Superalloy Casting Parts Global Supplier

HDC is a global foundry specializing in precision casting. We offer a wide range of materials, including nickel-based, cobalt-based, and iron-based superalloys.

With our investment casting and sand casting capabilities, we can cast parts ranging from 0.1 kg to tons with intricate designs and high-quality surfaces.

Click the button below and fill out the form with your specifications, get a quick quote within 24 hours.

Industries We Serve

Aerospace

The high-temperature performance of the superalloy ensures the reliability of engine components such as turbine blades under extreme operating conditions

Energy

Super alloy castings have excellent corrosion resistance and fatigue resistance, which can significantly improve the life and stability of power generation equipment

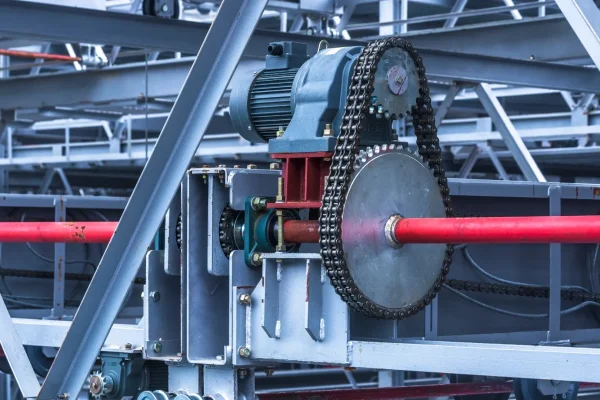

Industrial Machinery

Components used in heavy industrial machinery require excellent heat resistance and wear resistance to ensure long-term stable operation.

Superalloys We Cast

At HDC, we cast a wide range of superalloys, including nickel-based, cobalt-based, and iron-based. All your material requirements can be satisfied here.

IN718 is one of the most widely used forging and casting superalloys in the aerospace field. It has good comprehensive properties, including high-temperature strength, fatigue resistance, oxidation resistance and corrosion resistance.

IN713 is a super alloy specially developed for casting. It has good fluidity, easy casting, and can maintain good performance at a high temperature of 900°C.

The Rene@ series is a renowned family of high-performance nickel-based superalloys developed by General Electric. It exhibits exceptional high-temperature strength and thermal stability, but the casting process for Rene alloys is complex, typically requiring vacuum melting and precision casting.

Haynes 25 (CoCr21Ni27Mo5.5) is a cobalt-based cast superalloy. Its high Cr content(~28-30%) gives it excellent resistance to sulfuration, oxidation and hot corrosion.

Incoloy 901 is a cost-effective iron-nickel (Fe-Ni) based superalloy known for its excellent high-temperature mechanical properties. It has high strength and outstanding fatigue resistance at temperatures up to approximately 650°C (1200°F), combined with good oxidation resistance. While it operates at lower temperatures than nickel-based alloys, it offers significantly lower material and processing costs.

Post Treatments We Offer

We offer comprehensive post-treatments to enhance quality, performance, and reliability.

Heat Treatment

Pickling

CNC Machining

Sand Blasting

Bead Blasting

Polishing

Superalloy Casting Parts

We offer precision-cast superalloy components for demanding high-performance applications with over 10 years expertise.

Why Choose HDC Superalloy Casting

One-Stop Solution: HDC offers a tailored one-stop solution from design, casting, post-processing, to shipping, ensuring quick development and delivery.

Material Expertise: We are experts in the area of superalloy casting process, material configuration, composite analysis, and heat treatment technology, and can provide the best solution for your material requirements.

Comprehensive Custom Options: HDC provides custom options,

including material, post-treatment, finishes, packing, and shipping methods.

Competitive Price: As an experienced superalloy foundry, we handle almost all processes in-house, including post-process and precision machining, which enables us to offer a competitive price on the market.

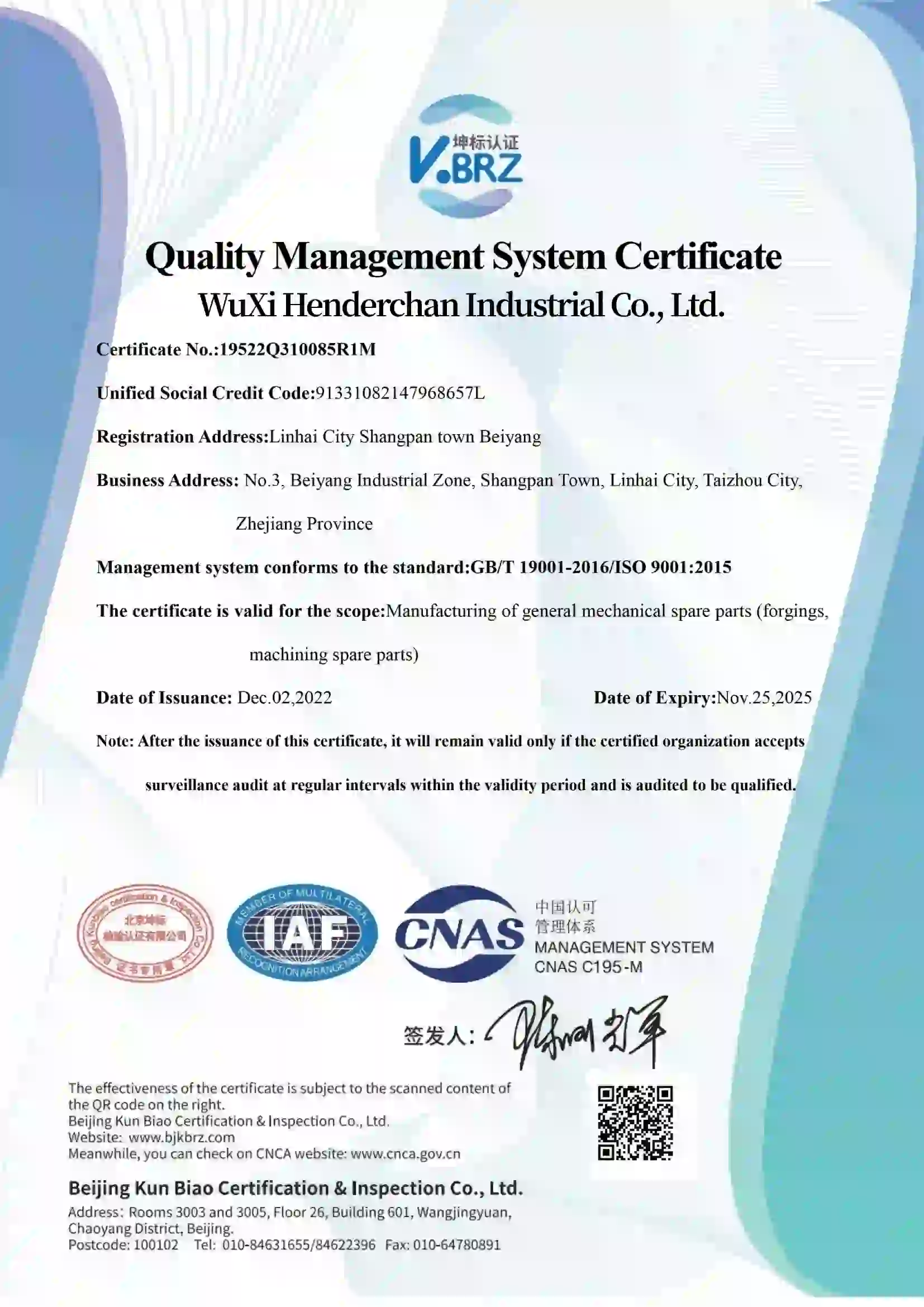

ISO Certified Quality: HDC is an ISO- certified foundry, we follow strict quality control protocol from raw material inspection, in-process monitoring, defect detection, to final finishing. We aim to deliver superalloy castings with unmatched quality to boost your business.

Customization Products With a Simple Quote!

We mainly provide investment casting and sand casting for superalloy castings. With sand casting, we can cast large parts that weigh tons. For small and medium-sized precision parts that require less post-processing, we use the investment casting process for production.

Yes, typically, we need an MOQ, it is because the casting process requires a pattern or mold, which can significantly increase the unit price with a small volume. We can discuss the specific MOQ based on the project, don't hesitate to contact us via email, WhatsApp, or phone.

Yes, we can provide all documents that you need, including material certification, ISO certification, and quality inspection report.

We primarily offer two shipping terms: DDP (Delivered Duty Paid) and FOB (Free On Board). We are open to discussing different terms you need.

Absolutely, the specific discount is determined according to the quantity.

Yes, all customers are welcome to see our factory, please contact us in advance to get an appointment.