- Home

- Custom Made Products

Custom Made Products

At HDC, we specialize in providing custom manufacturing solutions tailored to meet your exact specifications. Whether you need precision machining, advanced materials, or industry-specific parts, our expertise spans a wide range of processes and materials to deliver products that perform at the highest standards.

What Custom Products You Can Get From HDC?

Discover the wide range of custom-manufactured components HDC offers, tailored to meet the unique demands of various industries.

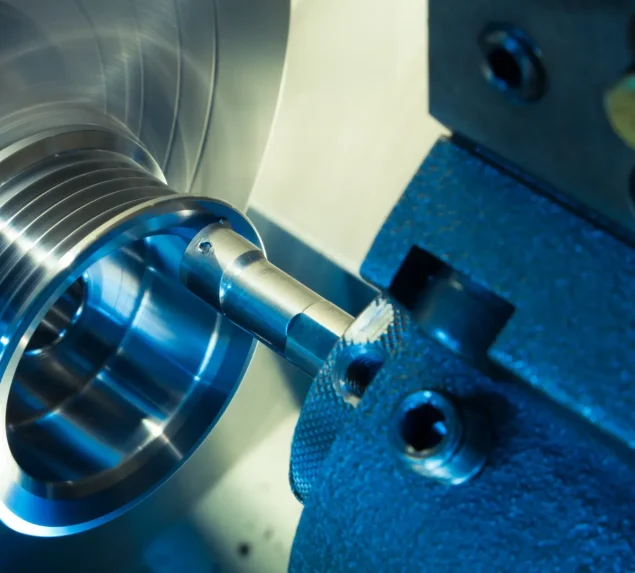

Precision CNC Machined Components

Custom machined parts with tight tolerances for industries like automotive, aerospace, and medical devices. Examples include gear housings, shafts, and surgical tools.

High-Strength Forged and Cast Metal Parts

Durable components designed for heavy-duty applications, such as structural supports, construction machinery parts, and industrial fasteners.

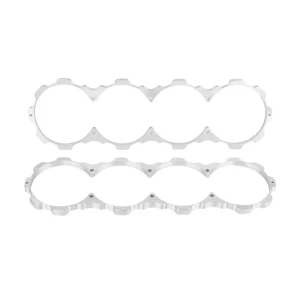

Laser-Cut and Stamped Sheet Metal Parts

High-precision sheet metal products for enclosures, brackets, decorative panels, and industrial equipment.

Specialized Fasteners and Connectors

Custom-engineered bolts, screws, clamps, and connectors for construction, transportation, and machinery applications.

Performance-Driven Racing Parts

High-performance components engineered for motorsports, including lightweight CNC-machined parts and durable forged wheels.

Complex 3D Printed Components

Rapidly manufactured parts with intricate geometries, ideal for prototypes and low-volume production in industries like healthcare, consumer electronics, and automotive.

Custom Products by Manufacturing Process

Tailored solutions based on advanced manufacturing techniques, ensuring precision and efficiency in every part.

CNC Milling High Precision Parts

CNC Turning Pipe Fitting

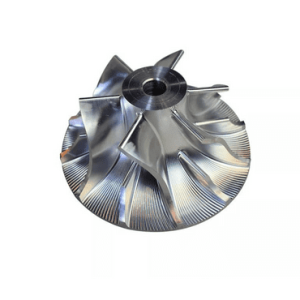

5 Axis CNC Machined Impeller

5 Axis CNC Milling Casing

CNC Swiss Screw Machine Parts

Precision CNC Milling Products

CNC Machining Prosthetic Parts

View Our CNC Machining Service

- 3-Axis, 4-Axis, and 5-Axis CNC Machining

- Tolerances as tight as ±0.001mm

- Max Part Size: 1000mm x 800mm x 500mm

- Min Part Size: 1mm x 1mm

Sheet Metal Bending Parts

Sheet Metal Bending & Stamping Parts

Sheet Metal Stamping Products

Brass Sheet Stamping Parts

Laser Cutting Sheet Metal Parts

Water Jet Cutting Products

Welding Sheet Metal Products

View Our Sheet Metal Fabrication Service

- Laser Cutting, CNC Punching, Bending, Welding

- Tolerances as tight as ±0.1mm

- Max Size: 2500mm x 1250mm

- Min Size: 10mm x 10mm

Forged Aluminum Motorcycle Wheel Hub

Forging Aluminum Suspension Arm

Aluminum Forging Connector

Aluminum Forging Motorcycle Parts

High-Strength Aluminum Forged Bracket

Forged Aluminum Structural Components

Aluminum Forging Bike Frame

View Our Sheet Metal Fabrication Service

- Technologies:Closed Die Forging

- Precision: Tolerances as tight as ±0.5mm

- Aluminum 6061, 7075

Nickel Alloy Investment Casting Connector

Investment Casting Hastelloy Part

Investment Casting Inconel Parts

Investment Casting Pipe Components

Investment Casting Monel Products

Investment Casting Valve Body

Investment Casting Casing

View Our Investment Casting Service

- Materials: Stainless Steel, High Temperature Nickel Alloy

- Precision: Tolerances as tight as ±0.5mm

- Max Size: 800mm x 500mm x 400mm

3D Printing Plastic Products

Plastic 3D Printing Connector

Metal 3D Printing Parts

View Our 3D Printing Service

- Materials: PLA, ABS, Nylon, Metal Alloys, Titanium, Stainless Steel

- Precision: Tolerances as tight as ±0.1mm

Custom Products by Material

Explore custom components crafted from a variety of high-quality materials, designed to meet your specific performance requirements.

View Our Steel Materials

- Common Materials: A36 Steel, 1045 Steel, 4140 Steel, 4340 Steel

- Key Benefits: High strength, Toughness, Excellent machinability

View Our Stainless Steel Materials

- Common Grades: 304, 316, 17-4 PH, 2205 Duplex

- Key Benefits: Corrosion resistance, Strength, Hygiene

View Our Aluminum Alloy Materials

- Common Grades: 6061, 7075, 2024, 5083

- Key Benefits: Lightweight, Corrosion resistance, High strength-to-weight ratio

Titanium Impeller

Custom-Made Titanium Alloy Component

5 Axis CNC Machined Titanium Parts

View Our Titanium Materials

- Common Grades: Ti-6Al-4V, Ti-5Al-2.5Sn, Ti Grade 2

- Key Benefits: Exceptional strength, Corrosion resistance, High temperature resistance

Casting Hastelloy Connection

Investment Casting Inconel Valve Body

Investment Casting Nickel Alloy Pipe Component

View Our Titanium Materials

- Common Grades: Inconel 625, Monel 400, Hastelloy C-276

- Key Benefits: Excellent heat resistance, Corrosion resistance, Strength at high temperatures

CNC Machining Brass Handle

Copper Connector

Stamping Copper Alloy Parts

View Our Titanium Materials

- Common Grades: C11000, C36000, C17200

- Key Benefits: Excellent electrical conductivity, High thermal conductivity, Corrosion resistance

Custom Products by Industry

Discover custom solutions tailored for diverse industries, offering specialized parts for unique applications and challenges.

View Our Custom Racing Parts

- Common Applications: Engine components, Suspension parts, Chassis

- Key Product Types: Lightweight alloys, High-strength fasteners, Precision machined parts

View Our Custon Products for Transportation Industry

- Common Applications:Connection systems, Brake components

5 Axis CNC Machining Aerospace Parts

Forged Aluminum Aerospace Parts

CNC Turning Aerospace Titanium Bolts

View Our Custom Aerospace Products

- Common Applications: Aircraft frames, Engine components, Fasteners

- Key Product Types: Lightweight alloys, High-precision parts, Corrosion-resistant components

CNC Machining Titanium Bone Bolts

CNC Machining Prosthesis Components

CNC Machining Dental Implant

View Our Custom Medical Products

- Common Applications: Surgical instruments, Implants, Medical devices

- Key Product Types: Stainless steel parts, Titanium components, Biocompatible materials

Steel U Bolt for Pipe Line

Stamping Parts for Construction Industry

Aluminum Forging Construction Tool

View Custom Products for Construction Industry

- Common Applications: Structural supports, Reinforced beams, Fasteners

- Key Product Types: Steel components, Heavy-duty parts, Custom connectors

CNC Machining Gears for Machinery Industry

Precision CNC Machining Transmission Gear

Industry Machine Roller Chain Sprocket

View Custom Products for Machinery Industry

- Common Applications: Gearboxes, Bearings, Hydraulic components

- Key Product Types: Castings, Precision-machined parts, High-strength fasteners

Our Customization Process

At HDC, we offer a seamless customization process to ensure your project is completed to your exact specifications, on time and within budget. Here’s how we work with you:

1. Contact Us and Submit Your Design

Provide sketches, drawings, or ideas to kick-start the customization process.

2. Material and Process Selection

Our experts help you choose the ideal material and manufacturing method for your needs.

3. Quote and Approval

Receive a detailed quote and approve the design specifications before production.

4. Prototyping and Testing

A prototype is created and tested to ensure it meets all requirements.

5. Full-Scale Production

Your custom product is manufactured using advanced techniques for precision and quality.

6. Quality Inspection and Delivery

Every product undergoes rigorous quality checks before being securely packaged and shipped.

FAQ

Find answers to common queries about our custom parts and services.

To begin the customization process, you need to provide detailed drawings, sketches, or 3D models. Additional specifications such as material type, dimensions, surface finish, and quantity are also helpful for accurate quotes and production.

The MOQ varies depending on the manufacturing process. For example, CNC machining may start at 100 pieces, while forging and casting may require several hundred or more. Contact us for details on your specific needs.

Timelines depend on the complexity and quantity of your order. Prototyping typically takes 1–3 weeks, while full-scale production can range from 3–8 weeks. We provide precise timelines after reviewing your project.

We work with a wide range of materials, including aluminum, stainless steel, titanium, copper, nickel alloys, and plastics. Each material is selected based on your specific application and performance requirements.

Yes, we offer prototyping services. Prototypes allow you to evaluate the design and functionality before committing to full production. Costs and lead times depend on the complexity of the prototype.

Our precision levels vary by process. CNC machining achieves tolerances as tight as ±0.001mm, while casting and forging typically maintain tolerances within ±0.5mm. Specific tolerances can be customized based on your requirements.

Yes, we provide various finishing options, including powder coating, anodizing, polishing, heat treatment, and more. Finishing services are tailored to enhance both appearance and durability.

Our strict quality control process includes material inspection, precision testing, and final product evaluation. We use advanced equipment like CNC machines, CMMs, and hardness testers to ensure every product meets specifications.

Yes, we provide comprehensive logistics support, including FOB shipping, customs documentation, and export expertise. This ensures smooth delivery to clients worldwide.

We accept multiple payment methods, including wire transfers, PayPal, and credit cards. Standard terms include a deposit before production, with the balance due before shipment. Specific terms can be discussed based on the order size.

Get an Instant Quote!

Ready to start your next project with HDC? We’re here to help with all your custom metal fabrication needs. Get in touch today!

Contact With Us

for any inquiry