Do you need clear anodized aluminum? Do you even know what it is? Have you ever had a chance to look at and see what they’re used for? In this blog, we’ll be discussing clear anodized aluminum at its peak.

You will know what clear anodized aluminum is, its purpose and applications, who use it, and many more!

What is Clear Anodized Aluminum?

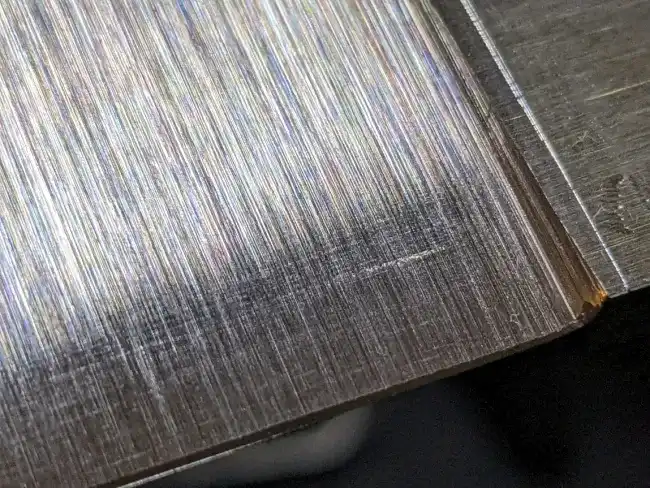

Don’t get too confused on what clear anodized aluminum is. In essence, it is just aluminum that went through electrochemical processes, enhancing its surface. It’s just anodized aluminum that remains uncolored, resulting in a silvery, grayish finish.

So, what this process does is create a durable oxide layer that protects the metal from corrosion, wear, and environmental damage while maintaining its natural metallic appearance.

This type of finish is widely used in architectural designs, automotive parts, and consumer products because it offers both durability and aesthetic appeal. Its sleek, metallic look fits modern design trends, while its resistance to scratching and fading ensures long-lasting performance.

NOTE: Unlike painted or coated finishes, clear anodizing integrates the protective layer into the metal, ensuring it won’t chip or peel.

Read More:

What is the Process of Creating Clear Anodized Aluminum

It’s not like you’ll create a new product out of thin air. What it is is actually transforming an untreated, unprocessed aluminum into something stronger, more durable, and more robust.

Therefore, without further ado, here’s the process of transforming aluminum into clear anodized aluminum.

Step 1: Preparation and Racking

To begin the process, aluminum sheets are clamped and tightly securely onto a conductive bar. This prepares the sheets for the start of the process.

What this does is ensure a tight hold and allow electricity to effectively pass through; this helps automate the entire anodizing process.

Step 2: Surface Cleaning

For the next step, the metal is prepared further by thoroughly cleaning the sheets in a specialized bath removing any surface impurities.

When it’s finally clean, the sheets are then transferred to a rinse bath using a crane to ensure no residue remains.

Step 3: Acid Bath Treatment

For this next step, the aluminum starts to get treated by being dipped into a fluoride-acid bath.

The fluoride reacts with the surface, creating a rough texture that eliminates imperfections. Afterward, the aluminum undergoes another rinse to prepare for the next stage.

Step 4: Fluoride Removal

Any remaining fluoride on the metal is removed through a thorough rinse, ensuring a clean and reactive surface for the subsequent process.

Step 5: Removing Silicon and Magnesium

For this step, the metal is placed in another bath to eliminate silicon and magnesium contaminants.

This purifies the surface further, making the aluminum more soluble and ideal for anodizing. The metal is again rinsed to complete this phase.

Step 6: Anodizing the Aluminum

Anodization is what’s considered to be the most critical part of the process. The aluminum is charged positively, and an electrical current is passed through an acid bath.

This creates a durable oxide layer on the surface, which takes approximately 30 minutes to form.

Step 7: Sealing the Coating

Finally, the anodized aluminum undergoes a sealing process to lock in the oxide coating. This step ensures the material becomes highly resistant to corrosion, extending its lifespan and durability.

There you have it! The clear and concise process of making clear anodized aluminum! Regardless of the application and use, the industry you are in, and the functionality you’re using them for, they’ll do what they’re supposed to do!

Anodized Aluminum vs. Non-Anodized Aluminum

Many people are convinced that aluminum itself is already a usage or application-ready, but is it true? Can they really suppress reactions and protect themselves from damage?

Check this video out as I Want to Cook compares an anodized aluminum from one that is non-anodized!

While both options have their merits, choosing between them depends on the application, environmental exposure, and desired properties. Let’s take a look at the difference between a non-anodized aluminum from one that is.

