Precision Steel Casting Parts Supplier Casting is an essential manufacturing...

Custom Metal Casting Solutions for Global Industries

HDC is an ISO-Certified Foundry Serving 50+ Countries Since 2009 - Get Your Free Quote in 24h

• ISO 9001 Certified Quality

• Fast Global Delivery

• One-Stop Solutions

Our Casting Services

We offer a wide range of casting options to meet your various metal casting needs

Investment Casting

Precision casting process that is perfect for medium to small parts with a weight range from 10g to 50kg.

- Ultra-thin wall castings starting from 0.5mm

- High surface accuracy

- Capable of casting over 300 types of alloys

Learn More

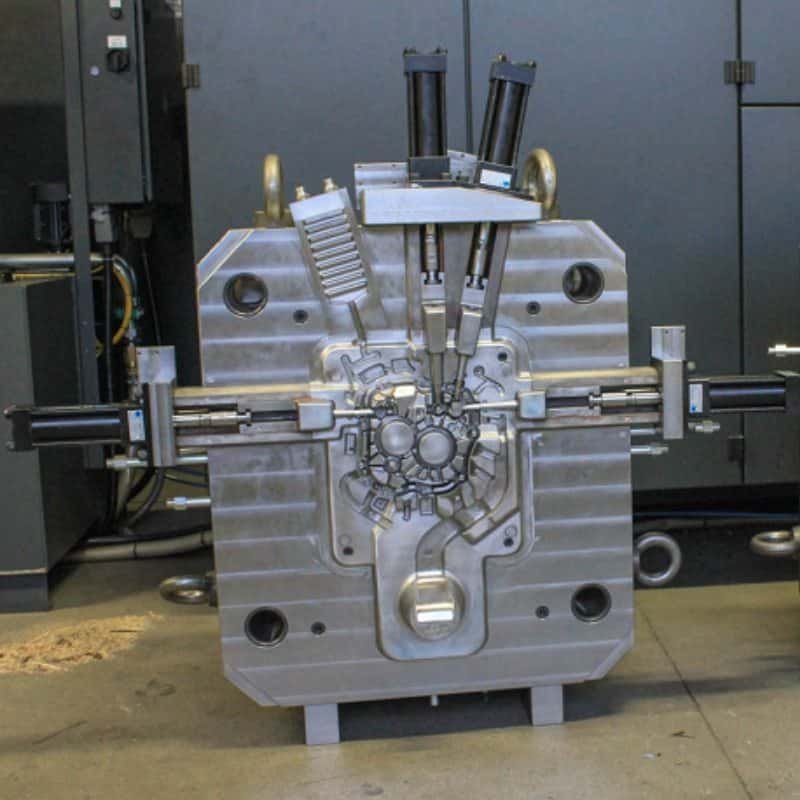

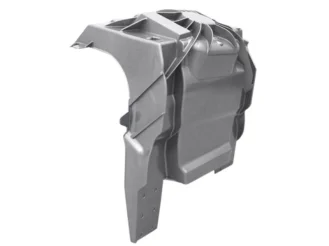

Die Casting

The most precise and highly efficient casting methods, widely used in the electronics and automotive industries.

- Zinc/magnesium/aluminum alloy high-speed casting

- Complex structure available

- Cost-effective for mass production

Learn More

Sand Casting

A flexible casting method for prototypes and low-volume production, ideal for casting large parts

- Low mold cost

- 1600°C+ heat resistant superalloy casting

- Capable of casting metal parts from 0.5kg to 20 tons.

Learn More

Materials & Surface Treatment

Comprehensive materials and finishing options for our custom metal casting service

Casting Materials

Carbon Steel

1010, 1020, 1045, 1060, 1080

Super Alloy

Inconel 625, 718, Hastelloy X

Aluminum Alloy

A357, A380, A443, A514

Magnesium Alloy

AZ91D, AM50A, AM60B

Surface Treatment

Machined

CNC machined for tight tolerance

Sand/Bead Blasted

Remove burrs and surface defects

Heat Treated

Plated

Powder Coated

Superior durability, environmental friendliness

One-Stop Casting Solutions

First time to purchase casting service online? Don’t worry! HDC offers you a one-stop metal casting service from design, manufacturing, to shipping.

Industries We Serve

Delivering cast components across diverse sectors with specialized industry expertise

Automotive

Engine blocks, transmission housings, brake components, suspension parts

Machinery

Pump housings, valve bodies, gear cases, industrial equipment

Construction

Heavy equipment parts, structural components, excavator parts

Marine

Propellers, hull fittings, engine components, offshore equipment

Energy

Turbine components, pipeline fittings, renewable energy parts

Electrical

Motor housings, transformer components, electrical enclosures

Precision Quality Assurance

Our commitment to excellence drives every aspect of our foundry operations, supported by international certifications and advanced quality systems.

International Certifications:

✓ ISO 9001:2015 Quality Management System

✓ ISO 14001:2015 Environmental Management

✓ IATF 16949 Automotive Quality Standard

Quality Control

3D Scanning (≤±0.05mm), X-Ray Defect Detection, CMM measurement

100% Inspection

Every casting undergoes comprehensive quality verification

Supplier Qualification

Rigorous raw material supplier auditing ensure high quality materials

Global Standards

Compliance with ASTM, DIN, JIS, and other international standards

Why Choose Our Foundry

Over 10 years of casting excellence delivering superior components worldwide

Technical Expertise

- Advanced metallurgical engineering team

- State-of-the-art foundry equipment

- Continuous process optimization

- Capable of developing new alloys

Production Capacity

- 5000+ tons annual casting capacity

- Flexible batch sizes from prototype to mass production

- Multiple casting processes available

Global Reach

- Worldwide shipping and logistics

- Multi-language technical support

- International quality standards

Custom Solutions

- Application-specific alloy development

- Prototype and tooling services

- Design optimization consultation

- Complete supply chain management

Custom Casting Service Process

Follow the straightforward metal casting service process, ensuring smooth project progress

1. Quotation

Upload your drawings or specifications. We offer detailed quote within 24 hours.

