- بيت

- Capabilities

- Water Jet Cutting Service

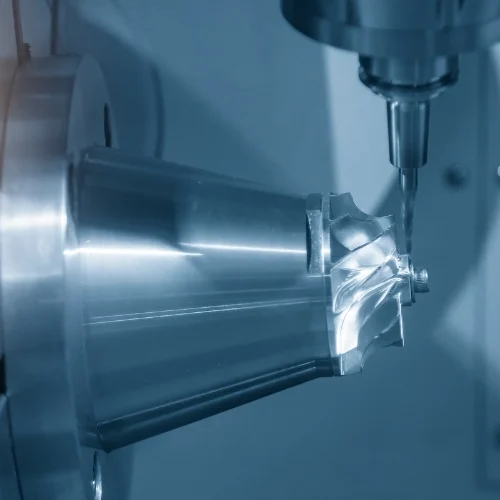

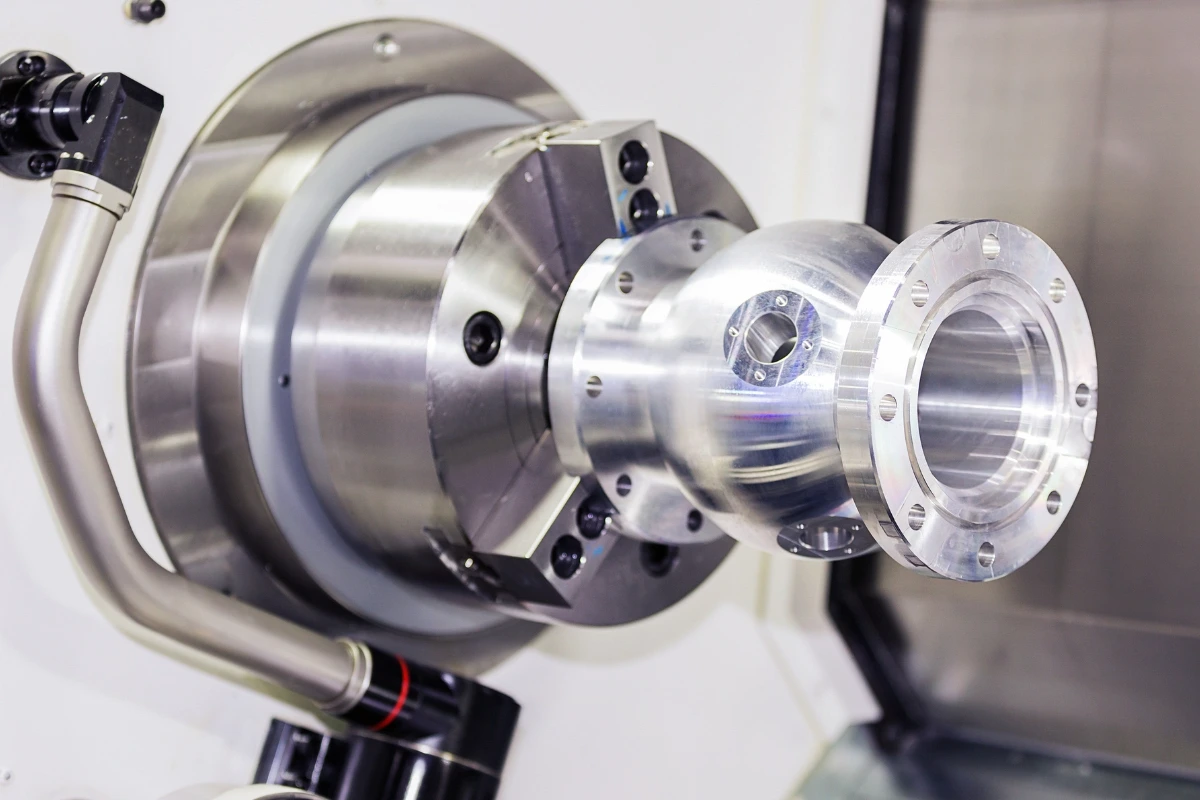

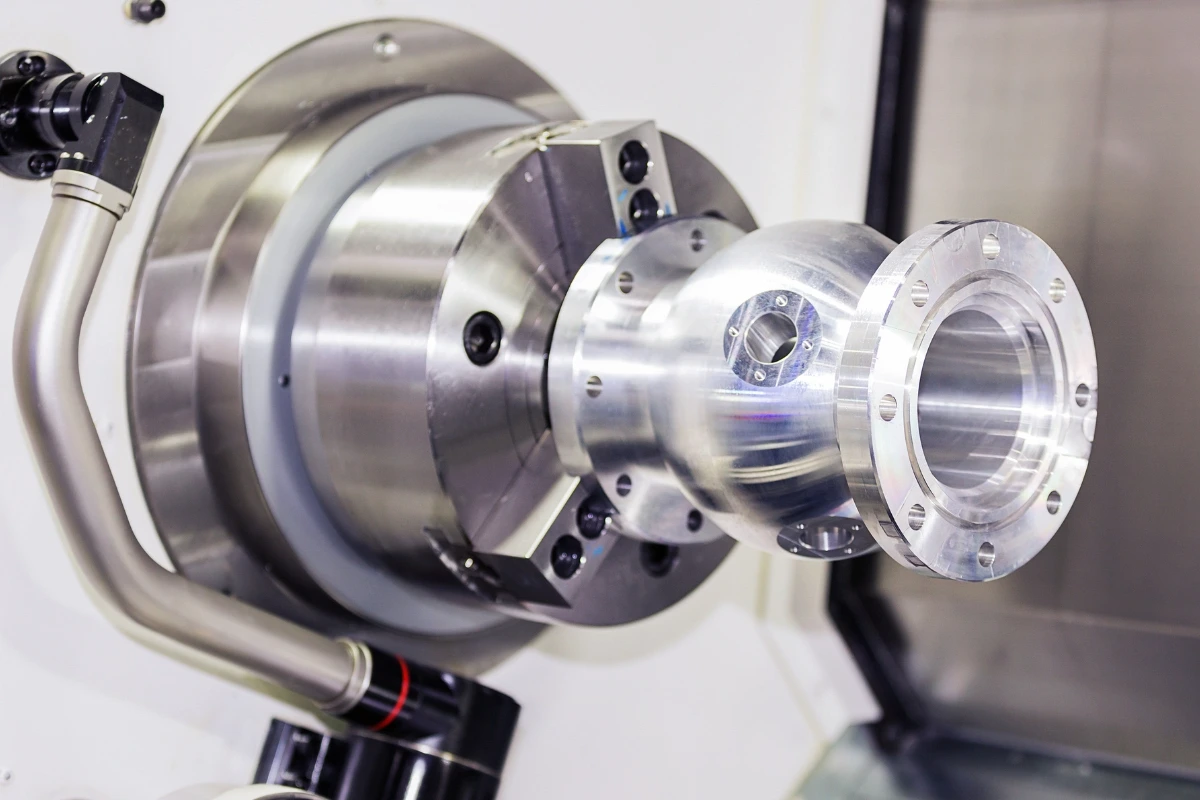

Cutting-Edge Water Jet Services for Custom Solutions

Water jet cutting is a revolutionary method that combines high-pressure water with abrasive materials to deliver unparalleled precision and versatility. At HDC, we harness this technology to transform your ideas into reality, ensuring top-quality results for a variety of applications.

Why Choose Water Jet Cutting

Water jet cutting is a fantastic way to get precise cuts on all sorts of materials, like metal, plastic, glass, and stone. It’s perfect for those tricky designs and complex shapes you might have in mind. What’s really great about this method is that it’s eco-friendly—there’s hardly any waste, and it doesn’t use harsh chemicals. Plus, because it generates very little heat, you won’t have to worry about your materials getting warped or damaged.

Choosing water jet cutting means you’re going for a versatile and accurate solution that suits a variety of projects. At HDC, we use this innovative technology to deliver top-notch results that are tailored to your needs.

Advantages of HDC Water Jet Cutting Service

Materials We Work With Water Jet Cutting

Learn about the diverse materials we process with water jet cutting and their specific applications in various industries.

Titanium

Valued for its lightweight yet incredibly strong properties, titanium is suitable for high-performance applications in aerospace and medical fields. HDC provides titanium in grades such as Ti-6Al-4V and CP Grade 2, meeting stringent industry specifications.

Aluminum

Lightweight and versatile, aluminum is easy to machine, making it ideal for automotive parts, frames, and enclosures. HDC works with aluminum grades like 6061, 5052, and 7075 to cater to various application needs.

Stainless Steel

Known for its excellent corrosion resistance, stainless steel is perfect for applications requiring hygiene and durability. Common uses include food processing equipment and decorative panels, available in grades like 304, 316, and 430.

Steel

Strong and cost-effective, steel is ideal for structural components like beams and brackets. HDC offers high-quality steel in grades such as ASTM A36 and ASTM A992, ensuring a perfect fit for your project.

Composite Materials

