Chest Handle

A chest handle got its name for it is initially secured on chests. It is also used in cabinets, travel bags, drawers, tool boxes, doors, etc. It really does make handling much easier for us. Chest handles are meant to help us handle everything by pivoting 90 degrees through the baseplate.

Heavy-duty chest handles are made through Forging in which raw material is being shaped while heated, resulting in admirable strength, supreme toughness, highest capacity, and absolute reliability. Surface Preparation is the next step, this step confirms the surface’s readiness for polishing. Then Coating, its role is to give the component greater protection.

Zinc plated chest handle

Storage chest handle

Steel chest handle

Stainless steel chest handle

Stainless steel chest handle

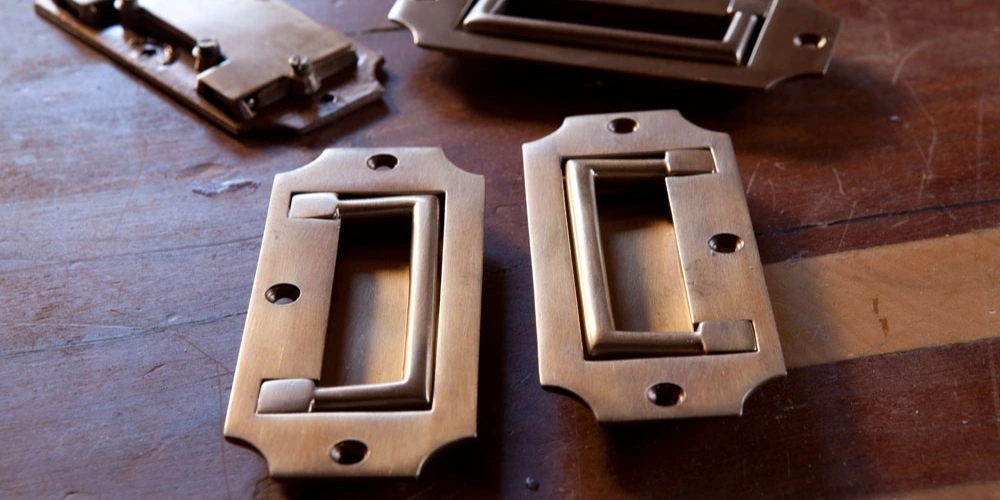

Brass plated chest handle

Brass chest handle

Heavy duty chest handle

Related Chest Handle

It is both well-built and unworrying to hold regardless of how heavy your suitcases are. As handles are needed in almost every piece of furniture, manufacturers thought of making them out of different raw materials, each of which has its own advantages.

Carbon Steel– greater comprehensive strength, exceptional hardness, adequate ductility.

Hollow Steel- extreme strength to weight ratio, lightweight, higher flexibility.

Stainless Steel– superb wear and abrasion resistance, can withstand fatigue and collision.

Aluminum– low-cost, lightweight, rust-resistant.

Brass– great malleability, functional and competent.

Copper- high thermal conductivity, corrosion resistance, recyclable.

Wrought Iron- tensile strength, malleable, corrosion resistance, strong.

Surface finishes are made to add more strength, and resistance, and preserve a certain component. When it comes to chest handles, they can be Plain, Zinc Plated, Brass Plated, Nickel Plated, Powder Coated, Matte Powder Coated, Electro Coated, Polished, and Passivate.

Decorating or coloring the part is a must with some, storage chest handles can be colored in gold, grey, silver, reddish-brown, and black.

When deciding on its overall height, chest handles can be customizable as you may consider the surface to where it will be attached. A height of 2-3/4” ~ 3-5/4” or longer would be great. The plate width can also be customizable, it can be 3⅖” ~ 4-22/25” or more as well. Holes may be as per your requirement, 3/4/5 or more or none.

There are two types of storage chest handle:

- Recessed- This type of handle is hidden, they are unnoticeable. They are embedded into the surface that presents an incredible finish.

- Non-Recessed- Unlike recessed, you can spot a non-recessed chest handle from the object’s side profile.

Chest Handle Specification | |||

| Width – Overall Dimensions | Length | Finish | Material |

| 1 7/16 in | 3 1/2 in | Brass | Steel |

| 2 15/16 in | 3 1/2 in | Brass | Steel |

| 2 7/16 in | 3 1/8 in | Zinc | Steel |

| 2 15/16 in | 3 1/2 in | Zinc | Steel |

Why choose HDC chest handle?

Choosing HDC as your heavy-duty chest handle supplier would be a great solution. We have numerous designs and sizes to select and to choose from. Our team is very pleased to accommodate you and develop your knowledge about chest handles especially when customizing them.

We are using chest handles on a daily basis, whether it be on bags, doors, trunks, cases, and many more. It helps us carry everything whenever we want. Customizing it with HDC will be a great way for you to achieve your preferred type and design specifically made for your appliance. We will always make things possible for you!

Frequently Asked Questions (FAQ) – Chest Handle

Welcome to our exhaustive FAQ guide on Chest Handles. Whether you’re delving into functionalities, materials, or customization, this guide provides insightful responses. Explore the intricate processes of crafting these vital furniture components, discover diverse chest handle types, and gain insights into installation techniques. We’re here to navigate the realm of chest handles, assisting you in informed decision-making aligned with your preferences.

What Is a Chest Handle?

A Chest Handle stands as an instrumental apparatus fashioned for the purpose of clenching and manipulating chests or akin storage furnishings. Functionally, it acts as a facilitative element, ensuring ease of utilization, while concurrently operating as an ornamental embellishment that enhances the comprehensive visual appeal of the chest. Conventionally affixed to the external facade of the chest, these handles exhibit a plethora of styles, compositions, and configurations, adeptly curated to accommodate both pragmatic requirements and stylistic inclinations.

What Are the Typical Components of a Chest Handle?

The standard constituents comprising a Chest Handle encompass integral elements designed for functionality and aesthetic appeal. These typically include a gripping mechanism, ensuring ease of manipulation, and an attachment structure for secure installation on the chest. The materials used in crafting these handles may vary, commonly incorporating metals or alloys for durability and visual appeal. Additionally, embellishments or ornamental features may be integrated, further contributing to the overall design and tactile experience of the Chest Handle.

What Materials Are Used in the Fabrication of Chest Handles?

In the crafting of chest handles, a melding of metallic and polymeric constituents is commonplace. Forged from stalwart alloys like steel, aluminum, or brass, these handles imbue robustness and tenacity. This alloyed fortitude equips them to endure the rigors imposed by the heft and strain entailed in hoisting and transporting chests.

Contrastingly, handles hewn from polymers, particularly the sturdier variants such as nylon or ABS (Acrylonitrile Butadiene Styrene), find prevalent use. Polymer handles, characterized by their feathery mass, exhibit resilience against corrosion, and proffer a heightened scope for innovative design. They stand as the favored choice in realms where the pivotal considerations are weight and economic outlay.

What Are the Various Types of Chest Handles?

In the realm of chest handles, distinctions arise based on installation—namely, embedded handles and surface-mounted handles.

- Embedded Handles: These, or recessed handles, seamlessly integrate into the chest’s structure, aligning flush for a sophisticated aesthetic. Ideal for minimalist designs, they avoid protrusion where undesirable.

- Surface-Mounted Handles: In contrast, surface-mounted handles directly affix to the chest’s exterior. They vary in styles like pull or bail handles, known for accessibility. Their adaptability suits diverse chest designs.

Which Metal Processing Techniques Are Employed in the Production of Chest Handles?

In the intricate world of crafting chest handles, two prevalent techniques take the limelight – namely, the nuanced artistry of metal bending in sculpting the graspable segment, and the precision-oriented approach of stamping in fashioning the foundational plate.

- Metal Bending: The method of metal bending reigns supreme, being the quintessential means for sculpting the ergonomic and functionally adept graspable facet of the chest handle. This process intricately involves the manipulation of metal sheets, bending them to conform precisely to the desired contour. The outcome is a tactile masterpiece, offering users a comfortable and secure hold.

- Stamping: Conversely, stamping asserts its significance in the creation of the foundational plate within the chest handle’s architecture. This intricate technique employs a die and press to meticulously cut or shape metal sheets, giving birth to the fundamental component that firmly secures the handle to the chest. Stamping ensures a level of precision and manufacturing efficiency that is unparalleled.

While metal bending and stamping stand as the most common methodologies, it’s crucial to acknowledge the vast array of other techniques, such as CNC machining, that contribute to the production of chest handles. These diverse approaches collectively enrich the landscape of handle manufacturing, offering versatility and innovation beyond the conventional.

What Finishes Are Suitable for Chest Handles?

- Polished: Lustrous termination for a traditional and refined aesthetic.

- Brushed: Surface texture boasting parallel delineations, exuding a contemporary and nuanced demeanor.

- Anodized: Electrochemical progression fostering immunity against corrosion, frequently applied to aluminum substrates.

- Nickel-Plated: Delicate stratum of nickel, bequeathing a luminous and corrosion-defying veneer.

- Galvanized: Application of a zinc envelopment upon steel, imparting superlative corrosion resistance, particularly suitable for al fresco applications.

- Chrome-Plated: Minute stratum of chromium, begetting an exceedingly reflective and contemporarily chic appearance.

- Powder Coating: Desiccated culmination procedure bestowing robustness and a myriad of customizable chromatic alternatives.

These culminations proffer an array of visual alternatives and pragmatic advantages, necessitating a decision contingent upon the preferred aesthetic, the context of the chest’s locale, and factors such as resistance to corrosion and enduring robustness.

How Are Chest Handles Typically Installed on Chests?

Chest handles are typically installed by marking and drilling pilot holes for screws or bolts at desired locations on the chest. The handles are then aligned and securely attached, with care taken not to overtighten. Stability is checked by gently tugging on the handles. If multiple handles are needed, the process is repeated. Optionally, a sealant or finish can be applied for protection and aesthetics. Specific instructions may vary based on handle type and chest material, and it’s advisable to consult manufacturer guidelines or seek professional assistance if needed.

How To Customize a Chest Handle?

To customize a chest handle from manufacturers, first, choose a reputable manufacturer with customizable options. Browse through available designs, materials, and finishes, specifying your preferences in size, material, and finish. Check pricing and lead time, and provide accurate measurements if necessary. Review and confirm your order, then patiently await delivery. Once the handles arrive, follow the manufacturer’s instructions for installation. Regularly communicate with the manufacturer if you have specific requirements or questions during the process.

Conclusion

Explore our rich FAQ guide on chest handles, unraveling the complexities from components to finishes. Whether seeking installation tips or contemplating customization, empower your choices with newfound insights. Reach out to HDC for further assistance. Trust us to enhance both functionality and aesthetics in your living spaces with our chest handles.

[toc]