The Edge of CNC Racing Parts in High-Performance Motorsports

This comprehensive guide explores the pivotal role of CNC racing parts in motorsports, detailing how they enhance vehicle performance and reliability. From the intricate processes involved in CNC machining to the wide variety of materials used, learn why these parts are crucial for racing. Dive into the benefits and challenges of using CNC technology in the production of racing components and discover how HDC Manufacturing excels in creating top-tier CNC racing parts for various motor sports applications.

Understanding CNC Racing Parts

CNC racing parts is such a vague term, as it can mean parts for automotive vehicles (cars), motorcycles, and bikes. Nevertheless, to help you understand it more and better, CNC racing parts are parts and/or components of vehicles.

These are important factors to consider because, without these parts and components, a vehicle would not be complete and could not be eligible to be used in any type of sport (racing).

Racing Parts Can Be Produced by CNC Machines

Here at HDC Manufacturing, we’ve been able to produce a heap of racing parts via our CNC machines and manufacturing procedures. Our skills and expertise have led us to produce the best and highest quality of CNC racing motorcycle parts, CNC racing car parts, bike parts, as well as CNC sprockets, car shift knob adapters, and many more!These are our main things, though. Other than these, you can get a ton of other racing parts and components, too, such as:

Here at HDC Manufacturing, we’ve been able to produce a heap of racing parts via our CNC machines and manufacturing procedures. Our skills and expertise have led us to produce the best and highest quality of CNC racing motorcycle parts, CNC racing car parts, bike parts, as well as CNC sprockets, car shift knob adapters, and many more!These are our main things, though. Other than these, you can get a ton of other racing parts and components, too, such as:- Bushings

- Exhaust parts

- Racing Seats

- Suspension components

- Valve retainers

- Fluid system components

- Housings

- And many others more!

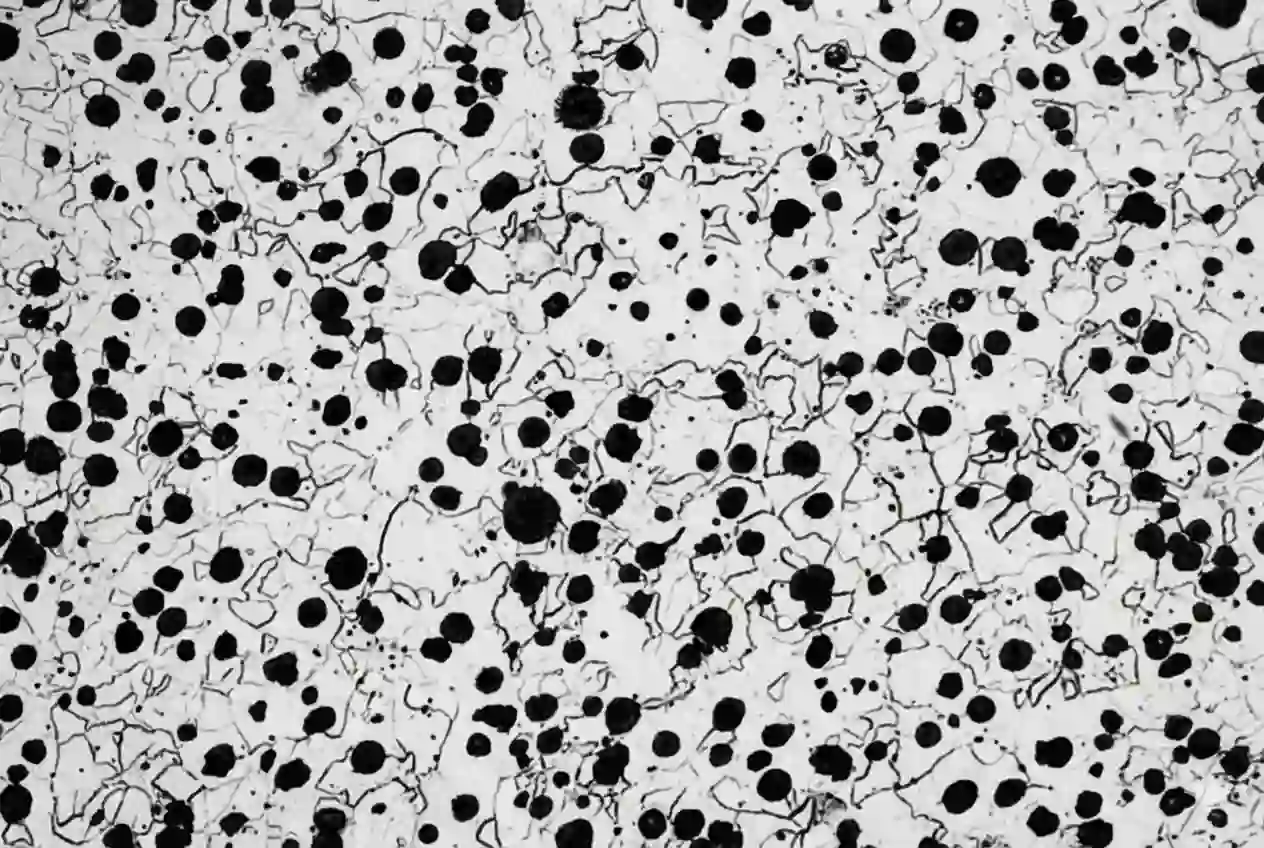

CNC Techniques for Manufacturing Racing Parts

CNC (Computer Numerical Control) techniques are essential to the production of racing parts that require high precision and customization. The technologies include milling turning, drilling tapping and engraving that facilitate the manufacture of quality components with excellent high performance in racing. CNC milling shapes metal materials with accuracy as turning produces cylindrical parts. Precise drilling and threading avoidance guarantee attachments, and engraving includes the brand identification as well as cosmetic touches. In sum, CNC machining technologies allow manufacturing specialized racing components with high accuracy that improve track performance.

