Closed Die forging vs. Open Die forging are metal forging...

Precision Engineering Investment Casting Service

One-stop investment casting service from design, manufacturing, finishing, to shipping. Deliver precision castings for customers worldwide.

• ISO Certified

• One-Stop Solution

• Competitive Price

Investment Casting Services

Top investment casting foundry in China, delivering casting solutions for complex and precision components.

Vacuum Investment Casting

Casting in an oxygen-free environment brings castings with high precision and quality.

- Vacuum environment prevents defects

- Clean and smooth surface finish

- High dimensional accuracy

- Suitable for complex thin-wall structures

Learn More

Super Alloy Investment Casting

Cast with super alloys, built high-strength castings for demanding applications.

- Material range: Inconel, Hastelloy, etc.

- Suitable for high temperature and corrosive environments

- Perfect for turbine and engine components

Learn More

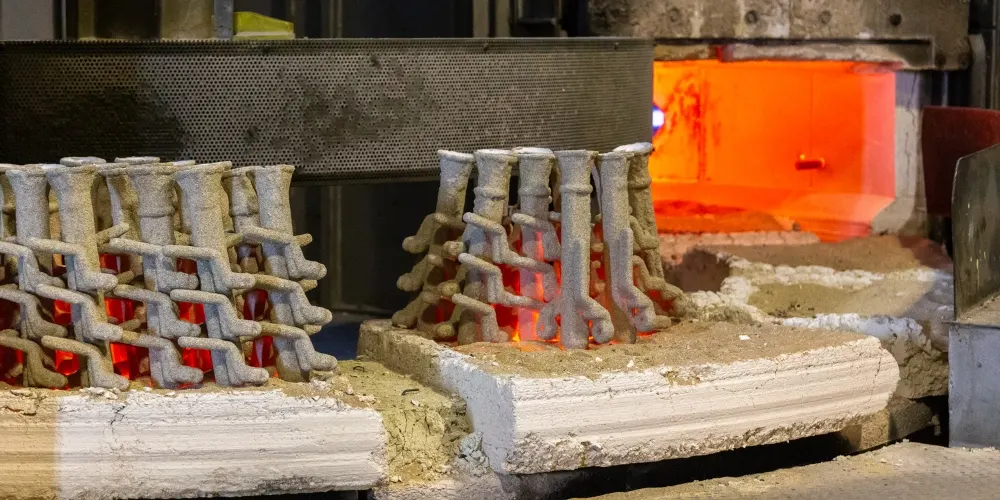

Heat Treatment

Precise control of temperature and cooling rate improves casting performance and eliminates defects

- Processes: Annealing, Normalizing, Quenching, and Tempering

- Eliminates casting stress, stabilizes dimensions & shape, and enhances mechanical properties

Learn More

Materials & Surface Finishes

Over 30+ metal materials are available in HDC to satisfy requirements in different applications

Investment Casting Materials

Superalloy

Inconel 718, Inconel 625, Incoloy, and Hastelloy

Surface Treatment

Sand/Bead Blasting

Cleans surface scale, rust, residue for a uniform matte or satin finish

Mechanical Polishing

Remove burrs and flashes for a uniform, smooth, high-gloss surface

Electroplating

Enhance wear and corrosion resistance by chromium or nickel coatings

Powder Coating

Balancing environmental friendliness with outstanding coating performance

Painting

Rich color options, enhanced corrosion resistance

Needs Different Material or Finish?

Don’t see your desired options in the list above? Don’t worry! HDC’s capabilities extend beyond standard options. Please consult with us for your special material and finish needs.

Industry We Serve

Diverse investment casting solutions for different industries with our over 15 years of expertise

Rigorous Quality Control

Our quality control goes through the whole casting process, from the material to the final product, ensuring every product meets your expectations.

Certifications:

✓ ISO 9001:2015

✓ ISO 14001:2015

✓ AS9100

Material Composion Anylize

Analyze the chemical composition with a spectrometer for the raw material

Mechanical Performance Testing

Hardness and tensile strength testing to ensure mechanical properties meet standards

Casting Process Control

Monitors key parameters throughout the investment casting process to ensure consistent quality

Fluorescent Penetrant Inspection

Detects defects in castings using a fluorescent dye and ultraviolet light for high-sensitivity flaw identification

Why Choose HDC

We deliver exceptional castings through custom solutions and precision manufacturing

One-Stop Solution

- End-to-end solutions from design to delivery

- Integrated in-house capabilities (tooling, casting, finishing, QA)

Rich Customization Options

- Over 30 materials and finishes available

- Custom alloy for specific applications

- Project-specific process optimization

Global Service

- Compile with international quality standards

- Multigualiul technical support

- Localized compliance expertise

Competitive Pricing

- Continuously optimizing the casting process to lower defect rates

- Leverage mature supply chains for cost-efficient sourcing

More About HDC

Go through our facility and equipment list, learn more about HDC's casting capabilities

| Equipment | Specifications | Quantity |

| Wax Injection Machines | – | 5 |

| Vacuum Melting Furnaces | 50kg, 100kg capacity | 2 |

| Medium Frequency Induction Furnaces | 250kg (2 units), 100kg (1 unit) | 3 |

| Shell Baking Furnaces | – | 2 |

| Heat Treatment Furnaces | – | 2 |

| Shot Blasting Machines | – | 5 |

| Sand Blasting Machines | – | 2 |

| Spectrometer | SPECTRO Germany, 5th Gen. Direct-Reading | 1 |

| Tensile Testing Machine | – | 1 |

| Power Supply System | 630kVA Box-type Transformers | 2 |

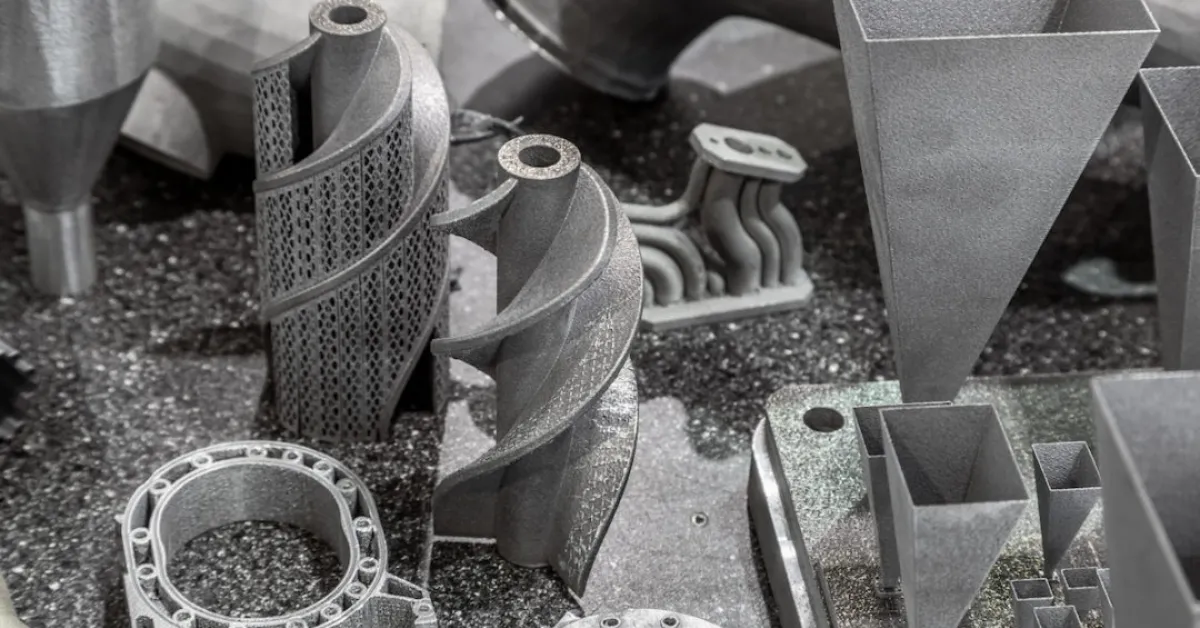

What is Investment Casting

Investment Casting is a precision casting process, also known as the “lost wax casting”. It is known for its ability to produce metal castings with extremely complex shapes, high dimensional accuracy, and good surface finish, especially for high melting point alloys or complex parts that are difficult to machine by other methods.

The Process of Investment Casting

The main process of investment casting can be divided into the following six steps:

- Wax Pattern Production: Create a metal mold based on the final part shape, then inject low-melting-point wax under pressure into the mold to obtain a precise wax pattern.

- Shell Building (Investment): The wax model is repeatedly immersed in the ceramic slurry, and after each dipping, a layer of fine sand made of refractory material is sprinkled, and this process is repeated several times until a ceramic shell with sufficient thickness (usually 5-15mm) and sufficient strength is formed on the surface of the wax mold

- Dewaxing (Wax Removal / Lost-Wax Process): After the ceramic shell is dried and hardened, it is placed in a high-temperature steam oven to allow the wax mold inside to melt and flow out, which is also the origin of the name “lost wax casting”.

- Shell Sintering: Place the dewaxed ceramic shell into a high-temperature furnace for firing to enhance its strength.

- Casting: Pour the molten metal into the cavity of the shell mold.

- Shell Removal & Post-Processing: After the metal is completely solidified, the outer layer of ceramic shell is removed by mechanical vibration, sandblasting, etc. The gating hole is then cut off, and subsequent processes such as heat treatment, sandblasting, polishing, machining, and surface treatment are carried out as required.

Investment Casting Flow

Below is our comprehensive investment casting process flow

FAQ

Answers for commonly asked questions about our investment casting service

Yes, with our experienced engineers and in-house CNC machining capability, we can design and manufacture molds, providing rapid support for design changes.

Yes, we provide scalable production services, from prototypes to mass production runs of over 2,000 units per month. HDC can meet all your needs

Yes, we provide prototypes for quality verification and function adaptation tests before mass production.

We can cast parts with a weight from 0.1kg to 100kg and size within 500mm x 500mm x 500mm.

Yes, we offer after-sales service and are responsible for quality issues caused by the manufacturing process and material.

We offer air, sea and rail transportation, as well as express delivery services. If you have different requirements, please contact us for details.

Get a Free Quote

Ready to discuss your requirements? Our engineering team is standing by to provide expert consultation and competitive pricing.

Request Free Quote

Related Resources

Top 20 Aluminum Forging Manufacturers in China 2024

The following lists the top ten aluminum alloy forging enterprises...

Comparison of Metal 3D Printing, Forging, and Investment Casting

Discover the differences between metal 3D printing, forging, and investment...

Metal Investment Casting vs. Metal Forging: 8 Things to Consider

Choosing between investment casting and forging depends on your specific...

Aluminum Forging: Crafting Durability and Efficiency Across Industries

Forging aluminum is a major component of modern manufacturing industry...