Understanding Steel Wheel Spacers: Benefits, Types, and Installation

Explore the world of steel wheel spacers, including their benefits, types, and materials. Learn how to select the right size, install them properly, and maintain their performance for improved vehicle stability and handling.

What Are Steel Wheel Spacers

Wheel spacers are essentially metal shims that fit over the vehicle’s existing studs, pushing the wheel away from the hub. Steel wheel spacers, in particular, are known for their durability and strength. They come in various sizes and thicknesses, allowing for customization based on individual preferences and vehicle requirements.

Benefits of Using Steel Wheel Adapters

Improved Vehicle Stability:

One of the primary benefits of steel wheel spacers is the enhancement of vehicle stability. By widening the track width, spacers lower the vehicle’s center of gravity, reducing the risk of rollovers and improving overall stability, especially during sharp turns.

Enhanced Handling and Performance:

Wheel spacers can significantly impact a vehicle’s handling and performance. The increased track width provides better traction and cornering capabilities, resulting in a smoother and more controlled driving experience.

Increased Tire Clearance:

The wheel Spacer provides extra distance between the vehicle’s body or suspension components and the wheel. This added clearance is especially advantageous for individuals seeking to mount larger tires or aftermarket wheels, effectively preventing any potential rubbing or interference problems.

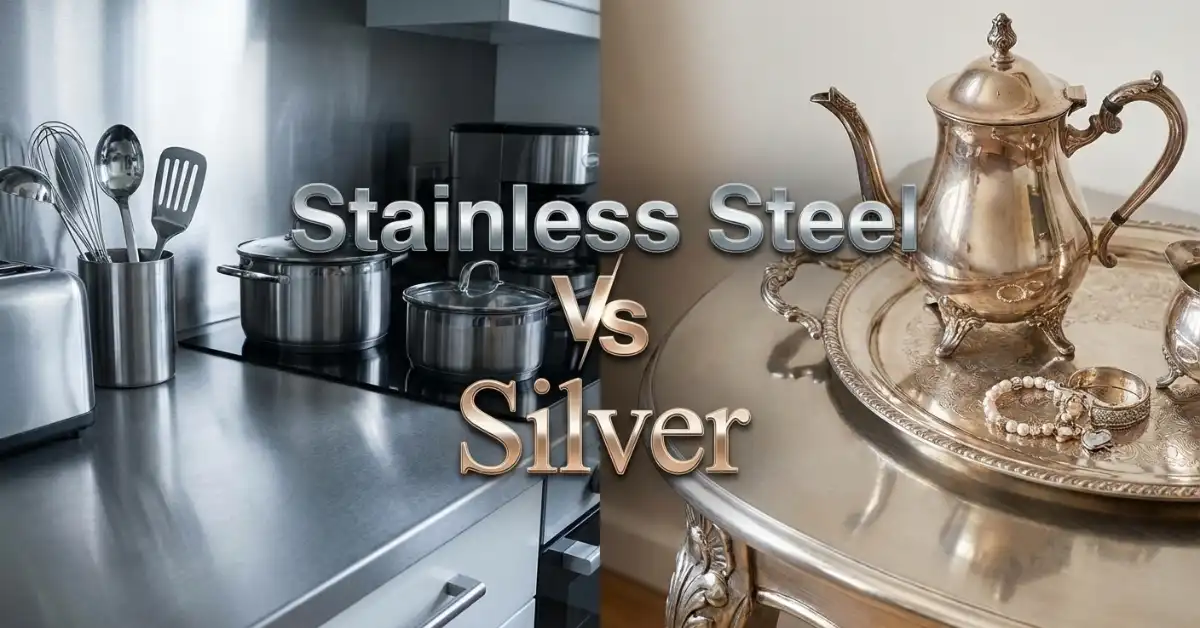

Comparing Steel Wheel Spacers to Other Materials

While steel wheel spacers have their advantages, it’s essential to consider other materials and their pros and cons.

Pros and Cons of Steel Spacers

- Pros:Durable, strong, and resistant to deformation under heavy loads.

- Cons:Heavier than aluminum, potentially impacting fuel efficiency.

Choosing the Right Material

- Aluminum spacers:Lightweight and corrosion-resistant, ideal for those looking to reduce unsprung weight.

- Composite spacers:Made from a mix of materials, offering a balance between strength and weight.

Types of Steel Wheel Spacers

- Hub-Centric:These Spacers have a center bore that matches the hub diameter of the vehicle. This ensures that the load is primarily carried by the hub, reducing stress on the bolts.

- Lug-Centric:Lug-centric Spacers rely on the lug nuts or bolts to center the wheel. The center bore may not match the hub diameter, and the load is distributed through the lug nuts.