Offering a high strength-to-weight ratio, composite materials are perfect for applications like carbon fiber automotive parts and fiberglass marine components. HDC provides various grades tailored to specific composite formulations.

Custom Water Jet Cutting Service Process

Understand our streamlined process, ensuring efficiency and quality from initial consultation to final delivery.

1. Start the Conversation

2. Review Your Design

3. Select Your Material

4. Prepare the Machine

5. Cutting Time

6. Quality Check

7. Finishing Touches

8. Get It to You

Industries We Serve

Find out how our water jet cutting services cater to multiple sectors, enhancing productivity and innovation.

Automotive

Aerospace

Medical

Manufacturing

Marine

Architecture

Precision and Accuracy of Water Jet Cutting

Delve into the accuracy of our water jet cutting technology and its importance for high-quality outcomes.

| Accuracy Level | Material Types | Applications |

| ±0.001 inches | Metals (steel, aluminum) | Aerospace components, automotive parts |

| ±0.001 inches | Glass and ceramics | Decorative glass, tiles |

| ±0.001 inches | Plastics (acrylic, PVC) | Signage, prototypes |

| ±0.001 inches | Composites (carbon fiber) | Sporting goods, automotive components |

Frequently Asked Questions

Get answers to common inquiries about our water jet cutting services, addressing customer concerns and clarifications.

We can work with a variety of materials, including steel, stainless steel, aluminum, titanium, and even some composites. Each material has its own benefits, making it suitable for different projects.

Our water jet machines can handle materials up to about 8 inches thick. The specific thickness may vary based on the material and your particular needs.

We aim for high precision in our cuts, usually reaching tolerances of ±0.002 to ±0.005 inches. This helps ensure that everything fits together as it should.

Water jet cutting produces less heat compared to laser or plasma cutting, which means less warping and cleaner edges. It’s especially effective for thicker materials.

Lead times can vary based on how complex your project is and how many parts you need. We always strive to deliver as quickly as possible while maintaining quality.

Absolutely! We love working on custom designs. Just send us your drawings or ideas, and we’ll provide a personalized quote.

Request a Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry