Rapid Prototyping Services

Welcome to HDC Manufacturing’s Rapid Prototyping Services. Transform your ideas into precise, tangible models quickly and efficiently. Our advanced technology and expertise support various industries, including automotive, aerospace, medical, and consumer products. With HDC, reduce time-to-market, enhance design quality, and achieve your project goals with confidence.

Advantages of Rapid Prototyping

Discover the key benefits of using rapid prototyping for your product development needs.

Speed and Efficiency

Rapidly transform designs into physical models, significantly reducing the time from concept to prototype. This accelerates the overall product development process and enables quicker decision-making.

Cost-Effective

Lower production costs by minimizing material waste and reducing the need for expensive tooling. This makes rapid prototyping an economical choice for testing multiple iterations without incurring high costs.

Design Validation

Test and validate design concepts early in the development process. Rapid prototyping allows for quick iterations and improvements, ensuring that the final product meets all specifications and requirements.

Improved Communication

Enhance communication with stakeholders by providing tangible prototypes that clearly demonstrate design intent and functionality. This leads to better collaboration and understanding among team members, clients, and manufacturers.

Customization and Flexibility

Easily modify prototypes to accommodate design changes, enabling greater flexibility and customization. This adaptability allows for the exploration of various design alternatives and innovative solutions.

Risk Reduction

Identify and address potential design flaws early, reducing the risk of costly revisions during later stages of production. By catching issues early, rapid prototyping helps ensure a smoother transition to full-scale manufacturing.

Why Choose HDC Manufacturing

HDC Manufacturing offers a wide range of advanced processing technologies, including 3D printing, CNC machining, and injection molding, ensuring the most suitable method for your project needs. We prioritize both speed and precision, delivering high-quality prototypes quickly without compromising on accuracy. Our extensive selection of materials, including plastics, metals, and composites, ensures that your prototypes closely mimic the final production product in terms of appearance, functionality, and performance.

Our production-ready prototypes facilitate a seamless transition to full-scale manufacturing, saving you time and resources. Our experienced team provides comprehensive design assistance to refine and improve your designs during the prototyping phase, ensuring the final product meets all requirements. At HDC, we prioritize customer satisfaction, working closely with you throughout the entire process, and implementing stringent quality control measures to ensure each prototype meets your exact specifications. Choose HDC for cutting-edge technology, expert design support, and unparalleled customer service.

Materials for Rapid Prototyping

Explore the diverse range of materials HDC Manufacturing offers for rapid prototyping and their suitable processing technologies to meet your project’s specific needs.

Stainless Steel

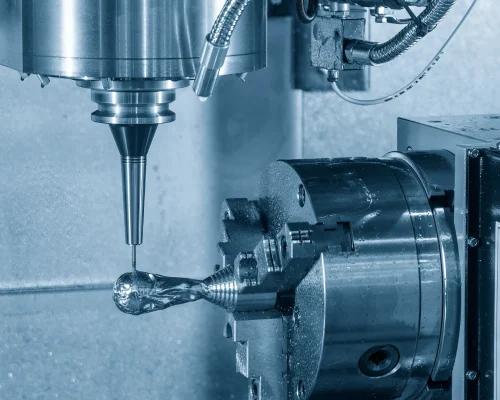

Used for robust prototypes in medical devices, tools, and structural components, stainless steel offers excellent strength and corrosion resistance. It is best processed using CNC machining, allowing for high-precision and durable prototypes.

Aluminum Alloy

Lightweight and strong, aluminum is used for functional prototypes in aerospace, automotive, and industrial applications. It can be processed through CNC machining, providing high-quality, detailed prototypes that are both durable and precise.

Nylon (Polyamide)

Polycarbonate (PC)

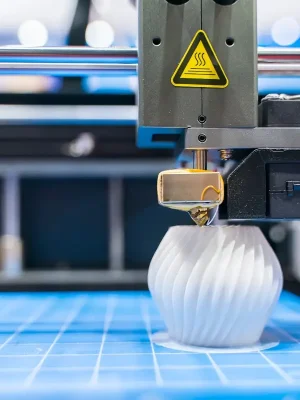

With high impact resistance and transparency, polycarbonate is ideal for prototypes requiring clear, strong components like light covers and lenses. It is suitable for 3D printing and injection molding, ensuring robust and precise prototypes.

Titanium Alloy

Known for its exceptional strength-to-weight ratio and biocompatibility, titanium is suitable for aerospace components, medical implants, and high-performance parts. It is best processed using CNC machining, ensuring strong and precise prototypes.

Understanding Rapid Prototyping

Learn about the concept of rapid prototyping and the various technologies that enable fast and efficient product development.

Rapid prototyping is a group of techniques used to quickly fabricate a physical part or assembly using three-dimensional computer-aided design (CAD) data. The primary objective of rapid prototyping is to accelerate the product development process, allowing for quick iterations, design validation, and functional testing before full-scale production. It plays a crucial role in reducing development time and costs while improving the final product’s quality and performance.

Key Rapid Prototyping Technologies:

- 3D Printing (Additive Manufacturing): Creates objects layer by layer from digital models, ideal for complex geometries and intricate details. Common technologies include FDM for thermoplastics, SLA for detailed resin parts, and SLS for strong powdered material structures.

- CNC Machining: A subtractive process using computer-controlled tools to remove material from a solid block. This method, known as CNC rapid prototyping, is suitable for creating high-precision parts and prototypes from metals, plastics, and composites, offering quick turnaround times for accurate and reliable prototypes.

- Vacuum Casting: Uses silicone molds to produce small series of high-quality plastic prototypes with excellent surface finishes. Suitable for producing small batches of complex and intricate designs.

- Sheet Metal Prototyping: Involves cutting, bending, and assembling sheet metal to create functional prototypes and parts, essential for testing metal components. Used in automotive, aerospace, and industrial applications.

Future Trends in Rapid Prototyping:

Emerging technologies such as 4D printing, bioprinting, and new composite materials are expanding the possibilities of rapid prototyping, promising greater flexibility, functionality, and application scope across various industries. Additionally, there is a growing focus on sustainability, with initiatives aimed at developing biodegradable materials, recycling prototype waste, and implementing energy-efficient manufacturing processes to minimize environmental impact. These advancements, coupled with innovations in CNC rapid prototyping, are set to enhance the effectiveness and reach of rapid prototyping in modern manufacturing.

Applications of Rapid Prototyping

Automotive Industry

In the automotive industry, rapid prototyping is used to develop prototypes for vehicle parts such as engine components, interior features, and body panels. This helps improve design aesthetics, performance, and safety by allowing for thorough testing and iteration before mass production.

Aerospace Industry

Rapid prototyping is essential in aerospace for creating complex components like turbine blades, engine parts, and airframe structures. It allows for precise validation of designs, material testing, and functionality assessment in high-stress and high-temperature environments, accelerating innovation and enhancing safety.

Medical Industry

Rapid prototyping plays a critical role in developing medical devices, surgical instruments, and custom prosthetics. It enables the production of highly precise and biocompatible parts tailored to individual patient needs, enhancing the effectiveness of medical treatments and surgical procedures.

Industrial Manufacturing

In industrial manufacturing, rapid prototyping helps produce custom tools, machine parts, and fixtures. It enables quick iterations and modifications, improving production efficiency, reducing downtime, and allowing for the rapid deployment of new manufacturing solutions.

Architecture and Construction

Rapid prototyping is used to create detailed architectural models and prototypes, aiding in visualization, planning, and presentation. It helps architects and construction professionals explore design possibilities, test structural integrity, and communicate ideas effectively to clients and stakeholders.

Consumer Electronics

The consumer electronics industry benefits from rapid prototyping by creating prototypes for gadgets and devices like smartphones, wearables, and home appliances. This facilitates design validation, ergonomic testing, and functional evaluation, ensuring products meet high standards before market release.

Entertainment and Animation

In the entertainment and animation sectors, rapid prototyping is employed to produce models, props, and characters for movies, games, and animations. It enhances creativity and realism, enabling artists and designers to bring their visions to life with high precision and detail.

Future Trends and Innovations in Rapid Prototyping

Explore the cutting-edge advancements and future trends shaping the field of rapid prototyping.

The future of rapid prototyping is marked by exciting advancements such as 4D printing, where materials change shape or properties in response to environmental stimuli, and bioprinting, which layers living cells to create tissues and organs for medical applications.

The development of advanced materials with enhanced properties like greater strength, flexibility, and heat resistance, along with the integration of AI and machine learning for optimized designs, are significantly expanding the capabilities of rapid prototyping. Hybrid manufacturing techniques that combine additive and subtractive methods offer the best of both worlds, enabling the production of complex geometries with high precision and superior surface finishes.

Additionally, there is a growing focus on sustainability, driving the development of eco-friendly materials and energy-efficient prototyping methods. Enhanced simulation and virtual prototyping software are further refining the design process, reducing the need for physical prototypes and allowing for more detailed and accurate performance testing. These innovations promise to make rapid prototyping faster, more efficient, and more versatile, revolutionizing product development across various industries, from aerospace and automotive to healthcare and consumer electronics.

FAQs

What is the typical lead time for a rapid prototyping project?

The lead time for a rapid prototyping project typically ranges from a few days to a few weeks, depending on the complexity of the design and the chosen manufacturing method.

What materials can be used for rapid prototyping?

We offer a wide range of materials including plastics (ABS, PLA, Nylon), metals (aluminum, stainless steel, titanium), and resins. The choice of material depends on the specific requirements of your prototype.

How accurate are the prototypes produced through rapid prototyping?

The accuracy of rapid prototypes can be very high, often within ±0.1mm, depending on the technology used. 3D printing, CNC machining, and other methods can achieve fine details and tight tolerances.

Can rapid prototyping be used for functional testing?

Yes, rapid prototyping is ideal for functional testing. It allows you to test the design, fit, and functionality of your prototype before proceeding to full-scale production.

What are the cost considerations for rapid prototyping?

Costs vary based on the complexity of the design, the material used, and the manufacturing method. Rapid prototyping is generally cost-effective for small batches and iterative testing, helping to save costs in the long run by identifying and resolving design issues early.

Do you provide design assistance during the prototyping process?

Yes, we offer comprehensive design support to help refine and optimize your prototypes. Our experienced team can assist with CAD modeling, material selection, and iterative improvements.

What file formats do you accept for 3D models?

We accept a variety of 3D file formats including STL, OBJ, STEP, and IGES. Please ensure your files are properly scaled and detailed to facilitate the prototyping process.

Can you handle large or complex projects?

Absolutely. We have the capabilities to handle projects of varying sizes and complexities. Our advanced equipment and skilled team ensure high-quality results for both simple and intricate designs.

How do you ensure the quality of the prototypes?

We implement stringent quality control measures throughout the prototyping process. Each prototype undergoes thorough inspection and testing to ensure it meets your exact specifications and standards.

What post-processing options are available for prototypes?

We offer various post-processing services including sanding, polishing, painting, and coating to enhance the appearance and functionality of your prototypes.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Request Free Quote

More Solutions

Explore the range of additional services HDC Manufacturing offers, from custom design and prototyping to logistics and post-manufacturing support.

Known for its strength, flexibility, and durability, nylon is used in functional prototypes, gears, and mechanical parts requiring high wear resistance. It can be effectively processed using both 3D printing and CNC machining, offering versatility in application.