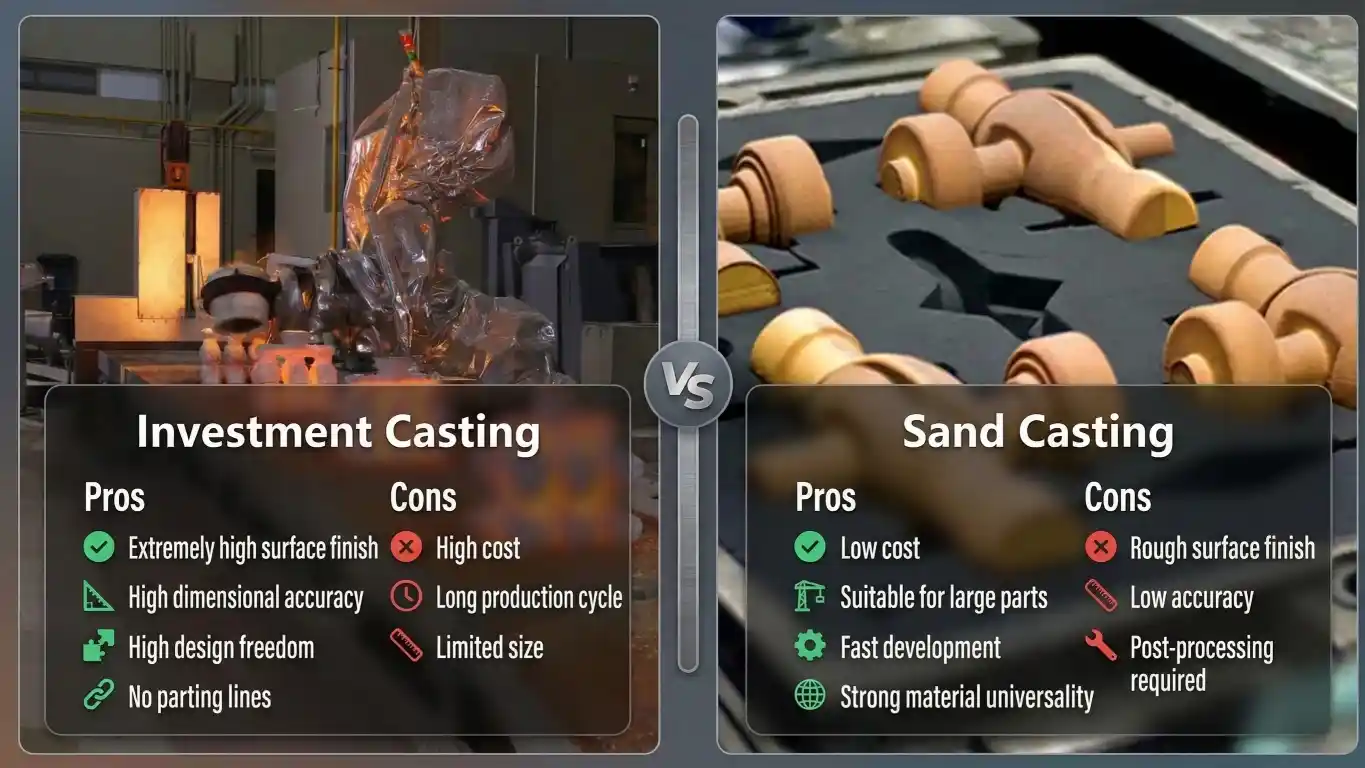

| Feature | Anodized Aluminum | Non-Anodized Aluminum |

| Process | Treated with an electrochemical anodizing process. | No additional surface treatment applied. |

| Durability | Highly resistant to corrosion, scratches, and wear. | Susceptible to corrosion and physical damage without a protective layer. |

| Appearance | Features a uniform, sleek, metallic finish with optional color options. | Retains a natural, raw metallic look with surface imperfections. |

| Maintenance | Easy to clean and requires minimal upkeep due to protective coating. | Requires regular maintenance to prevent tarnishing or oxidation. |

| Weight | Maintains aluminum’s lightweight nature while adding surface protection. | Lightweight and raw, with no additional layers or coatings. |

| Cost | Slightly higher due to the anodizing process. | More cost-effective without surface treatments. |

| Applications | Used in architecture, electronics, marine, and decorative projects. | Ideal for low-budget, indoor, or temporary applications. |

| Environmental Impact | Anodizing is eco-friendly and creates no hazardous waste. | No processing, but more prone to short lifespan and higher replacement needs. |

What do we learn from this? Both anodized and non-anodized aluminum have their strengths, but anodized aluminum is preferred for applications requiring durability, aesthetics, and low maintenance.

