Premium Custom Metal Forging Solutions

Leading Chinese manufacturer delivering precision-forged metal components to global markets with unmatched quality and reliability

- ISO 9001 Certified

- Global Shipping

- Custom Design

Our Forging Services

Comprehensive metal forging solutions tailored to your specific requirements with precision engineering and quality assurance

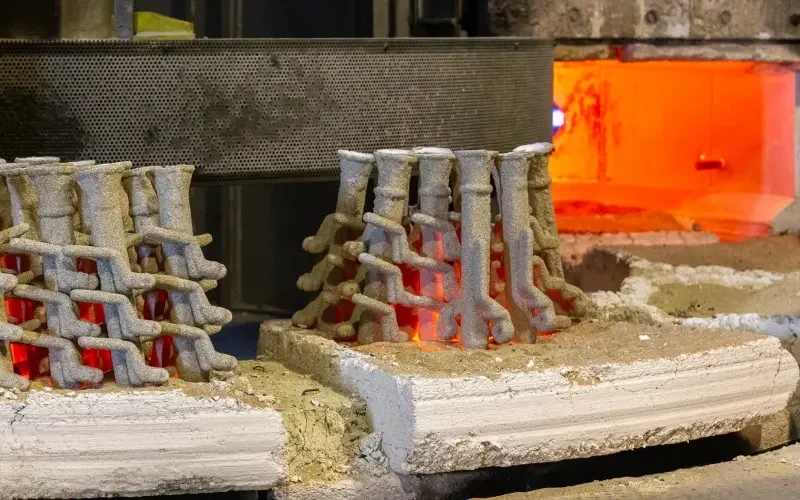

Hot Forging

High-temperature forging for complex shapes and superior material properties

- Temperature range: 950°C – 1250°C

- Complex geometries achievable

- Excellent material flow

- Superior mechanical properties

Close Die Forging

Precision close die forging for consistent, high-quality components, near-net shape forging with 0.01mm tolerance.

- Tight dimensional tolerances

- Consistent part-to-part quality

- Complex internal features

- High production efficiency

Roll Forging

Advanced roll forging technology for efficient production of stepped shafts, axles, and cylindrical parts.

- Continuous production process

- Excellent material utilization

- Precise diameter transitions

- Cost-effective for high volumes

Materials & Surface Finishes

Wide range of materials and finishing options to meet your exact specifications and performance requirements

Materials We Forge

Carbon Steel

1010, 1020, 1045, 1060, 1080

Copper Alloys

Brass, Bronze, Phosphor Bronze

Surface Finishes

As-Forged

Natural forge finish with scale

Machined

Precision machined to specified tolerances

Shot Blasted

Clean, uniform surface texture

Heat Treated

Plated/Coated

Custom Material Solutions

Don’t see your required material or finish? Our metallurgical experts can work with exotic alloys and specialized treatments to meet your unique requirements.

Industries We Serve

Delivering forged components across diverse industries with specialized expertise