Types of Steel Used for Wheel Spacers

- Carbon Steel:

- Alloy Steel:

- Stainless Steel:

Choose the Right Size and Type

- Vehicle make and model:Different vehicles have varying stud patterns and hub sizes, so it’s essential to choose spacers that match your vehicle’s specifications.

- Intended use:Consider whether you’re looking to improve performance, achieve a specific aesthetic, or both, as this will influence the spacer size and type.

Installation Process

- Gather the necessary tools:Before starting the installation, make sure you have the right tools, including a torque wrench, jack stands, and a lug wrench.

- Lift the vehicle:Use a jack to lift the vehicle off the ground, and secure it with jack stands for added safety.

- Remove the wheels:Use a lug wrench to remove the wheels and expose the existing studs.

- Install the spacers:Place the steel wheel spacers over the existing studs, ensuring a snug fit.

- Secure the wheels:Put the wheels back on, tightening the lug nuts with a torque wrench to the manufacturer’s specifications.

- Final inspection:Lower the vehicle slowly to the ground, carefully inspecting the bolts on each tire to confirm that there is no friction between the tires and the body in the loaded state, ensuring proper installation.

Maintenance Tips

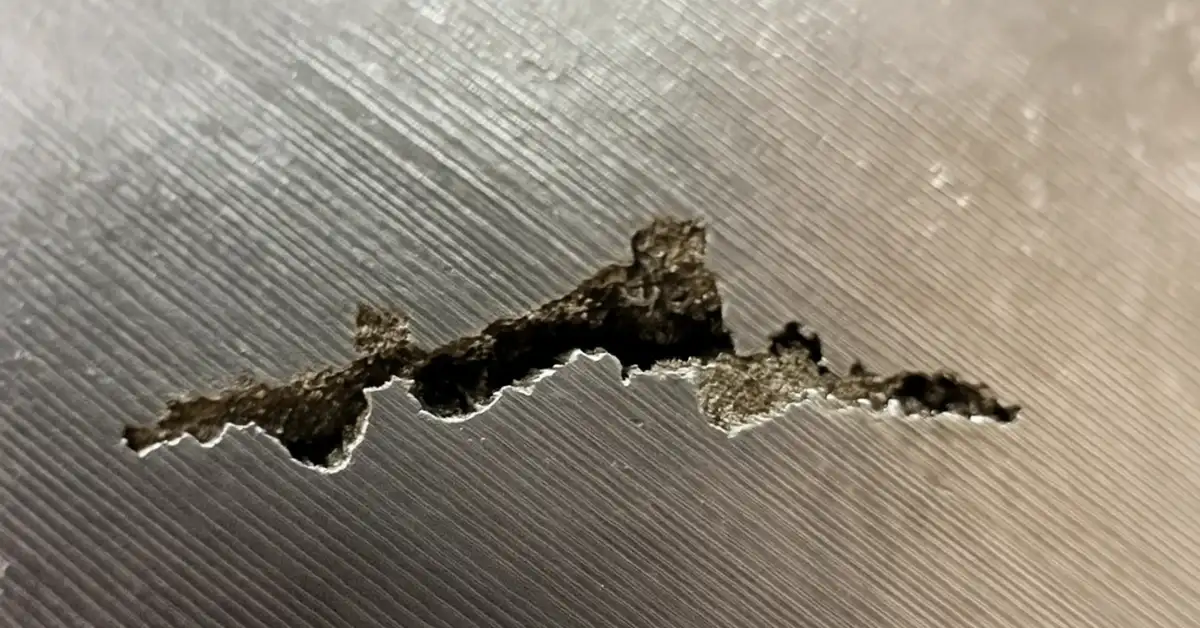

- Regular inspection: Examine for wear or corrosion, ensuring the proper positioning of the wheel spacers.

- Cleaning:Keep the wheel spacers clean from dirt, debris, and brake dust to prevent interference with the proper functioning of the components.

- Replacement:If any issues are detected during inspection, promptly replace the wheel spacers to avoid potential safety hazards.

How to Custom Steel Wheel Spacers

- Research and Choose a Reputable Manufacturer:

- Specify Your Requirements:

- Request a Quote:

- Provide Vehicle Details:

- Review Design and Material Options:

- Confirm Production and Delivery Times:

- Place the Order:

- Follow Up and Inspect:

Conclusion

Steel wheel spacers offer a versatile solution for those looking to enhance the performance and appearance of their vehicles. From improved stability to customizable aesthetics, these accessories have proven their worth in the automotive world. By understanding the installation process, choosing the right size, and addressing concerns, users can experience the full benefits of steel wheel spacers.