one of the most widely used synthetic plastics in the world. Its versatility and resilience make it an essential material across various industries, from construction to electronics. This article dives deep into several key aspects about PVCs, including what PVC plastic is? its unique properties, how it compares with other materials like ABS and CPVC, and its applications in everyday products.

What is PVC?

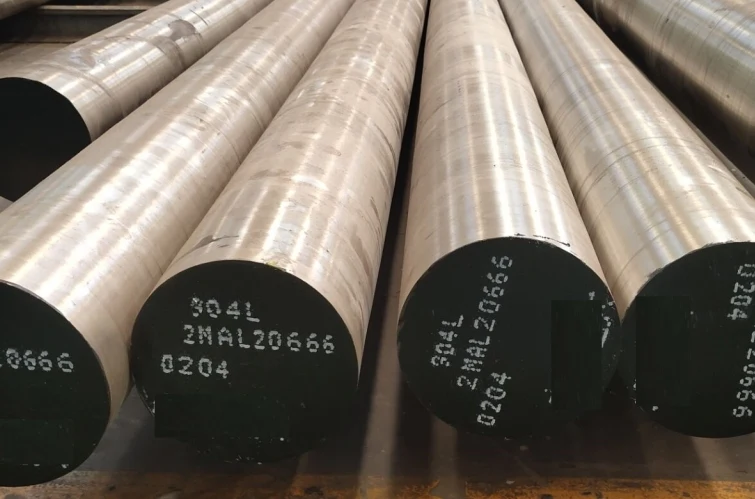

PVC is a synthetic plastic polymer made from vinyl chloride monomer. It comes in two main types: rigid PVC and flexible PVC. Rigid PVC is commonly used for construction applications like pipes, window frames, and siding. Meanwhile, flexible PVC is made softer by adding plasticizers, making it ideal for applications such as wiring insulation and flooring.

Types of PVC Material

- Rigid PVC: Primarily used in construction for items such as pipes and window frames.

- Flexible PVC: Softened by adding plasticizers, used for flexible applications like cables, hoses, and flooring.

- CPVC (Chlorinated PVC): Similar to PVC but more heat-resistant, often used in hot water systems.

PVC plastic is characterized by its strength, durability, and chemical resistance, making it a favored choice for many applications.

Key Properties of PVC

- PVC Density: PVC has a density of approximately 1.38 g/cm³, making it a relatively lightweight yet durable material.

- PVC Melting Point: PVC’s melting point ranges between 160-210°C, depending on its formulation. This heat tolerance allows it to withstand high temperatures in various industrial and transport applications.

- Weather and Chemical Resistance: PVC is known for its resistance to environmental degradation, weather conditions, humidity and chemicals, which enhances its lifespan in outdoor settings.

- Electrical Insulation: Due to its high dielectric strength, PVC is commonly used in electrical conduit and insulation applications.