2. Design Review

Technical analysis of your requirements and design optimization recommendations

3. Prototyping

Sample production for approval before full-scale manufacturing begins

4. Production

Mass production with continuous quality monitoring and progress updates

5. Delivery

Final inspection, packaging and worldwide traceable distribution

More About HDC

Learn more about HDC, including our equipment and certifications, and gain more confidence to cooperate with us

| Equipment | Specifications | Quantity |

| Wax Injection Machines | – | 5 |

| Vacuum Melting Furnaces | 50kg, 100kg capacity | 2 |

| Medium Frequency Induction Furnaces | 250kg (2 units), 100kg (1 unit) | 3 |

| Shell Baking Furnaces | – | 2 |

| Heat Treatment Furnaces | – | 2 |

| Shot Blasting Machines | – | 5 |

| Sand Blasting Machines | – | 2 |

| Spectrometer | SPECTRO Germany, 5th Gen. Direct-Reading | 1 |

| Tensile Testing Machine | – | 1 |

| Power Supply System | 630kVA Box-type Transformers | 2 |

What is Casting

Casting is a process in which molten metal is poured into a mold containing a cavity (the shape of the cavity is the shape of the desired product), relying on gravity or pressure to fill the cavity with molten metal, and the molten metal is cooled and solidified into a part.

Advantages of Casting

- Diverse Casting Process: Over 10 types of casting processes, such as sand casting, lost wax casting, die casting, etc., are designed to satisfy different processing needs.

- Material Adaptability: From iron, steel, aluminum to superalloy, you can cast with any common metal material.

- Complex Geometry Achievable: Hollow structures, thin wall structures, and internal channels. Complex geometry that is impossible with machining can be easily cast.

- Low Cost of Mass Production: The mold is reusable, offering significant cost advantages for large-scale manufacturing.

Disadvantages of Casting

- Lower Mechanical Properties: Castings have coarser grains, and the strength of the casting is less than that of the forging under the same material.

- High Initial Cost: Die casting and investment casting require the production of precise molds, which may involve significant upfront investment

- Internal Defects: Although internal defects such as porosity, shrinkage porosity, and sand inclusion can be reduced by controlling the casting rate, cooling rate, and using vacuum casting, it is still impossible to completely avoid them

- Limited Dimensional Accuracy and Surface Quality

Types of Casting

Comparison of characteristics, applicable metals, and tolerance levels for common casting methods.

| Casting Process | Mold/Pattern Type | Suitable Metals | Accuracy/Surface Finish | Production Rate |

|---|---|---|---|---|

| Sand Casting | Sand Mold (Disposable) | Almost all metals (Fe, Steel, Al, etc.) | Low (CT11-14), Rough | Low-Medium |

| Permanent Mold Casting | Metal Mold (Reusable) | Low-melting alloys (Al, Mg, Cu) | Medium-High (CT8-10), Smooth | High |

| Die Casting | Metal Mold + High Pressure | Al, Mg, Zn alloys | Very High (CT6-8), Excellent | Very High |

| Investment Casting | Ceramic Shell (Disposable) | All metals (esp. superalloys) | Highest (CT4-7), Smooth | Low |

| Lost Foam Casting | Dry Sand + Foam Pattern | Cast iron, Steel, Al | Medium-High (CT6-9), Smooth | Medium-High |

| Low Pressure Casting | Metal Mold + Low Pressure | Mainly Al, Mg alloys | High (CT7-9), Smooth | Medium-High |

| Centrifugal Casting | Rotating Metal/Sand Mold | Fe, Steel, Cu, Al | Good OD surface, ID machined | High |

FAQ

Get answers to common questions about our casting service.

Simply send us your drawings or specifications through our website contact form, email, or WhatsApp. We typically provide detailed quotations within 24 hours.

We accept all major CAD formats including STEP, IGES, STL, SolidWorks, AutoCAD, and PDF technical drawings. Our engineering team can also work from samples or sketches to develop your casting solution.

Yes, we can design and manufacture the casting molds, dies, and patterns in-house. Our in-house tooling capability ensures better quality control and faster turnaround times.

Yes, the mold fee needs to be paid in advance. But for large quantity orders, we will refund the mold cost in the subsequent pickup.

There's no strict minimum order quantity - we can discuss it on the specific project.

Lead times vary based on complexity and quantity:

- Prototypes: 3-6 weeks

- Small batches (1-100 pieces): 4-8 weeks

- Large production runs: 6-12 weeks

Rush orders can be accommodated with expedited timelines.

Our facility is ISO 9001:2015 certified, and we maintain strict quality control throughout the casting process. We provide material certificates, dimensional inspection reports, and can accommodate additional certifications as required by your industry.

Yes, we will be responsible for all quality problems caused by materials or manufacturing processes, and provide free rework service.

Get Your Custom Quote Today

Ready to discuss your forging requirements? Our engineering team is standing by to provide expert consultation and competitive pricing.

Request Free Quote

Related Resources

Inconel 718: Composition, Characteristics, and Applications in Casting

Inconel 718 is a robust nickel-based superalloy recognized for its...

Custom Investment Casting Parts

Investment Casting Metal Parts Manufacturer Casting is a versatile metal...

Exploring the World of Stainless Steel Investment Casting

Stainless steel investment casting, which is also known as stainless...