Non-anodized aluminum works best when cost is a major factor, or in situations with limited environmental exposure.

Do You Need Clear Anodized Aluminum?

Yes and no–let me explain why.

The purpose of using clear anodized aluminum is for projects and tasks that require low-maintenance, durable, and polished looks. You can think of it to be an advantage in the aesthetics side of things.

Anodization is a finish that further enhances the overall quality of aluminum. From the functionality standpoint to the visuals, it will appear better, higher caliber, and more effective.

Let’s take a look at the different avenues of applications of clear anodized aluminum.

Applications of Clear Anodized Aluminum

There are quite a few different applications of clear anodized aluminum, especially in specific sectors. But here are some of the business industries that heed its use:

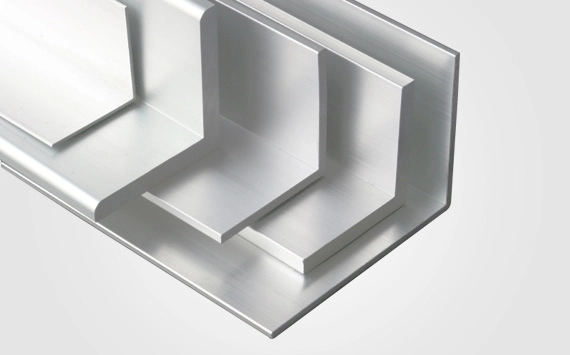

- Construction and Architecture: Doors, window frames, roofing systems, and building facades all frequently use clear anodized aluminum.

- Displays and Signage: Over time, clear anodized aluminum guarantees that signs and displays will continue to be aesthetically pleasing and resistant to weather.

- Automotive and Automobile Industry: Because it resists corrosion, clear anodized aluminum is frequently used for trim, emblems, and interior detailing

- Home Appliances: It gives appliances like ovens and refrigerators a sleek appearance and long-lasting durability.

- Aerospace and Defense: Aircraft components, such as panels and fittings, rely on anodized aluminum for its lightweight and protective qualities.

Consumer Electronics: This material’s smooth, long-lasting finish makes it perfect for devices like laptops, smartphones, and audio equipment.

Clear Anodized Aluminum Specifications

When it comes to the specifications of clear anodized aluminum, it doesn’t refer to specs of the aluminum itself, but rather the properties it has.

Exceptional Corrosion Resistance

Clear anodized aluminum is highly resistant to corrosion, making it ideal for both indoor and outdoor use. The anodized layer acts as a protective barrier, preventing moisture and environmental elements from damaging the surface.

Lightweight Yet Strong

Clear anodized aluminum retains aluminum’s lightweight nature while offering improved structural integrity. This makes it a popular choice for applications requiring strength without added weight.

Environmentally Friendly

Anodized aluminum is non-toxic and recyclable, contributing to eco-friendly manufacturing and sustainable design practices. It also avoids the need for harmful coatings or paints.

Enhanced Surface Hardness

This material boasts a significantly harder surface compared to non-anodized aluminum. The anodizing process creates a durable oxide layer, which protects against scratches, wear, and mechanical damage.

These are just some of the most common properties clear anodized aluminum has, overall. This isn’t everything, though, because there are a lot of things it’s good for. It will just depend on the industry you’re in and what you’ll be using it for.

Where Can You Order Clear Anodized Aluminum?

There will never be a shortage of clear anodized aluminum in the market. There are manufacturers and suppliers in every continent–even in most countries. The question is, which manufacturer should you trust your business with, and which of them can get you the best and highest quality of aluminum.

It’s no question that Chinese manufacturers are the best. Besides the fact that they have the most competition, they also get their products from a direct source!

And if you’re wondering which supplier to trust and go with, don’t think twice in approaching us here at HDC Manufacturing!

Why HDC Manufacturing is the Best Source of Clear Anodized Aluminum

HDC Manufacturing stands as the country’s best and most trusted manufacturer of aluminum. Whether you’re looking for raw aluminum or anodized ones, you can completely trust us.

Do you think you need to use clear anodized aluminum for your tasks and projects? Would you need the reliability and assurance they’re offering?

At HDC Manufacturing, you will never be left with questions. We’re known as the country’s best manufacturer of clear anodized aluminum, that are used in a vast plane of industries. Don’t hesitate to contact us if you have concerns, questions, or if you want clarification on the metals you’re buying.

Our team here at HDC Manufacturing will always be on the lookout to help you achieve your goals through the best and highest quality of components and materials we can get.

Contact us and get a free estimate! Besides aluminum, we’re also the best in manufacturing other products, too like stainless steel, titanium, and all other similar alloys. Reach out to us and get a free quote!