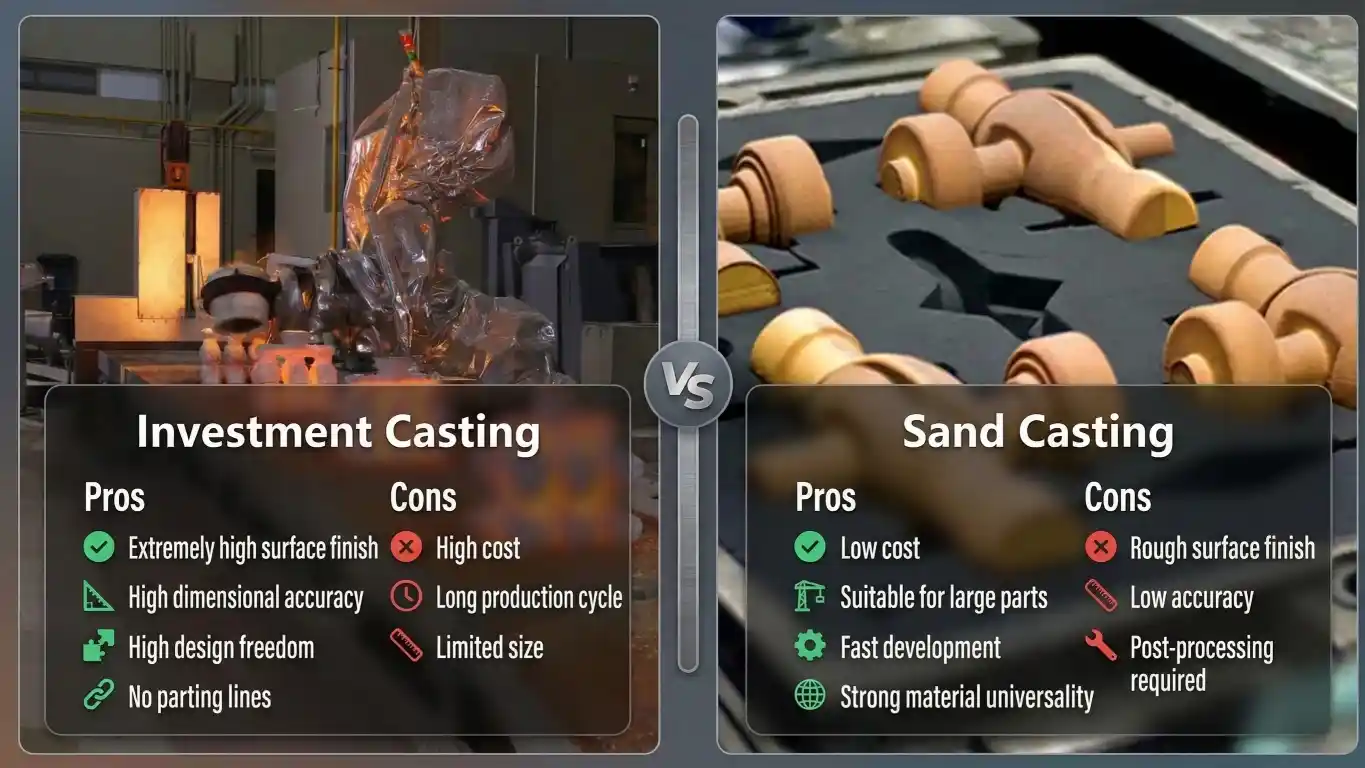

PVC Processing Methods at HDC Manufacturing

HDC Manufacturing processes PVC plastic using state-of-the-art technology, ensuring that each product meets the highest quality standards. Here’s how HDC Manufacturing’s advanced techniques and experienced workforce contribute to premium PVC plastic production:

CNC Machining

HDC Manufacturing employs cutting-edge CNC machining technology, which allows for precision and consistency in crafting complex and detailed PVC parts. This advanced machinery, guided by skilled operators and engineers, can produce intricate shapes and designs with exceptional accuracy, ensuring every piece meets exact specifications and standards. With the combination of technology and expertise, HDC can fulfill even the most demanding project requirements, creating durable and reliable components for diverse applications.

Injection Molding

For high-volume production, HDC Manufacturing utilizes state-of-the-art injection molding technology. This process is ideal for efficiently mass-producing PVC parts with uniformity across each batch. HDC Manufacturing’s experienced team works closely with the latest injection molding machinery to fine-tune every step of the production process, ensuring that each PVC component is consistent, resilient, and ready for immediate use in its application. This combination of advanced technology and skilled personnel results in high-quality PVC products that meet rigorous industry standards.

Together, HDC Manufacturing’s CNC machining and injection molding capabilities, backed by a dedicated, expert workforce, set a high benchmark in PVC plastic production. This commitment to excellence enables HDC Manufacturing to deliver PVC products that are not only precise but also durable and dependable across various industries.

These methods contribute to PVC’s versatility, allowing it to be shaped into various forms, including PVC sheet, pipe fittings, and roofing materials.

Uses of PVC

PVC’s adaptability has led to its use in diverse industries, including:

- Construction: PVC is used for windows, and door profiles due to its weather resistance and durability.

