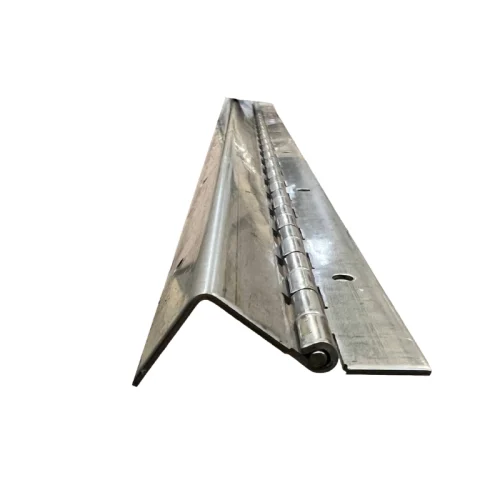

Custom Piano Hinge Supplier

With the powerful sheet metal fabrication capabilities, HDC has become a professional piano hinge manufacturer for over 10 years. We provide our customers with comprehensive customization options to build piano hinges that perfectly align with their specific applications.

From marine applications to industrial heavy-duty gates, HDC piano hinges always provide a stable and reliable connection solution for various scenarios.

Highly Customizable

Fast Turnaround

Mass Production

Competitive Price

Piano Hinge Materials

HDC offers custom piano hinge service with multiple material options. Thickness ranges from 0.5mm to 10mm, suitable for all kinds of applications.

Available Carbon Steel Grades:

Carbon steel is preferred for manufacturing piano hinges because of its low material cost, excellent strength, and versatile grades. But the corrosion resistance of carbon steel is weaker than aluminum and stainless steel, so carbon steel piano hinges need additional surface treatment, like zinc plating, to enhance their corrosion resistance.

- 1018 Steel: 1018 steel is a low-carbon steel with 0.18% C content. It has excellent ductility, is easy to cold form (such as stamping, bending).

- 1045 Steel: 1045 steel has 0.20% Carbon content, slightly higher than 1018, and is a medium carbon steel. Suitable for heavy-load piano hinges.

Available Stainless Steel Grades:

Stainless steel is an ideal choice for piano hinges, the common grades include 304 and 316. They are valuable for their excellent corrosion resistance and shiny silver appearance without additional surface finishing.

- Stainless Steel 304: As a general purpose austenitic stainless steel, SS 304 has excellent corrosion resistance, suitable for most indoor use.

- Stainless Steel 316: The addition of molybdenum gives 316 stainless steel excellent resistance to chloride ion corrosion, making it a wise choice for marine and chemical applications.

- Stainless Steel 410: As a martensitic stainless steel, 410 can be heat treated to achieve superior strength and wear resistance, suitable for heavy duty industry applications. But its corrosion resistance is relatively lower than 304/316, and may need additional surface treatment in a moist environment.

Available Aluminum Grades:

Aluminum is used in the manufacture of piano hinges for its balance between strength, corrosion resistance, and light weight. HDC fabricates the piano hinge with different grades of aluminum to meet various requirements.

- Aluminum 6061-T6: 6061 is one of the most common aluminum alloys in the market. It is about 65% lighter than steel, and can be easily machined with bending and stamping.

- Aluminum 5052-H32: 5052 combines strength and formability, though the strength is slightly lower than 6061, but its machinability is better, making it suitable for the piano hinge with a thin leaf.

- Aluminum 7075-T6: As an aerospace grade metal, 7075 has the highest strength among aluminum alloys, making it the best choice for piano hinges requiring strength and lightweight.

Available Copper Alloy Grades:

There are many types of copper alloys, and their properties are very different. HDC can customize copper alloy piano hinges for decorative or industrial use.

- C26000: C26000 contains 70% copper and 30% zinc, which makes it have excellent cold formability, highly suitable for stamping and bending. With its golden yellow luster, copper hinge is mostly used in decorative applications, such as pianos and classical furniture.

- C51000: C51000(Cu-Sn-P) is also known as phosphor bronze, which has excellent wear resistance and fatigue resistance, and at the same time, corrosion resistance is better than ordinary brass, which is very suitable for manufacturing industrial hinges with frequent opening and closing and high loads.

Piano Hinge Finishes

Surface treatment can effectively extend the service life of a hinge. HDC mainly provides the following surface treatments for piano hinges made of different materials.

Types of Piano Hinge

Piano hinge is a versatile product that can be customized with various materials, finishes, and dimensions. Below are the common types HDC can fabricate.

How Can HDC Customize Piano Hinge

1. Customizable Dimensions

At HDC, you can customize a piano hinge with a wide range of dimensional options, including thickness, width, length, pin diameter, and hole pitch. Below are the specific customizable size details:

- Thickness: 0.5–10 mm

- Width: 10–500 mm

- Length: 10–6000 mm

- Pin Diameter: 1–20 mm

- Hole Pitch: 5–200 mm

2. Customizable Materials and Finisehs

When customizing piano hinges, the application scenario and load-bearing capacity should be considered first, and then the appropriate materials and finishes should be selected based on these factors. HDC mainly provides 4 types of materials and 7 types of finishes to satisfy different requirements:

- Materials: carbon steel, stainless steel, aluminum, copper.

- Finishes: blackening, powder coating, chrome/zinc/nickel plating, painting, and brushing.

3. Customizable Features

HDC can tailor a continuous hinge with any additional features according to your drawings or samples. Below are some common features we provide:

- Offset Piano Hinge

- Stop Piano Hinge

- Piano Hinge with Spring

- Interleaf Continuous Hinge

- Piano Hinge with Removable Pin

Why Choose HDC

Why Choose HDC

HDC is trusted by hundreds of customers for providing reliable continuous hinges. Our products are used in a wide range of fields, including automotive, construction, furniture manufacturing, electrical appliances, and the marine industry.

- Source Factory: We are a source factory equipped with a full set of production equipment.

- One Stop Service: One-stop service from design, development, drafting, processing, surface treatment to packaging.

- Mass Production: We have the capability for rapid scaling of production, enabling us to handle large-volume orders and ensure on-time delivery.

- Competitive Price: As a factory, we are able to offer more competitive prices.

One Stop Piano Hinge Customization Service

The piano hinge can be simply thought of as an elongated hinge. It was originally used to attach the lid of a piano, providing a seamless, smooth and quiet connection, which is also the origin of the name "piano hinge", which is also often referred to as "continuous hinge".

Piano hinges can be customized to the length of the mounting surface, typically covering the full length of the connecting edge to distribute the load for optimal support evenly. Still, they can also be cut or spliced to the desired length as required.

Yes, we provide a discount for a large order.

Usually, the MOQ is 500 pieces, but it may vary according to the specific product. Please contact us for specific MOQ, provide product information, and discuss.

Yes, all customers are welcomed to visit our factory.

It depends. For standard dimensions, like width, pin diameter, etc., we have ready-made molds. But for the specifically customized models, molds are needed. HDC has the ability to design and manufacture molds according to drawings or samples.

Yes, usually you need to pay for the mold. If the order quantity meets the requirements, the mold cost can be refunded at the subsequent large-scale production settlement.

We can discuss the details.