Closed Die forging vs. Open Die forging are metal forging...

Expert Global Stainless Steel Forging Service

Advanced forging capabilities from 160T to 4000T capacity. Precision-engineered stainless steel components for global industries with comprehensive quality assurance.

- International Certified

- Global Shipping

- Custom Solution

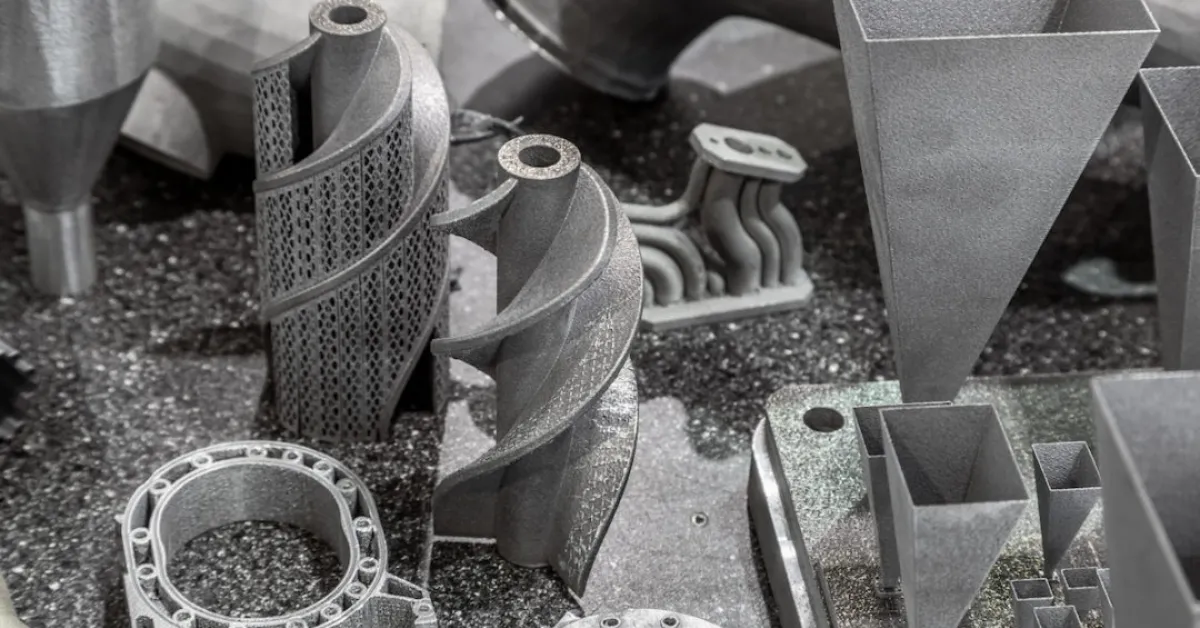

Our Forging Services

Comprehensive service from forging to post processing for industry applications

Die Forging

Precision die forging with near-net shape

- Forging Presses from 160T to 4000T

- 100 kg stainless steel parts forging capability

- Reduce material waste and post-processing

- Excellent strength for critical applications

Learn More

CNC Post Finishing

Post-process with the advanced CNC machine combine strength and precision

- 4-axis and 5-axis CNC pots finishing available

- 0.05 mm tight tolerance is achievable

- Excellent dimensional accuracy and surface quality for high demand applications

Learn More

Heat Treatment

Improved mechanical properties by heat treatment processes like quenching, tempering, solution

- Improve the toughness, plasticity and fatigue strength of materials.

- Eliminate residual stress and improve dimensional stability

- Adjust hardness, strength, and toughness

Learn More

Materials & Surface Treatment

Wide range of stainless steel and surface treatments for various project requests

Stainless Steel

Surface Treatments

Pickling & Passivation

Removes impurities and promotes stable oxide layer formation.

CNC Finishing

CNC machining for tight tolerance and superior surface finish

Sand/Bead Blasting

Removes oxide layers, burrs, and provides a matte surface

Polishing

Remove processing marks and achieve a smooth mirror finish

Painting/Powder Coating

Provides decorative color and additional physical barrier protection

Need One-Stop Solutions?

Need custom stainless steel forgings for your project? First time to export from overseas? Know little about forging technology? HDC is here to solve all your problems with a one-stop solution tailored for your projects.

Industry We Serve

Oil & Gas

- High-pressure valve bodies

- Downhole tool components

- Wellhead equipment parts

- Flanges, Pipeline fittings

Aerospace

- Landing gear components

- Engine mounts

- Turbine discs

- Structural fittings

- Actuator parts

Automotive

- Turbocharger shafts

- Transmission gears

- Crankshafts

- Connecting rods

- Suspension components

Power Generation

- Turbine blades

- Generator shafts

- Valve stems

- Fasteners for high-temp applications

Heavy Machinery

- Hydraulic cylinder rods

- Gears

- Sprockets

- Shafts

- Excavator bucket teeth adapters

How Do We Ensure Quality & Tolerances

Certified by multiple international standards, we follow a strict quality control procedure to ensure every forging aligns with your project requirements and performs optimally in its location.

Quality Control Capabilities:

- Material chemical composition analysis

- Material mechanical property testing (Hardness, Tensile)

- Foring defects detection with fluorescent penetrant inspection

- Final product dimensional inspection (CMM)

Why Choose HDC

We support global industries with over 10 years expertise and high quality stainless steel forgings

Full Process Capability

- Source stainless steel from reliable supplier

- Material composition and mechanical properties inspection

- In-house mold design and manufacturing

- Comprehensive post-processing

Flexible Production

- 160T – 4000T forging press produces forgings from 100g to 50kg

- Flexible quantity from prototype to mass production

- Rapid production process modification

Global Service

- Multilingual technical support

- Supports trade terms such as FOB and DPP

- Global shipping and logistics(Sea, Air, Railway and Express)

- Deal with international quality standards

One-Stop Solutions

- Material selection and design support

- Mold development and continuous optimization

- Application-specific post-processing solution

More About HDC

Over 30,000 m² of facility and advanced forging and testing equipment bring forgings with unmatched quality

| Equipment | Quantity | |

|---|---|---|

| Forging | Electric screw press (160T-4000T) | 22 |

| Forging Press (160T-1000T) | 12 | |

| Punch Press | 50 | |

| Roll Forging | 1 | |

| Heat Treatment and Surface Treatment | Quenching Furnace | 1 |

| Ageing Furnace | 2 | |

| Pickling Line | 2 | |

| Polishing Line | 2 | |

| Sandblasting Line | 3 | |

| Machining | Three-Axis Machining Center | 20 |

| Four-Axis Machining Center | 23 | |

| Drilling and Milling Center | 6 | |

| Drilling Machine | 26 | |

| Honing Machine | 2 | |

| Ultrasonic Cleaning | 2 | |

| Broaching Machine | 1 | |

| Testing Equipment | Coordinate Measuring Machine (CMM) | 1 |

| Spectrometer | 1 | |

| Material Tensile Testing Machine | 2 | |

| Hardness Tester | 4 | |

| Profilometer | 1 | |

| Fluorescent Penetrant Inspection Line | 1 |

Forging Products

Benefits of Stainless Steel Forging

Forging is one of the oldest manufacturing processes, it involves applying pressure to heated metal to force it to undergo plastic deformation, thus achieving the desired shape.

Unlike casting, which has numerous variations and can adapt almost all metals, forging requires metals with excellent high-temperature formability, impurity content, and uniform grain structure.

Stainless steel has become a commonly used forging material because of its balanced performance, and the main advantages are reflected in the following aspects:

- Tough at high temperatures: It can withstand the high temperature and pressure of forging and is not easy to crack and deformed.

- Denser structure after forging: Forging eliminates internal defects and improves strength and corrosion resistance.

- Able to forge complex shapes: Good plasticity, suitable for forging precision or complex parts, saving materials.

How HDC Forge Stainless Steel

We forge stainless steel primarily by the closed die forging process. This method uses a precisely matched top and bottom mold. Heated metal is placed between them and squeezed under high pressure, forcing it to take the exact shape of the tool cavities. This produces near-net-shape parts that require minimal finishing, are very strong and durable, and have a tough internal structure.

FAQ

Yes, our engineering team assists in optimizing your design and provides actionable solutions, including CAD files and evaluation reports.

Yes, with the in-house 4-axis and 5-axis machining center and years of CNC expertise, we can easily manufacture die casting molds for any application.

Yes, all our materials are certified, and we can provide certifications upon your request.

Yes, but the specific quantity varies; we need to evaluate it based on certain aspects of your projects, such as size, material, and manufacturing difficulty. The typical MOQ is 100, with mold costs calculated separately.

Your dedicated sales staff will connect with you and report the accuracy of the project in real time according to your requirements.

Fill and submit the form below, provide the necessary information, including quantity, material, finish, and design files(CAD files, drawings, pictures, PDF). We will provide a comprehensive quote within 24 hours.

Ready to Start Your Project?

Get a competitive quote for your stainless steel forging requirements.

Request Free Quote

Resources

Comparison of Metal 3D Printing, Forging, and Investment Casting

Discover the differences between metal 3D printing, forging, and investment...

Metal Investment Casting vs. Metal Forging: 8 Things to Consider

Choosing between investment casting and forging depends on your specific...

Top 20 Aluminum Forging Manufacturers in China 2024

The following lists the top ten aluminum alloy forging enterprises...

Aluminum Forging: Crafting Durability and Efficiency Across Industries

Forging aluminum is a major component of modern manufacturing industry...