Hersteller von hochfesten Schmiederohrverbindungsstücken

Komplett individualisierbarer Lieferant von Schmiederohrverbindungsstücken in China. Industrielle Komplettlösung aus einer Hand – von der Formenherstellung über die Serienfertigung bis hin zur Endbearbeitung.

Arten von geschmiedeten Rohrverbindungsstücken

HDC fertigt Rohrverbindungsstücke aller Art, um Ihre spezifischen Projektanforderungen zu erfüllen. Hier sind die gängigen Typen:

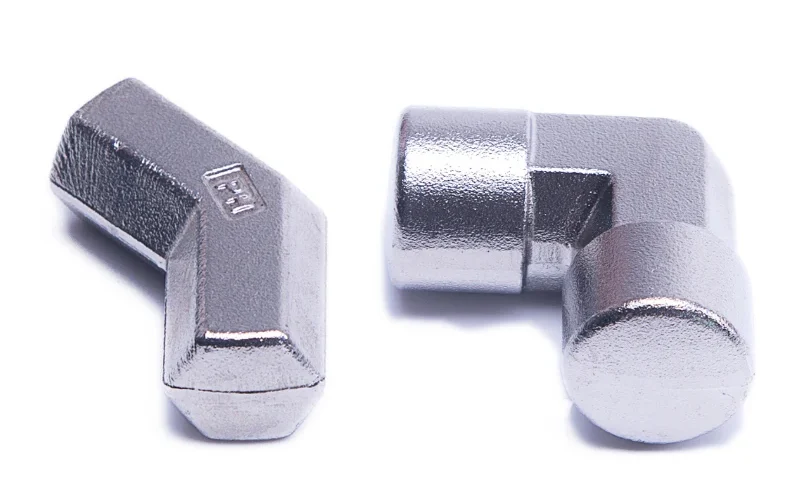

Geschmiedeter Winkel

Ein Rohrbogen dient dazu, zwei Rohre in einem gewünschten Winkel zu verbinden. Standardmäßig hat er einen Winkel von 90° oder 45°. Bei HDC können Sie aber auch jeden beliebigen Winkel für Ihr Projekt individuell anpassen lassen.

Geschmiedetes T-Shirt

Ein geschmiedetes T-Stück ermöglicht den Anschluss von drei Rohren im 90°-Winkel zur Verteilung oder Sammlung von Flüssigkeiten. Neben dem Standard-90°-T-Stück fertigt HDC auch 45°- oder 60°-T-Stücke nach Ihren Vorgaben.

Geschmiedetes Kreuz

Ein geschmiedetes Kreuzstück dient zum Verbinden von Rohren aus vier Richtungen. Es wird hauptsächlich in Mehrrichtungs-Durchflusssystemen oder als Verbindungsstück für Rohrrahmen eingesetzt. HDC bietet sowohl flache als auch Eck-Vierwege-Schmiedefittings an.

Geschmiedete Verbindung und Kupplung

Eine Verschraubung und eine Kupplung dienen beide dazu, zwei Rohre zu verbinden. Der Hauptunterschied besteht darin, dass eine Verschraubung zur Wartung leicht demontiert werden kann, während eine Kupplung eine dauerhaftere Verbindung herstellt.

Geschmiedete Endkappe

Wie der Name schon sagt, dient eine Endkappe dazu, das Ende einer Rohrleitung sicher und dicht zu verschließen. Bei HDC sind sowohl Gewinde-, Schweiß- als auch Sechskantkappen erhältlich.

Geschmiedeter Reduzierer

Benötigen Sie ein Verbindungsstück für Rohre mit unterschiedlichen Durchmessern? Dann ist ein geschmiedetes Reduzierstück die beste Wahl. Ob 3-, 4- oder 5-Wege-Reduzierstück – HDC fertigt es zuverlässig für Sie.

Schmiedematerialien für Rohrverbindungsstücke

Bei HDC können wir Rohrverbindungsstücke aus über 30 Metallsorten schmieden.

