- بيت

- Capabilities

- Sheet Metal Fabrication Service

Expert Sheet Metal Fabrication Services at HDC

Discover how HDC’s sheet metal fabrication services can elevate your project with custom precision cuts, bends, and finishes tailored to meet diverse industry standards and requirements.

Why Choose HDC for Sheet Metal Fabrication Service

Explore the benefits of leveraging HDC’s sheet metal fabrication to enhance your manufacturing processes, ensuring quality and efficiency.

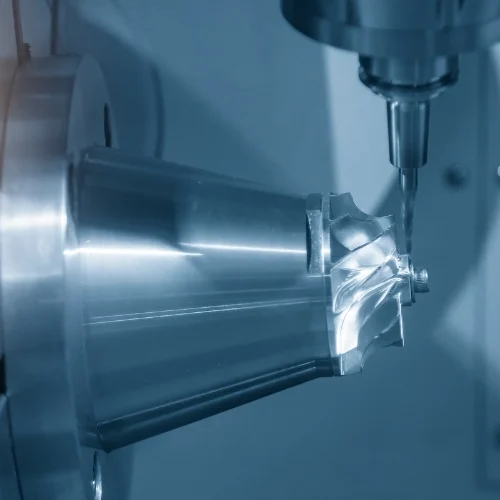

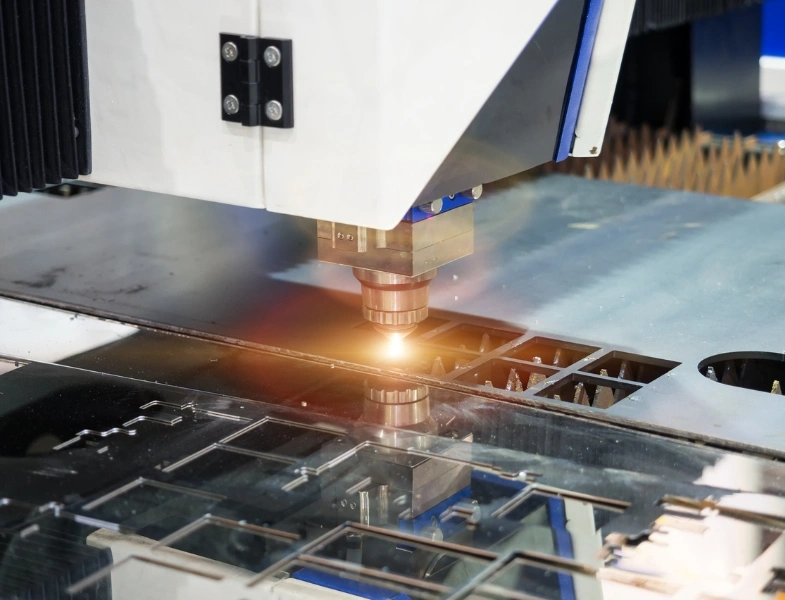

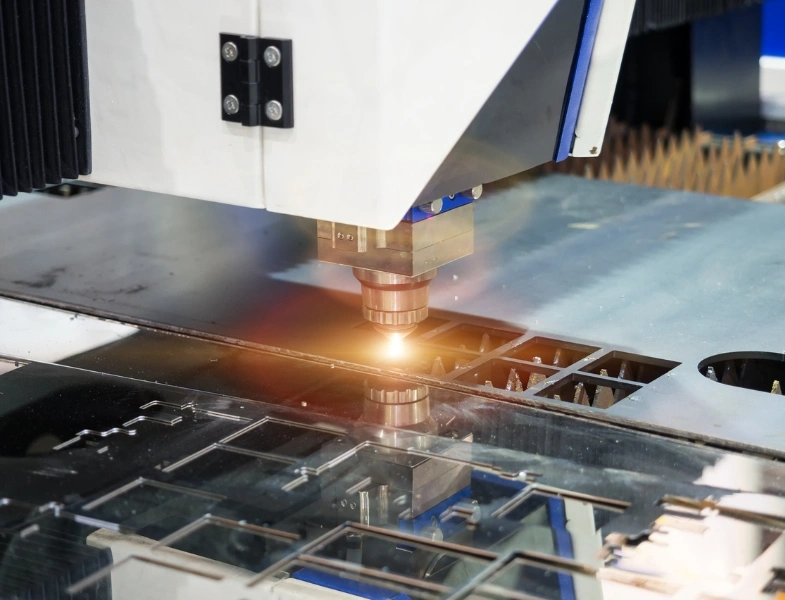

Our Metal Fabrication Capabilities

HDC provides a comprehensive range of metal fabrication services, including welding, laser cutting, water jet cutting, metal bending, metal stamping, and metal punching. Discover how our capabilities can enhance your projects.

Welding

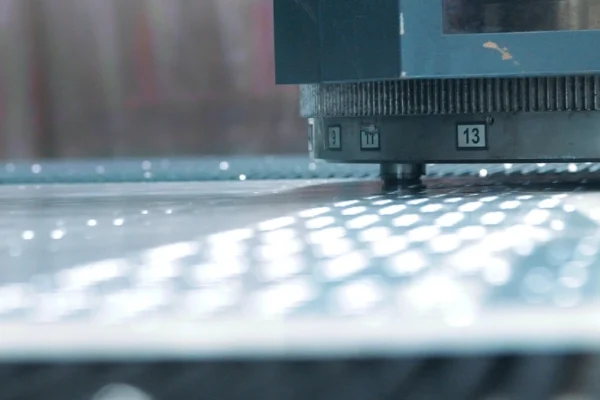

Water Jet Cutting

Material Selection for Sheet Metal Fabrication at HDC

HDC’s commitment to offering a diverse range of materials in specific grades ensures that you can find the right fit for your sheet metal fabrication projects.