- Plumbing: PVC pipe and PVC pipe fittingsare essential in plumbing systems due to their resistance to corrosion.

- Electrical Applications: PVC serves as an insulator in PVC electrical conduits, protecting wires and cables.

- Roofing: PVC sheets are often used in roofing applications due to their durability, weather resistance, and lightweight nature.

- Healthcare: Flexible PVC is used in medical tubing, blood bags, and IV containers.

Is PVC Safe?

PVC has been the subject of extensive research concerning its safety. While it has numerous benefits, there are environmental and health concerns associated with its production, use, and disposal.

- Production Concerns: The manufacturing process of PVC involves the use of chlorine, which can produce toxic byproducts. Media outlets and activists have time and again raised concerns about the impact of PVC production on the environment toxicity. Therefore, it’s essential to handle PVC safely, especially during disposal.

- Recyclability: PVC is recyclable, but recycling rates remain low due to the complexities involved in processing PVC waste. Specialized recycling facilities are required to break down and reuse PVC material.

- Plasticizers: Some flexible PVC products contain plasticizers, which have been scrutinized for potential health risks, particularly phthalates.

Despite these concerns, PVC is generally considered safe for many applications when handled and disposed of responsibly.

Environmental Impact and Recycling of PVC

PVC’s environmental impact remains a topic of discussion. Its non-biodegradability and potential to release toxic chemicals when burned present challenges for sustainability. However, recycling PVC plastic can reduce waste, though the process is complex. Innovations in recycling and disposal methods are helping to address these concerns, and some manufacturers are investing in eco-friendly PVC production.

HDC Manufacturing takes the safety and environmental impact of PVC production very seriously, adhering strictly to rigorous safety protocols and sustainability standards. Committed to responsible production, HDC Manufacturing ensures that all stages of PVC manufacturing—from sourcing raw materials to final product disposal—are handled in compliance with environmental regulations and safety guidelines. By investing in specialized recycling processes, minimizing harmful byproducts, and using safe, non-toxic alternatives to conventional plasticizers wherever possible, HDC Manufacturing aligns its operations with sustainable practices. This commitment reflects HDC Manufacturing’s dedication to providing high-quality, safe PVC products while reducing its ecological footprint and supporting a more sustainable future.

Comparison of PVC with Other Materials

PVC is often compared to other plastics like ABS and CPVC. Here’s how it stacks up against these materials:

| Property | PVC | ABS | CPVC | Polypropylene |

|---|---|---|---|---|

| Strength | Durable but less impact-resistant | High impact-resistance, ideal for tough uses | Similar to PVC | Moderate impact resistance |

| Cost | Generally affordable | More expensive than PVC | More expensive than PVC | More costly than PVC |

| Flexibility | Flexible, especially in plasticized form | More rigid | Similar to PVC | Less flexible than PVC |

| Temperature Resistance | Moderate temperature tolerance | Handles slightly higher temperatures | Can withstand higher temperatures (up to 200°F) | Limited temperature tolerance |

| Chemical Resistance | Moderate | Moderate | High resistance to corrosive substances | Superior chemical resistance |

| Ideal Applications | General use, budget-conscious projects | High-impact needs | High-temperature plumbing, industrial uses | Chemical-resistant applications |

Why is PVC So Popular?

PVC is widely used because of its adaptability, durability, and affordability. In construction, for example, PVC’s weather-resistant properties and low maintenance requirements make it a favored choice for PVC roofing and siding. Additionally, its insulating properties are invaluable for PVC electrical conduit applications. However, in addition to all the features, the cost-effectiveness of PVC makes it one of the most popular plastics.

Conclusion

PVC plastic continues to be an integral part of our daily lives due to its diverse applications and versatile properties. From PVC pipe fittings in plumbing to PVC sheet in roofing, its affordability and durability make it a preferred choice in various sectors. While there are environmental and safety concerns related to PVC, responsible production, use, and recycling practices can help mitigate these issues.