Stahl

Stahl ist das am häufigsten verwendete Metall beim Schmieden, zum Beispiel Q355, Q235, 20Cr, und 40Cr. Es bietet ein ausgewogenes Verhältnis von Festigkeit, Rostbeständigkeit und Kosten. Die aus Stahl gefertigten Rohrverbindungsstücke werden hauptsächlich in Rohrleitungen eingesetzt, die nicht korrosive Flüssigkeiten wie Wasser, Luft und Dampf transportieren.

Rostfreier Stahl

Edelstahl verbessert seine Korrosionsbeständigkeit hauptsächlich durch die Beimischung von Chrom und Nickel. 304 und 316 Aufgrund ihrer guten Umformbarkeit werden sie am häufigsten für die Herstellung von Schmiederohrfittings verwendet. Obwohl diese Fittings für die meisten Medien geeignet sind, muss der dreifach höhere Preis im Vergleich zu Stahl berücksichtigt werden.

Aluminiumlegierung

Die Kombination aus bemerkenswerter Formbarkeit, ausgezeichnetem Festigkeits-Gewichts-Verhältnis und natürlicher Korrosionsbeständigkeit ohne jegliche Oberflächenbehandlung macht die Aluminiumlegierung (6061, 6075Aluminium hat sich zu einem idealen Metall für die Schmiedetechnik entwickelt. Geschmiedete Rohrverbindungsstücke aus Aluminium werden hauptsächlich in Niederdruck- oder Leichtbau-Rohrleitungssystemen eingesetzt.

Titan

Dank seines hervorragenden Festigkeits-Gewichts-Verhältnisses und seiner ausgezeichneten Korrosionsbeständigkeit hat sich Titan zu einem bevorzugten Werkstoff für anspruchsvolle Anwendungen entwickelt. Bei HDC schmieden wir Rohrverbindungsstücke aus Titan. Note 2 und Klasse 5 Titan für Ihre High-End- oder Extremanwendungen.

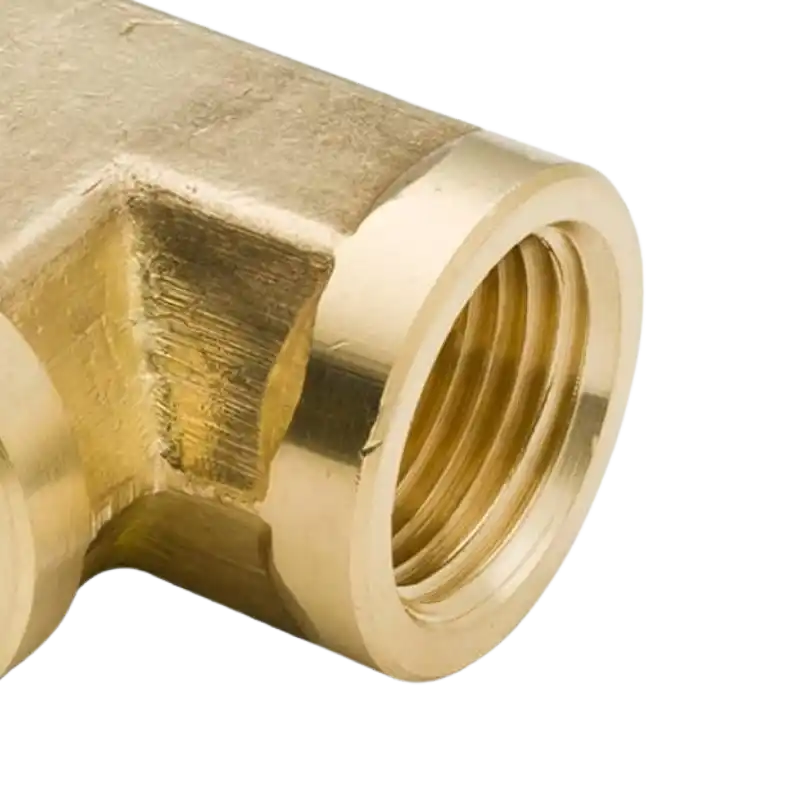

Messing

Messing ist eine Kupferlegierung, die hauptsächlich aus Zink besteht. Aufgrund seiner natürlichen Rostbeständigkeit, guten Bearbeitbarkeit und seines goldglänzenden Aussehens wird es bevorzugt in Rohrleitungssystemen eingesetzt. Messingsorten wie C37700 und C37800 sind die gängigen Sorten, die HDC für die Herstellung von Schmiederohrfittings verwendet.