Aerospace

Aircraft components, turbine parts, landing gear

Construction

Heavy machinery parts, structural components

Energy

Oil & gas equipment, renewable energy components

Marine

Ship components, offshore equipment

Industrial

Machinery parts, industrial equipment

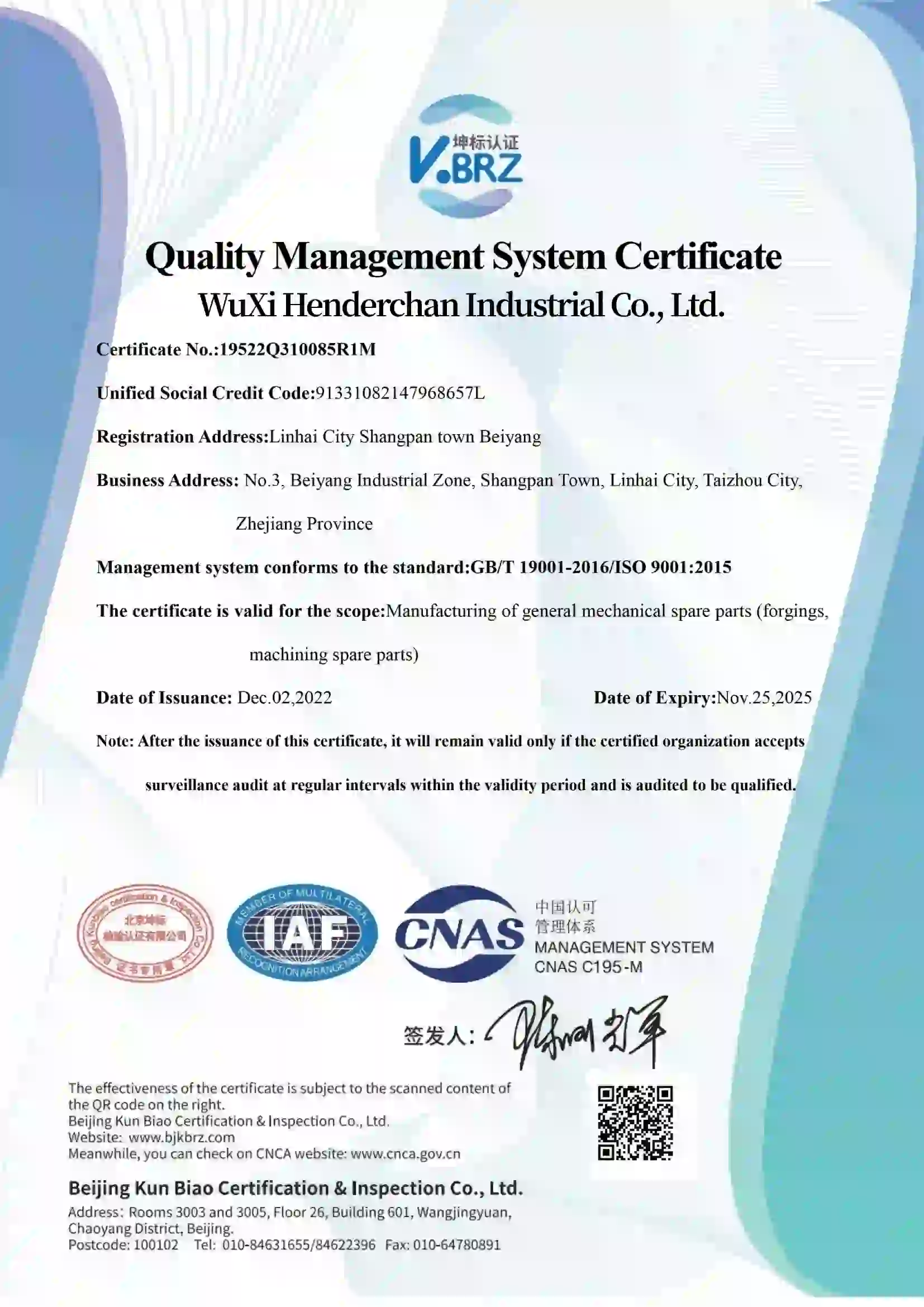

Uncompromising Quality Standards

Our commitment to excellence is reflected in every component we forge, backed by international certifications and rigorous quality control processes.

International Certifications:

✓ ISO 9001:2015 Quality Management

✓ ISO 14001:2015 Environmental Management

✓ AS9100 Aerospace Quality

Advanced Testing

Comprehensive material testing including tensile, impact, and hardness testing

100% Inspection

Every component undergoes rigorous quality inspection before shipment

Traceability

Complete material and process traceability for full accountability

Global Standards

Compliance with ASTM, DIN, JIS, and other international standards

More About HDC

Learn more about our factory, equipment, manufacturing process, and post finishes.

| Equipment | Quantity | |

|---|---|---|

| Forging | Electric screw press (160T-4000T) | 22 |

| Forging Press (160T-1000T) | 12 | |

| Punch Press | 50 | |

| Roll Forging | 1 | |

| Heat Treatment and Surface Treatment | Quenching Furnace | 1 |

| Ageing Furnace | 2 | |

| Pickling Line | 2 | |

| Polishing Line | 2 | |

| Sandblasting Line | 3 | |

| Machining | Three-Axis Machining Center | 20 |

| Four-Axis Machining Center | 23 | |

| Drilling and Milling Center | 6 | |

| Drilling Machine | 26 | |

| Honing Machine | 2 | |

| Ultrasonic Cleaning | 2 | |

| Broaching Machine | 1 | |

| Testing Equipment | Coordinate Measuring Machine (CMM) | 1 |

| Spectrometer | 1 | |

| Material Tensile Testing Machine | 2 | |

| Hardness Tester | 4 | |

| Profilometer | 1 | |

| Fluorescent Penetrant Inspection Line | 1 |

What is Forging

Forging is a processing method that presses the metal by hammering or pressing to make it plastically deformed, so as to change the lattice arrangement of the metal, reduce the internal voids, eliminate defects, and improve the strength, toughness and other mechanical properties of the metal. According to the processing method, it can be divided into the following three types:

- Open Forging: Without using a die, the metal is repeatedly hammered to deform it, which is suitable for forging blanks of non-standard large parts.

- Die forging: The metal is pressed into the die by pressure, which has high production efficiency and is used to produce complex shape parts.

- Roll forging: Using the fan-shaped die on a pair of counter-rotating rolls, the metal blank is rolled in multiple passes, and gradually rolled into a forging of the desired shape. It is suitable for forging shafts or flat forgings.

Advantages of Forging

The main advantages of forging compared with other metal processing processes are reflected in the following aspects:

- Excellent mechanical properties

- Near-net shaped, high material utilization

- High consistency, suitable for mass production

Any processing method has its drawbacks, and forging is no exception. Its disadvantages are mainly reflected in the high cost of tooling (especially die forging) and the low precision, which often requires additional machining for high-precision applications.

FAQs

Do you support low-volume orders?

Yes, we have the ability to design and manufacture the mold according to your drawing or sample.

What is the customization process?

Yes, we have multiple automation forging production lines and can handle over 50T forgings a month.

Can HDC perform precision machining on forgings?

Yes, with over 40 3-axis and 4-axis machining centers, we can perform precision machining on forgings.

Do I need to pay for the mold?

Yes, the mold fee is needed. However, if the order meets our requirements, the mold fee can be refunded.

Does HDC offers after sales service?

We take responsibility for all quality issues caused by materials or forging processes and provide free rework services.

How do I pay for the order?

For more information, please the this link for details.

Get Your Custom Quote Today

Ready to discuss your forging requirements? Our engineering team is standing by to provide expert consultation and competitive pricing.

Request Free Quote