Types of Material You Can Use To Produce Racing Parts via CNC

CNC racing parts can be made from a wide range of materials, especially considering the fact that CNC machining is a versatile and fully adaptable type of manufacturing procedure.Commonly, the materials that are used for the production and manufacturing of CNC racing parts are:

CNC racing parts can be made from a wide range of materials, especially considering the fact that CNC machining is a versatile and fully adaptable type of manufacturing procedure.Commonly, the materials that are used for the production and manufacturing of CNC racing parts are:- Stainless Steel

- Aluminum

- Metal

- Brass

- Plastics

Common Finishes for CNC Racing Parts

Some standard processes that machine shops use for furnishing on CNC racing parts in order to create the finish include anodizing, powder coating and polishing. Anodizing offers a corrosion-resistant layer, as well as more colors. Powder coating facilitates longevity and is available in several colors, thus it becoming a favorite option of racing parts. Polishing leaves a shiny, smooth surface that has an appealing visual value. These finishes not only safeguard race components but also add aesthetics to the chassis making it aesthetic and protective on track.

Applications of CNC Racing Parts

CNC racing parts are used in different forms of motorsports which help to improve performance and increase their life. They are widely used in racing cars, motorbikes, and off-road vehicles. CNC racing parts strengthen engine systems, suspension system and aerodynamics to allow perfect speed in all race cars. In motorbikes, they improve engines and their exhausts as well as chassis components. CNC racing parts make off-road vehicles more tough and efficient in extreme conditions. Motorsport enthusiasts and professionals also need these components to gain an advantage on the track or off-road courses

CNC Racing Parts vs. Standard Manufactured Racing Parts

Racing parts, in simpler terms, are parts of any type of racing vehicle or equipment used by professionals for their racing events. Standard manufactured racing parts, on the contrary, are parts or components that are manufactured and produced using traditional ways and methods.Other than the process of how they’re made, there are also quite a few distinctive differences between racing seats that are manufactured via CNC and those that are manufactured using standard or manual methods, these include:

Racing parts, in simpler terms, are parts of any type of racing vehicle or equipment used by professionals for their racing events. Standard manufactured racing parts, on the contrary, are parts or components that are manufactured and produced using traditional ways and methods.Other than the process of how they’re made, there are also quite a few distinctive differences between racing seats that are manufactured via CNC and those that are manufactured using standard or manual methods, these include:- Material availability and selection

- Edge accuracy and precision

- Tighter tolerances

- Speediness and urgency of the production

Comparing CNC Racing Parts to Traditionally Manufactured Parts

- Premium accuracy, precision, and measurements on the final product

- Higher-quality of materials used

- Speed and urgency in delivery and time to market

- Versatility and flexibility in production

Disadvantages of CNC Racing Parts

- They’re not 100% excellent and high-quality, there’ll still be human intervention, but only minimal

- Typically, their costs are higher – products are more expensive than those that are produced regularly

- There are size limitations to CNC racing parts, too. You wouldn’t be able to manufacture big-sized parts

- The operator of the CNC machine requires skill and experience in order to pursue the product’s quality

Get the Best and Highest Quality of CNC Racing Parts

As we mentioned above, we here at HDC Manufacturing have been considered by businesses, companies, and organizations in and out of China as their one-stop-shop for CNC racing parts. CNC or not, we are known as the experts and virtuosos in the field of racing parts and components.

We have organized and streamlined our CNC racing parts manufacturing procedure, allowing us to produce simultaneous lines of components. Whether you need CNC racing car parts, motorcycle parts, bike parts, off-road parts, karts, or any other type of components, our team just got what you need!

Besides CNC racing parts, HDC Manufacturing is also the best when it comes to custom wheel lug nuts, CNC wheel spacers, CNC block guards, and many more!

What are you waiting for? Reach out to us! Shoot us a message and we will respond with a free quotation of whatever you need! Our team is always open to answering inquiries or concerns that you might have!

Guidance for Custom CNC Racing Parts From Manufacturers

To attain success when ordering custom CNC racing parts from manufacturers, apply a programmed approach. Start by defining what your parts call for: material, design specs, number of pieces and requirements on performance. Search and select qualified manufacturers with appropriate certifications and quality control measures. Ask for specific estimates and judge offers in terms of price, delivery time and ability to accommodate changes. Collaborate intensively with the chosen manufacturer to complete specifications, develop testable prototypes and meet regulatory standards.

State all terms, such as payment dates and delivery due date in a detailed contract. Keeping communication open throughout the project and attending to any concerns as soon they arise. After we receive the custom CNC racing parts, perform detailed quality checks and offer feedback for further improvements. This thorough approach guarantees a positive cooperation and the provision of superior custom-made racing parts based on your specifications as well as performance needs.

Conclusion

In the fast-paced environment of motorsports, CNC racing parts are a revolution; HDC Manufacturing is your go to. Having more than one decade of practice we are the best in manufacturing precision CNC racing car parts, motorcycle components and so on. From materials to the techniques, we have addressed everything. Though CNC parts give unparalleled quality, price and scale restrictions are important; skilled operators form an integral part. Contact us today for a free estimate and see the quality of personalized CNC racing parts made just to fit you.

Resources:

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!