Brass

Brass offers a beautiful finish and is often used in decorative components, plumbing fittings, and electrical applications due to its conductivity and aesthetic appeal. We offers C36000 and C26000 brass grades, which are ideal for intricate designs and polished finishes. Its natural resistance to corrosion makes brass suitable for both indoor and outdoor applications, ensuring longevity and durability.

Stainless Steel

Our stainless steel options are perfect for demanding environments, offering durability and a sleek finish that is easy to maintain. We provides various grades, including 304 and 316 stainless steel. Grade 304 is versatile for general use, while 316 is ideal for marine and chemical environments due to its enhanced corrosion resistance. This makes it suitable for food processing, medical equipment, and construction.

Aluminum

Aluminum and it’s alloys are ideal for applications requiring weight reduction without sacrificing strength, making it popular in the automotive and aerospace industries. Our aluminum offerings include 6061 and 5052 grades. Grade 6061 is known for its strength and machinability, while 5052 is more ductile and resistant to corrosion, making both grades suitable for a variety of projects.

Carbon Steel

HDC offers various carbon steel grades, providing excellent toughness and wear resistance, making it suitable for structural and heavy-duty components. We provide grades such as A36 and A572. Grade A36 is a common structural steel that offers good weldability, while A572 is designed for high-strength applications, making them suitable for construction, machinery, and automotive components.

Exploring Sheet Metal Fabrication

Delve into the intricate world of sheet metal fabrication, understanding its processes, techniques, and the diverse applications it supports in various industries.

Sheet metal fabrication involves transforming flat sheets of metal into desired shapes and forms through various techniques. This versatile process is crucial for manufacturing components across industries.

Let’s explore the key processes involved in sheet metal fabrication and their applications.

1. Cutting: Transforms flat sheets of metal into desired shapes.

- Laser Cutting: Offers high precision and intricate designs.

- Water Jet Cutting: Ideal for thicker materials, avoids heat distortion.

- Mechanical Cutting: Suitable for high-volume production.

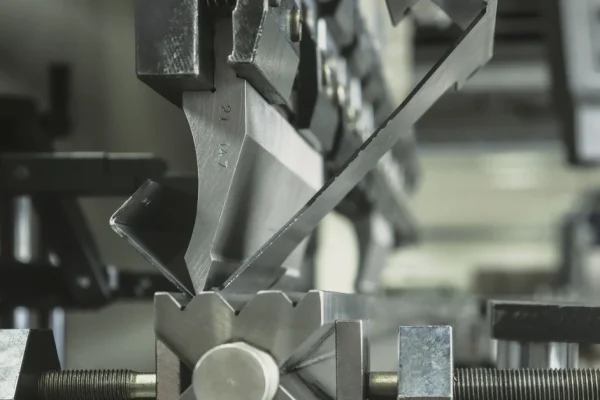

2. Bending: Shapes metal sheets into specific angles and forms.

- Air Bending: Uses a punch and die to create angles.

- Bottom Bending: Provides more precise control for tight tolerances.

3. Welding: Joins multiple metal pieces to form a cohesive structure.

- MIG Welding (Metal Inert Gas): Efficient for thicker materials.

- TIG Welding (Tungsten Inert Gas): Ideal for high-precision applications.

Diverse Applications of Sheet Metal Fabrication

Explore the broad range of industries leveraging sheet metal fabrication, showcasing how this versatile process supports various sector-specific requirements.

Automotive

Aerospace

Construction

Electronics

Energy

Medical

Precision in Sheet Metal Fabrication at HDC

Discover the high levels of accuracy achievable with HDC’s sheet metal fabrication, ensuring your components meet stringent precision standards.

| Feature | Typical Tolerance | Precision Details |

|---|---|---|

| General Dimensions | ±0.010 inches | Standard tolerance for general features and outlines. |

| Critical Dimensions | ±0.005 inches | Enhanced precision for critical dimensions in specialized applications. |

| Bending Angles | ±0.5 degrees | High accuracy in bending angles, crucial for assembly fitting. |

| Hole Diameter | ±0.005 inches | Precision in hole diameters, important for fastening and alignment features. |

| Edge Finish | Up to 32 microinches | Achieving smooth edge finishes for aesthetic and functional requirements. |

Sheet Metal Fabrication FAQs at HDC

Get answers to common questions about customizing Swiss screw machined parts to ensure your project meets exact specifications.

HDC works with a variety of metals including stainless steel, aluminum, carbon steel, copper, and brass, allowing us to meet a wide range of application requirements.

We can handle sheet metal thicknesses up to 0.5 inches, depending on the metal type and the specific fabrication process used.

Yes, our team offers full support from the design phase to the final production. We help optimize designs for manufacturability and cost-effectiveness.

We typically achieve tolerances within ±0.010 inches for general features, though tighter tolerances can be managed depending on the project specifics.

We adhere to strict quality control standards with comprehensive inspections throughout the fabrication process to ensure each part meets both our standards and customer expectations.

We provide a range of finishing options including powder coating, painting, galvanizing, and anodizing to enhance the appearance and durability of the final products.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry