Overview

HDC has over a decade of experience in the custom metal components field. We possess precision 4-axis and 5-axis machine tools, automated CNC machining centers, and a professional design and production team. We can provide you with various machining processes, including CNC milling, CNC turning, laser cutting, metal casting, and more, to craft your Titanium Grade 5 components to perfection, tailored to your specific requirements.

[toc]

What Is Titanium Grade 5?

Titanium Grade 5, also known as Titanium 6Al-4V.It has high corrosion performance, and strength close to 6061-T6 aluminum. Therefore, grade 5 alloy is the most extensively used titanium grade. It is commonly suitable for many applications. Including fuselage parts, condenser tubes, scouring baskets, and biomedical implantations, and more.

Other Names for Titanium Grade 5

Ti-6Al-4V, commonly referred to as “Titanium grade 5”, and also known as Ti-6Al-4V, is a titanium alloy which is the most common consists of 6% aluminum and 4% vanadium. It is given code name UNS R56400 and is formed according to ASTM/ASME standards like ASTM B348, B381, and B367. It follows AMS standards such as AMS 4928 and AMS 4907 while in military and aerospace areas. While there might be differences in the brand names, the formula’s composition and properties will still be identical among the applications it is used in.

Advantages and Disadvantages of Titanium Grade 5

Ti-6Al-4V, considered to be Titanium Grade 5, has a very unique characteristics of sheer strength to weight ratio, corrosion resistance, biocompatibility, high temperature tolerance and weld ability, which makes it a total right choice for aerospace, medical and industrial scenarios. Nevertheless, it is expensive, non-machinable, contaminated easily, not in sufficient sizes and/or forms, and has thermal expansion that is different to that of other materials which makes its employment a challenge. In spite of the fact that this has disadvantages, its property mix is usually an important all-rounder that overtakes the restrictions, especially in the role where its exceptional performance features are very important.

The Differences Between Titanium Grade 5 and Grade 1~4

The Grade 5 Titanium, or Ti-6Al-4V, stands out from Grades 1 to 4 providing its alloy composition, containing 6% of aluminum and 4% of vanadium, that gives higher strength and hardness composites, which are in demand in some industries like aerospace. That has made all titanium grades as perfect corrosion resistant and biocompatible ones; however, the alloying elements of Grade 5 can enhance their mechanical properties, although they also cost more. Further, Grade 5 titanium has relatively more weldability and machinability relative to other grades, making it the go-to material in the applications where extremely high mechanical performance is needed, even though it may slightly compromise corrosion resistance.

Chemical Composition of Titanium Grade 5

| Element | Content (%) |

| Titanium, Ti | 87.6 – 91 |

| Aluminum, Al | 5.5 – 6.75 |

| Vanadium, V | 3.5 – 4.5 |

| Iron, Fe | 0- 0.40 |

| Oxygen, O | 0-0.20 |

| Carbon, C | 0-0.08 |

| Nitrogen, N | 0-0.05 |

| Hydrogen, H | 0- 0.015 |

How Does Chemical Composition Affect Titanium Grade 5?

Many properties of Titanium Grade 5, including its high tensile strength and corrosion resistance, come from the chemical composition of the alloy that consists of more than 90% titanium, 6% aluminum, and 4% vanadium. Addition of aluminum and vanadium imparts strength, hardness and toughening to the alloy than that of pure titanium. On the other hand, the formation of an oxide layer that is stable and adherent is also facilitated by aluminum and this gives good corrosion resistance. Vanadium dominates the alloys in its strength, especially at a high temperate, and also improves the microstructure, which enhances the mechanical properties of the alloys. These same alloying elements also affect other features such as weldability, machinability, and biocompatibility, thus TG-5 Ti is a versatile material that is applicable in aerospace, medical, and industrial scenarios.

