Stainless Steel Weld on Hinges

HDC is Your Premier Manufacturer Of Stainless Steel Weld on Hinges.

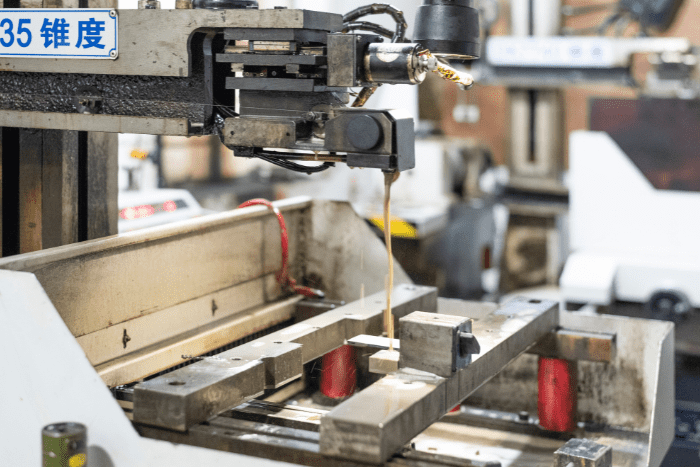

HDC has more than 13 years of weld-on hinges machining experience. We have a large stock of stainless steel weld-on hinges. With industrial leading machines and tools, you can get an excellent one-stop solution for your project.

- ISO9001 certificated supplier

- Excellent corrosion resistance

- Various sizes to choose from

- Superior strength and durability

- Keep the quality at a high level and consistent

Introduction Of Stainless Steel Weld-on Hinges

Stainless steel weld-on hinges consist of stainless steel body and bushing. To suit your different requirements, the length, material, and weight capacity can be adjusted. You can choose whether have grease fittings or not, and you can choose 304 or 316 stainless steel. With superior strength, durability, and resistance to corrosion, it is a good solution for environments outside. You can use stainless steel weld-on hinges in many areas, such as the military industry, medical industry, marine, and shipping industry.

All Different Stainless Steel Weld-on Hinges

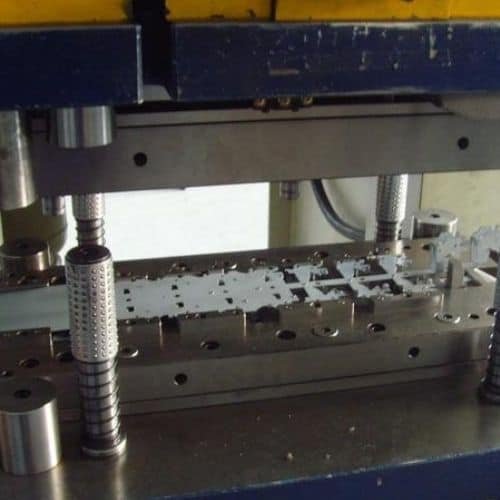

Our stainless steel weld-on hinges are made from 304 or 316L stainless steel, and the weight capacity is from 23kg to 642kg. To suit your different requirements, its length is optional from 40mm to 200mm, with all the hinges manufactured in CNC Machines.

Our stainless steel weld-on hinges are made from 304 or 316 stainless steel, with grease fittings as needed. The weight capacity is from 59kg to 600kg, and the length is from 60mm to 200mm for your requirements.

In addition to common sizes of stainless steel hinges, we can also customize hinges from your designs. After receiving your drawings, we can put them into production by your drawings.

Related Products You May Want

We also provide aluminum and steel weld-on hinges for your business.

1. Aluminum: consists of an aluminum body and 304 stainless steel bushings or pins. You can choose grease fittings as needed. They are light and durable. With excellent strength and corrosion resistance, it is a good solution for harsh elements outside. Aluminum weld-on hinges have a clean and smooth appearance and can be applied on safes, doors, gates, metal cabinets, and several other things.

2. Steel: consists of steel body, steel or brass pin, and washer. You can choose whether have grease fittings or not. Although it sounds ordinary, they have superior strength and durability. This type is an affordable option with excellent corrosion resistance. Steel weld-on hinges have a secure connection so that you can remove your door freely.

HDC Capabilities On Weld on Hinges

Stainless steel weld-on hinges| The Complete FAQ Guide

1. Why should you choose stainless steel weld-on hinges?

Stainless steel weld-on hinges provide reliable strength to your doors, gates, and other swing covers applications without increasing the weight of the product. Here are a few reasons you should choose stainless steel weld-on hinges:

- Corrosion-resistant

Stainless steel hinges are highly resistant to corrosion. This means that you can use stainless steel hinges in humid and damp areas. This makes the stainless steel hinges ideal for use in tropical forests, on ships, and in applications where humid weather is involved. Also, stainless steel is resistant to rust, therefore, the hinges remain intact despite exposure to a harsh and humid environment.

- Durable

The stainless steel hinges are very durable. It is mainly due to the structural strength of stainless steel that the hinges are durable. This is why stainless steel hinges have a high utility in heavy-duty industries and vehicles.

- Bear heavy loads

Stainless steel weld-on hinges are ideal for use in heavy-duty applications. These heavy-duty applications include vaults, trailers, fire escape doors, etc. Moreover, the stainless steel hinges are ideal for use in military applications where the equipment needs to be heavy-duty.

- Hinges are long-lasting

Due to the special corrosion-resistant nature of the stainless steel hinges, the hinges are good for long-term applications. This means that the hinges will not deteriorate any time soon and you can forget about them after installation.

2. What type of stainless steel is used by HDC for weld-on hinges?

HDC uses the 304-type and 316-type stainless steel for the manufacturing of SS weld-on hinges. We make different options available for our clients. You can choose from a stainless steel hinge with stainless steel pin configuration or any other configuration you require. Each of the configurations of pins and hinge body has a different application.

3. Where should I use the stainless steel hinges?

There are numerous applications of stainless steel weld-on hinges. Here are the most popular applications of weld-on hinges:

- Military Industry

Military vehicles and locomotives have a high demand for stainless steel weld-on hinges. This is primarily because stainless steel hinges are light in weight and provide great strength. Furthermore, the SS hinges are resistant to corrosion and therefore can survive for long in harsh and humid environments. The main applications in military vehicles involve submarine hatches, carriage doors, storage compartments, etc.

- Agricultural Industry

Another important area of application of stainless steel hinges is the agricultural industry. Mainly the barn doors, tractor doors, trailer doors, etc. have a high demand for SS weld-on hinges. These hinges are also suitable for the agricultural industry since there is a lot of humidity in agricultural areas and biological waste adds to the humid environment. Therefore, the SS hinges act as the perfect and long-lasting choice for agricultural applications.

- Medical Industry

Stainless steel weld-on hinges also have multiple medicine manufacturing and other related medical industry applications. In the medical industry, sterilization is of extreme importance. Stainless steel is ideal for resistance to bacteria and other pathogens. Also, it is very easy to sterilize stainless, therefore, stainless steel is an ideal choice for hinges in medical compartments, FEMA doors, panels, etc.

- Construction Industry

In the construction industry, the stainless steel weld-on hinges have a vital position. Lots of storage boxes and construction vehicles use stainless steel hinges. The construction industry requires materials that are light in weight, have high strength, and are not easy to corrode. As such, stainless steel hinges are the best choice for the construction industry.

- Marine and Shipping Industry

The shipping and marine industry also has a high application of stainless steel weld-on hinges. These hinges are usually installed in hatches, panels, compartments, and other areas around the ship. The weld-on hinges are ideal for ships and marine vehicles as they take very little space, are light in weight, and sustain the humid weather of the sea.