Nickellegierung

Rohrverbindungsstücke aus Nickellegierungen sind beständig gegen extrem raue Umgebungsbedingungen wie hohe Temperaturen (>600°C), stark korrosive Bedingungen und hohen Druck. Inconel 625, Monel 400, und Incoloy 825 sind die am häufigsten verwendeten Nickellegierungen für die Herstellung von Schmiederohrfittings.

Oberflächenbearbeitung und Nachbearbeitung für Rohrverbindungen

HDC bietet eine breite Palette an Oberflächenveredelungen für geschmiedete Rohrverbindungsstücke an.

| Oberflächenbehandlung | |

|---|---|

| Beizen und Passivieren | Entfernt Zunder und Oxidschichten, um den metallischen Glanz wiederherzustellen. |

| Sandstrahlen | Reinigt und rauet die Oberfläche auf, um eine bessere Haftung der Beschichtung zu gewährleisten. |

| Kugelstrahlen | Erzeugt eine gleichmäßige, matte Oberfläche und erhöht die Dauerfestigkeit. |

| Beschichtung | |

| Galvanik | Fügt eine schützende oder dekorative Metallbeschichtung hinzu, um Korrosionsbeständigkeit und Aussehen zu verbessern. Wir bieten alle gängigen Beschichtungen an, darunter: Verzinken, Vernickeln und Verchromen. |

| Eloxieren | Bildet eine widerstandsfähige Oxidschicht für Korrosions- und Verschleißbeständigkeit. Hauptsächlich für Titan und Aluminium. Anodisierung Typ II und Typ III ist verfügbar. |

| Schwarzoxid (Schwärzen) | Verbessert die Korrosionsbeständigkeit und sorgt für ein dunkles Aussehen. |

| CNC-Bearbeitung | |

|---|---|

| Langweilig | Vergrößert oder bearbeitet Innenbohrungen auf präzise Abmessungen. |

| Gewindeschneiden | Erzeugt Innen- oder Außengewinde nach Standardgrößen. |

| Konfrontiert | Glättet und begradigt die Endfläche für eine präzise Passform. |

| Bohren | Erzeugt saubere Bohrungen für Flüssigkeits- oder Schraubverbindungen. |

| Drehen / Fräsen | Erreicht die endgültigen Abmessungen, die Oberflächenbeschaffenheit und die Toleranzen. |

Größen- und Toleranzspezifikationen

Informieren Sie sich über unsere Fertigungsmöglichkeiten für geschmiedete Rohrverbindungsstücke, einschließlich Gewicht, Größe und Toleranz.

| Schmiedegewichtsbereich | 0,03 kg – 30 kg | Geeignet für kleine bis mittelgroße geschmiedete Rohrverbindungsstücke. |

| Schmiedepressenkapazität | 160T – 4000T | Deckt ein breites Spektrum an Anforderungen im Bereich der Metallumformung ab. |

| Außendurchmesser (OD) | Bis zu 300 mm | Sondergrößen auf Anfrage erhältlich. |

| Wandstärke | 3 mm – 50 mm | Hängt von Design und Material ab. |

| Länge / Gesamtgröße | Bis zu 400 mm | Kann je nach Teilegeometrie variieren. |

| Maßtoleranz (geschmiedet) | ±0,5 mm – ±1,0 mm | Standardtoleranzen im Schmiedezustand vor der Bearbeitung. |

| Maßtoleranz (nach der Bearbeitung) | ±0,01 mm – ±0,05 mm | Erreicht durch CNC-Präzisionsbearbeitung. |

| Gewindegenauigkeit | Bis Klasse 3A/3B (ANSI) oder ISO 6H | Innen- und Außengewinde nach internationalen Standards. |

| Oberflächenrauheit (Ra) | Ra 0,8–3,2 μm | Abhängig vom Bearbeitungs- und Veredelungsverfahren. |

Vorteile des Schmiedens von Rohrverbindungsstücken

Warum benötigt man ein geschmiedetes Rohrformstück anstelle eines Guss- und CNC-Bearbeitungsteils? Hier ist die Antwort.