Thermal Properties of Titanium Grade 5

| Thermal Properties | Metric | English |

| CTE, linear 20°C | 8.6 µm/m-°C | 4.78 µin/in-°F |

| CTE, linear 250°C | 9.2 µm/m-°C | 5.11 µin/in-°F |

| CTE, linear 500°C | 9.7 µm/m-°C | 5.39 µin/in-°F |

| Specific Heat Capacity | 0.5263 J/g-°C | 0.126 BTU/lb-°F |

| Thermal Conductivity | 6.7 W/m-K | 46.5 BTU-in/hr-ft²-°F |

| Melting Point | 1604 – 1660 °C | 2920 – 3020 °F |

| Solidus | 1604 °C | 2920 °F |

| Liquidus | 1660 °C | 3020 °F |

| Beta Transus | 980 °C | 1800 °F |

Mechanical Properties of Titanium Grade 5

| Properties | Metric | Imperial |

| Tensile strength | 895 MPa | 130000 psi |

| Yield strength | 828 MPa | 120000 psi |

| Poisson’s ratio | 0.31 | 0.31 |

| Elastic modulus | 105-120 GPa | 15200-17400 ksi |

| Shear modulus | 41-45 GPa | 5950-6530 ksi |

| Elongation at break | 10 % | 10 % |

Physical Properties of Titanium Grade 5

| Density | Beta Transus | Melting Point | Thermal conductivity | Modulus of elasticity | Shear Modulus |

| 4.43g / cm³ | 980 °C | 1604-1660 °C | 6.7W / (m-K) | 1,6500 Ksi | 6380 Ksi |

Challenges in Processing Titanium Grade 5

Processing of Titanium Grade 5 also is accompanied by certain problems that are mostly derived from its specific structure and features. One of the major challenges is the poor machinability as compared to conventional metallic materials such as steel and this may lead to increased wearing of tools, lower processing speeds and higher production costs. Although Titanium Grade 5 may also become hardened by work, the tool changing frequency must be increased and the machining techniques must be carried out carefully to obtain exact dimensions and surface finish. On the other hand, it reacts strongly with oxygen, nitrogen, or hydrogen at high temperature which might be a limitation during processing, especially when the processing conditions are not controlled, which may result in contamination and hence mechanical properties being affected. Furthermore the high melting point and low thermal conductivity make gas welding, casting and other fabrication processes more difficult necessitating specialized equipment and skills. Notwithstanding these challenges, developments in processing technologies, tooling materials, and process control techniques, keep on enhancing the level of efficiency and feasibility when working with Titanium Grade 5 thereby promoting its adaptability in the many sensitive applications.

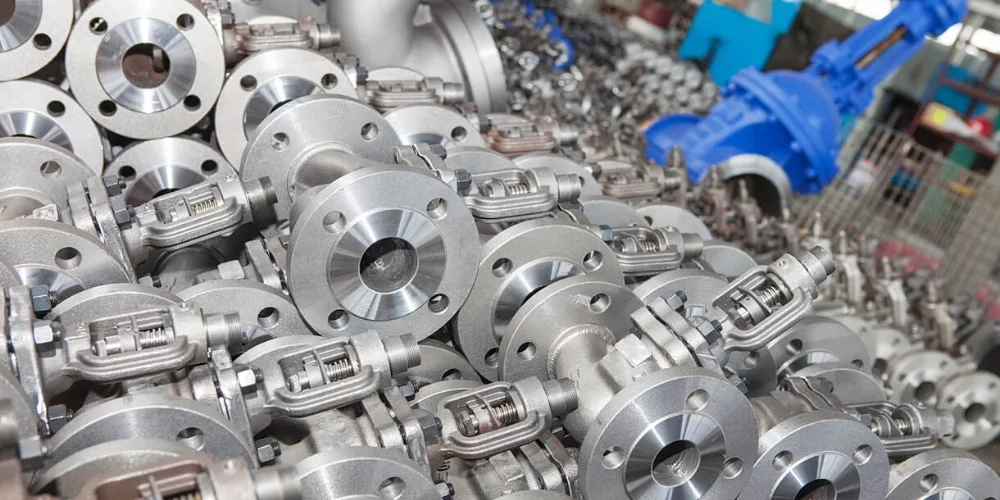

Applications of Titanium Grade 5

Titanium Alloy Grade 5 or Ti–6Al–4V is widely used in many different sectors owing to its unique blend of properties. In aerospace, it is utilized for both aircraft structural parts such as airframes, engine parts, landing gear and fasteners because of its good strength-to-weight ratio, corrosion resistance and temperature resistance. The Titanium Grade 5, in the medical field, is used for medical implant, orthopedic devices, and dental implants stemming from its biocompatibility, the resistance to body fluids and the ability to promote osseointegration. The alloy is also widely applied in marine applications for the constituent parts that are exposed to sea water because of its marvelous anti-corrosion characteristics. As well it is used for pipelines, pumps, valves, or compression fittings in chemical processing equipment, sports equipment, automotive components, and industrial machinery that require strength, corrosion resistance, and lightweight properties. Thanks to its versatility and performance, Titanium Grade 5 becomes non-replaceable in applications where devices’ reliability, durability, and performance under extreme conditions are inevitable.