- بيت

- Capabilities

- 3D Printing Service

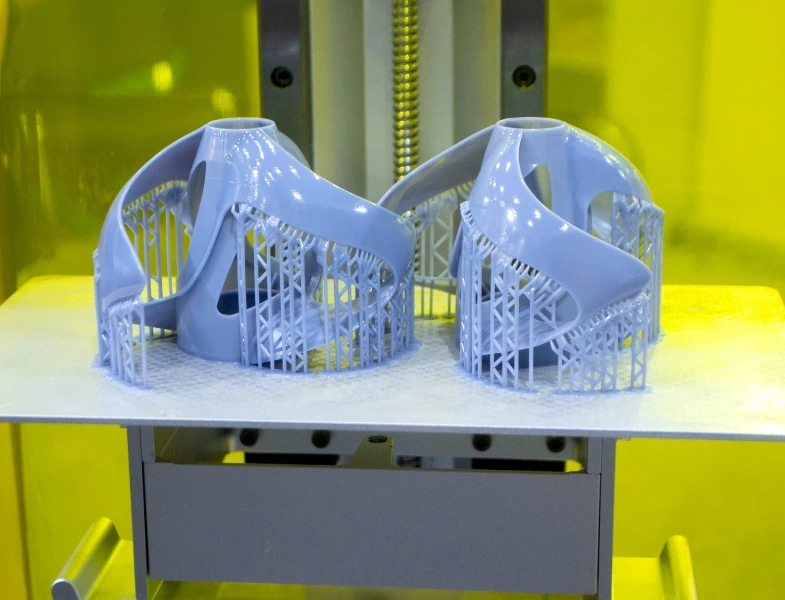

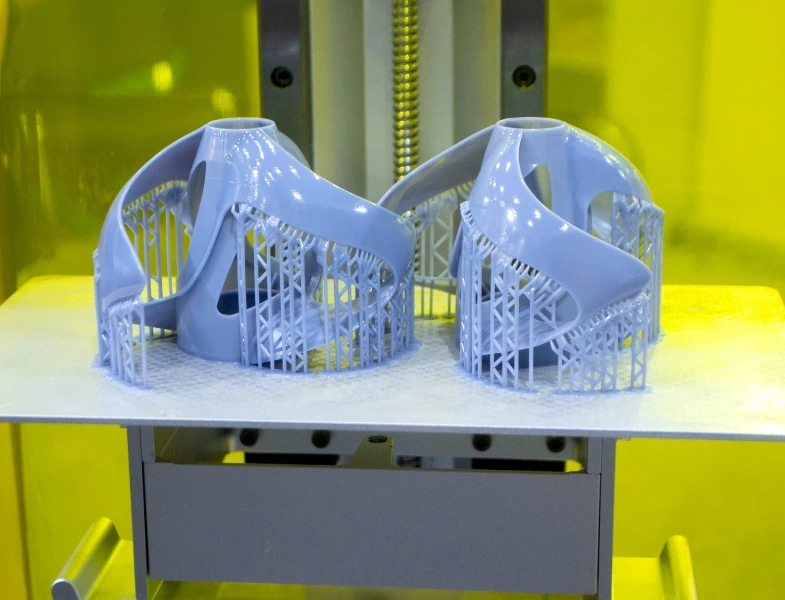

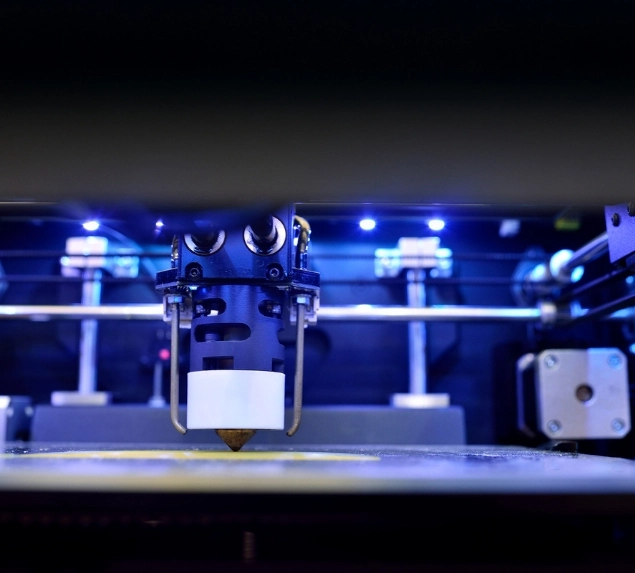

High-Quality 3D Printing Services by HDC

Discover HDC Manufacturing's advanced 3D printing services, designed to transform your ideas into reality with unmatched precision and innovation. Leveraging cutting-edge technology and a team of industry experts, we deliver high-quality 3D printing solutions for prototyping, custom parts, and full-scale production.

Advantages of 3D Printing Technology

Discover how HDC's 3D printing technology can solve your challenges—faster prototyping, lower costs, and sustainable production.

Rapid Prototyping

1. Reduce development time and costs.

2. Test and refine designs faster.

3. Ideal for aerospace, medical, and automotive industries.

Rapid Prototyping

1. Produce complex, intricate designs.

2. No limits to creativity or innovation.

3. Perfect for custom components and detailed models.

Cost Efficiency

1. Minimize material waste.

2. No need for expensive molds or tooling.

3. Best for small-batch and custom projects.

Customization

1. Personalize products for higher satisfaction.

2. Ideal for medical implants, automotive parts, and more.

3. Deliver precision and reliability.

Reduced Lead Times

1. Streamline production processes.

2. Eliminate traditional manufacturing steps.

3. From prototyping to full-scale production, we’ve got you covered.

Sustainability

1. Use sustainable materials.

2. Reduce carbon footprint and waste.

3. Support your green initiatives with our technology.

Why Choose HDC for Your 3D Printing Needs

State-of-the-Art Technology

Latest 3D printing equipment and software.

Expert Team

Skilled professionals with industry expertise.

Wide Range of Materials

Plastics, composites, and metals available.

Customization and Flexibility

Tailored solutions for unique requirements.

Comprehensive Support

End-to-end service from consultation to delivery.

Competitive Pricing

Top-tier services at affordable rates.

Material Selection for Sheet Metal Fabrication

Explore HDC's wide range of materials for sheet metal fabrication and CNC machining, designed to meet your precision manufacturing needs.

ABS

Properties: High strength, durability, and impact resistance.

Applications: Functional prototypes, automotive parts, and household appliances.

Benefits: Resistant to high temperatures, ideal for demanding environments.

Nylon

Properties: Strong, flexible, and wear-resistant.

Applications: Functional parts, gears, and tools.

Benefits: Excellent for engineering applications requiring durability and abrasion resistance.

Polycarbonate

Properties: High impact strength and transparency.

Applications: Protective covers, lenses, and electronic components.

Benefits: Lightweight and shatter-resistant, perfect for safety-critical applications.

Aluminum Alloy

Properties: Lightweight, strong, and corrosion-resistant.

Applications: Aerospace components, automotive parts, and consumer electronics.

Benefits: Ideal for weight-sensitive applications, with excellent machinability.

Stainless Steel

Properties: High strength, corrosion resistance, and durability.

Applications: Medical devices, food processing equipment, and industrial machinery.

Benefits: Suitable for harsh environments and high-stress applications.

Titanium Alloy

Properties: High strength-to-weight ratio, corrosion resistance, and biocompatibility.

Applications: Aerospace components, medical implants, and marine equipment.

Benefits: Perfect for extreme conditions and high-performance applications.

Understanding 3D Printing Technology

Discover how 3D printing, also known as additive manufacturing, is revolutionizing industries by creating complex, customized objects with precision and efficiency.

3D printing, or additive manufacturing, is the process of creating three-dimensional objects from a digital file. By layering materials such as plastics, resins, or composites, 3D printers build objects with high precision and efficiency.

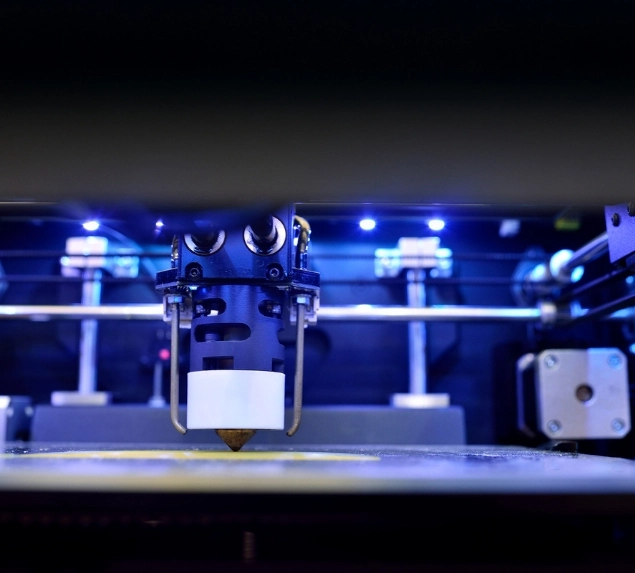

The 3D Printing Process

1. Design: Create a digital model using CAD software.

2. Slice: Software divides the model into thin layers.

3. Print: The 3D printer builds the object layer by layer.

Types of 3D Printing Technologies

- Fused Deposition Modeling (FDM): Thermoplastic filaments are heated and extruded to create objects. Ideal for prototyping and functional parts.

- Stereolithography (SLA): A laser cures liquid resin into hardened plastic, known for high precision and smooth finishes.

- Selective Laser Sintering (SLS): A laser fuses powdered material (e.g., nylon) into solid structures, perfect for complex geometries and functional parts.

Common Challenges and Solutions

- Material Limitations: Ongoing research expands material options for diverse applications.

- Surface Finish: Post-processing (e.g., sanding, polishing) improves appearance and functionality.

- Size Constraints: Large objects can be printed in sections and assembled.

- Accuracy and Precision: Regular calibration ensures consistent quality.

The Future of 3D Printing

As technology advances, 3D printing will play a key role in sustainable manufacturing and the production of smart, interconnected devices. Innovations in materials, speed, and build volume will drive its adoption across industries.

Applications of 3D Printing Across Various Industries

Discover how 3D printing is transforming industries with innovative solutions, enhanced efficiency, and unparalleled design possibilities.

Automotive Industry

▪️Custom Performance Parts: Create tailored components for enhanced vehicle performance.

▪️Rapid Tooling: Streamline manufacturing with fast production of tools and fixtures.

▪️Prototyping: Test and iterate new designs quickly and cost-effectively.

Aerospace Industry

▪️Lightweight Components: Produce strong, lightweight parts to reduce aircraft weight and improve fuel efficiency.

▪️Complex Geometries: Manufacture intricate parts that are difficult or impossible with traditional methods.

▪️Faster Development: Accelerate the design and testing of new aerospace components.

Medical Industry

▪️Custom Prosthetics and Implants: Improve patient comfort and functionality with personalized medical devices.

▪️Anatomical Models: Create detailed models for surgical planning and medical education.

▪️Bioprinting: Explore the future of tissue and organ printing for advanced medical solutions.

Electronics Industry

▪️Rapid Prototyping: Develop and test components and enclosures quickly.

▪️Custom Housings: Design unique device housings for specialized applications.

▪️Printed Circuit Boards (PCBs): Explore the potential for 3D-printed electronics.

Automotive Industry

▪️Architectural Models: Create detailed models for visualization and planning.

▪️Custom Components: Fabricate unique building elements with precision.

▪️Large-Scale Printing: Explore the potential for printing entire structures or large components.

Automotive Industry

▪️Personalized Products: Produce custom jewelry, phone cases, and home decor.

▪️Rapid Design Iteration: Quickly refine product designs for faster market entry.

▪️Small Batch Production: Cost-effectively cater to niche markets and startups.

Precision of 3D Printing Technology

3D printing technology offers exceptional precision, allowing for the creation of highly detailed and accurate parts.

| Technology | Layer Resolution | Dimensional Accuracy | Surface Finish |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | 100-400 microns | ± 0.5% (lower precision) | Moderate to rough |

| Stereolithography (SLA) | 25-100 microns | ± 0.1% (high precision) | Smooth to very smooth |

| Selective Laser Sintering (SLS) | 60-150 microns | ± 0.3% (medium precision) | Moderate |

| Digital Light Processing (DLP) | 25-100 microns | ± 0.1% (high precision) | Smooth to very smooth |

| Multi Jet Fusion (MJF) | 80-100 microns | ± 0.3% (medium precision) | Moderate |

| PolyJet | 16-30 microns | ± 0.1% (high precision) | Very smooth |

3D Printing FAQs at HDC

We accept STL, OBJ, and STEP file formats for 3D printing. Ensure your files are properly formatted and scaled for the best results.

Lead times vary depending on the project's complexity and volume, but most orders are completed within 6-8 weeks.

We offer a wide range of materials, including PLA, ABS, PETG, Nylon, PVA, Polycarbonate, and TPE.

Yes, we offer various post-processing services such as sanding, polishing, painting, and assembly to enhance the final appearance and functionality of your parts.

Our printers can accommodate parts up to 300 x 300 x 400 mm. For larger projects, we can print in sections and assemble them.

We use state-of-the-art equipment and conduct rigorous quality control checks at each stage of the printing process to ensure high-quality results.

Costs vary based on factors such as material, print time, and post-processing. Contact us for a detailed quote based on your project requirements.

Absolutely. We offer prototype services so you can test and refine your design before proceeding with full-scale production.

You can place an order by contacting us through our website or by calling our customer service team. Provide your design files and project details, and we will guide you through the process.

Get an Instant Quote!

Get a quick quote for your project with just a click! Request an instant quote now!

Contact With Us

for any inquiry