Maximizing Truck Performance with Wheel Spacers: A Comprehensive Guide

Explore the benefits of using wheel spacers for trucks, including improved stability, aesthetic enhancements, and increased clearance for larger tires. This guide covers types, materials, safety considerations, and detailed steps for choosing and installing the right wheel spacers to boost both performance and appearance.

Benefits of Using Wheel Spacers for Trucks

Improved Stability

One of the primary advantages of wheel spacers is the enhanced stability they provide. By widening the track of the vehicle, wheel spacers contribute to better handling, especially during turns and maneuvers.

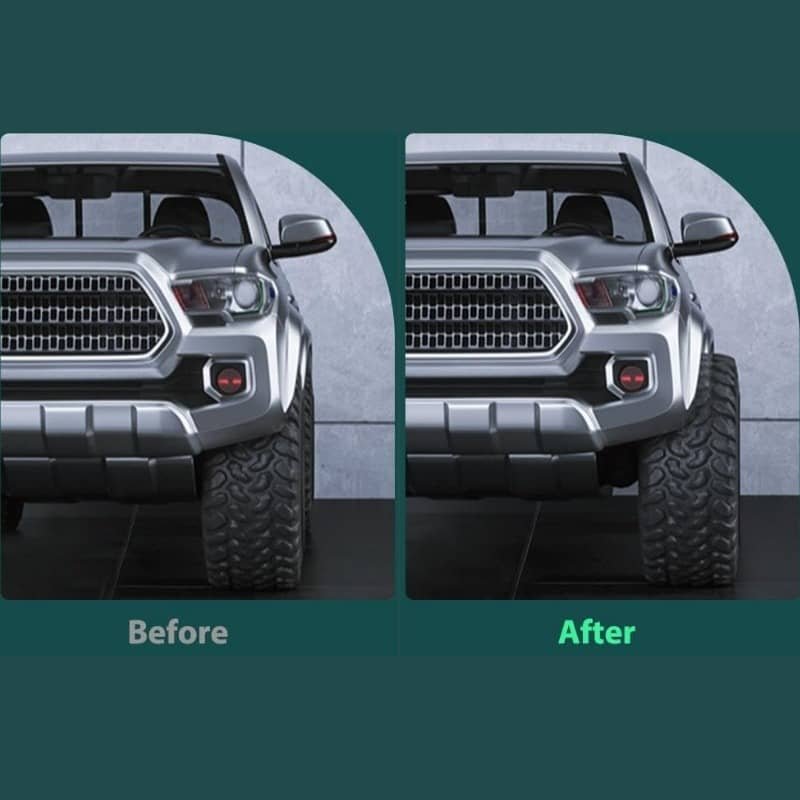

Enhanced Aesthetics

Beyond performance, wheel spacers offer a visual upgrade to your truck. The wider stance not only looks impressive but also gives your vehicle a more aggressive and commanding presence on the road.

Increased Clearance

Wheel spacers create additional space between the wheel and the vehicle’s body. This extra clearance is particularly beneficial when fitting larger tires or aftermarket brake kits.

Impact of Using Wheel Spacers on Off-Road Performance

Wheel spacers enhance off-road performance by providing a wider stance, improving stability on uneven terrain, enhancing cornering, and enabling the use of larger tires for better traction. However, wheel spacers may increase stress on components, alter steering dynamics, and pose risks of interference, requiring careful alignment adjustments and regular inspections to mitigate potential drawbacks.

Safety Considerations When Using Wheel Spacers

When using wheel spacers, prioritize safety by investing in high-quality, compatible spacers, ensuring professional installation, and adhering to torque specifications. Conduct regular inspections for wear and interference, maintain proper alignment, and monitor torque levels. Consider load capacity, adjust driving habits accordingly, and be prepared for emergencies with the necessary tools. If in doubt, consult automotive experts to enhance safety and enjoy a trouble-free off-road experience.

Types of Wheel Spacers for Truck

- Hub-Centric Wheel Spacers:

- Lug-Centric Wheel Spacers:

Materials and Finishes of Truck Wheel Spacers

- Aluminum:Lightweight, corrosion-resistant, suitable for most applications.

- Stainless Steel:Robust, handles heavy loads well.

- Composite Materials:Balanced strength and weight, various compositions available.

- Anodized Finish:Durable, corrosion-resistant, aesthetic options, but may wear over time.

- Powder Coating:Durable, chip-resistant, corrosion-resistant. Susceptible to damage.

- Zinc Plating:Corrosion resistance for steel spacers. Wear over time, especially in high-friction areas.

- Chrome Plating:Aesthetic appeal, and corrosion resistance. Prone to scratching, requires maintenance.

Manufacturing Process of Wheel Spacers

- CNC Machining:CNC machines are programmed to cut and shape the wheel spacer precisely according to design specifications. This method ensures high accuracy and consistency.

- Forging:his method can be used for certain metals, providing strength and durability to the wheel spacer. Forged spacers are often used in applications where high strength is critical.

- Casting:While not as common for wheel spacers, it is used for certain materials like aluminum. Cast spacers may be suitable for less demanding applications.

Choosing the Right Truck Wheel Spacers

- Wheel Size and Type:Ensure the spacer dimensions align with your truck’s wheel size and type for a balanced fit.

- Vehicle Model and Make:Identify your truck’s specific model and make sure to ensure compatibility with the selected wheel spacers.

- Bolt Pattern:Match the bolt pattern of your truck’s wheels with that of the wheel spacers to avoid fitting issues.

- Hub Centric vs. Lug Centric:Choose between hub-centric and lug-centric spacers based on your truck’s preferences and requirements.

- Suspension Components:Analyze suspension components to ensure the selected spacers accommodate your truck’s design.

- Tire Size and Clearance:Confirm that the spacers provide sufficient clearance for your truck’s tire size to avoid rubbing.

- Weight Bearing Capacity:Choose high-quality spacers with a weight-bearing capacity suitable for your truck’s load.

- Intended Use:Consider your truck’s primary use (off-road or daily commuting) to select spacers that match your driving conditions.

Installation and Maintenance of Truck Wheel Spacers

Installation:

- Lift the truck and remove the wheels.

- Clean the hub and mounting surfaces.

- Place the wheel spacer on the hub.

- Insert the wheel spacer bolts into the hub.

- Place the wheel on the spacer and secure it with lug nuts.

- Torque lug nuts to specifications.

- Lower the truck and inspect the condition of the wheels under full load.

Maintenance:

- Regularly check lug nut torque.

- Inspect wheel spacers for any signs of damage.

- Ensure proper wheel alignment.

- Clean and re-grease if applicable.

- Replace damaged or worn spacers promptly.

Custom Truck Wheel Spacers

When searching for custom truck wheel spacers, start by researching your truck’s specifications and spacing needs, considering factors like bolt pattern and hub size. Use search engines to find reputable manufacturers, checking reviews for reliability. Explore manufacturer websites for customization options, materials used, and certifications. Contact manufacturers directly to discuss your requirements and inquire about pricing, lead times, and additional services. Verify adherence to quality and safety standards, and read customer feedback for insights. Seek recommendations from truck communities, review customization options, and confirm shipping details and lead times. Take your time to ensure you choose high-quality wheel spacers that meet your needs and safety standards.

Conclusion

Truck wheel spacers offer a myriad of benefits, from improved stability to enhanced aesthetics. By understanding their functionality, choosing the right spacers, and following proper installation and maintenance procedures, truck enthusiasts can elevate their driving experience. As the automotive industry continues to evolve, keeping an eye on future trends ensures you stay at the forefront of truck customization possibilities.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!