Im Vergleich zu gegossenen und CNC-bearbeiteten Rohrverbindungsstücken bieten geschmiedete Rohrverbindungsstücke einige Vorteile, die Sie berücksichtigen sollten, insbesondere wenn Ihre Projekte eine stabile und leistungsstarke Verbindungslösung erfordern.

- Hohe FestigkeitDurch das Schmieden wird die Kornstruktur des Metalls verfeinert und der Faserverlauf entlang der Kontur des Formteils ausgerichtet, wodurch eine durchgehende Faserstruktur entsteht, die die Zugfestigkeit, die Schlagfestigkeit und die Dauerfestigkeit erhöht.

- Wenige interne MängelDurch Schmieden lassen sich innere Defekte wie Porosität oder Lunker beseitigen, die beim Guss oder beim CNC-Bearbeiten des Rohlings auftreten können.

- Kosteneinsparung bei der MassenproduktionGießen erfordert lange Produktionsläufe, während CNC-Bearbeitung bei asymmetrischen Rohrverbindungsstücken zu viel Material verschwendet. Schmieden hingegen ermöglicht die Herstellung von Rohlingen in nahezu endgültiger Form innerhalb von Sekunden, die nur minimale CNC-Nachbearbeitung benötigen, um die Endprodukte zu erhalten. Dies kann die Kosten in der Massenproduktion hochwertiger Rohrverbindungsstücke erheblich senken.

- MaterialvielfaltDurch Schmieden lassen sich die meisten auf dem Markt erhältlichen Werkstoffe verarbeiten, wie zum Beispiel Edelstahl, Aluminiumlegierungen, Titan und Kupferlegierungen usw.

- Lange Lebensdauer und höhere SicherheitDank ihrer hohen Festigkeit und dichten Kornstruktur sind geschmiedete Rohrverbindungsstücke unter langfristiger Belastung durch hohen Druck, hohe Temperaturen und zyklische Belastung zuverlässiger.

Wie HDC Ihre Rohrverbindungsstücke schmiedet

Bei HDC verwenden wir das Gesenkschmieden zur Herstellung von Rohrverbindungsstücken für Ihr Projekt.

Als professioneller Hersteller von Schmiedeteilen befolgt HDC ein Standardverfahren zur kundenspezifischen Anfertigung von Schmiederohrfittings. Hier ist der gesamte Prozess von der Auftragserteilung bis zum endgültigen Versand:

- DFM-Überprüfung & Formenbau: Nach Eingang Ihrer Bestellung prüfen wir zunächst die Herstellbarkeit Ihres Designs und beraten Sie aus fachlicher Sicht. Anschließend fertigen wir die Form für das Gesenkschmieden mit unseren hauseigenen 4- und 5-Achs-CNC-Maschinen.

- Materialvorbereitung und SchmiedenWir prüfen jede Materialcharge auf Zusammensetzung und physikalische Eigenschaften. Anschließend schneiden wir die Rohmaterialien auf die passende Größe zu, erhitzen sie auf die gewünschte Temperatur und schmieden sie schließlich mit unserer automatisierten Schmiedeanlage zum Rohling.

- WärmebehandlungWir wärmebehandeln den Rohling, um seine Festigkeit, Härte und Verschleißfestigkeit durch Auslagern, Anlassen und Lösungsglühen usw. zu verbessern.

- CNC-BearbeitungNach der Wärmebehandlung durchläuft der Rohling eine Reihe von Bearbeitungsprozessen, um die gewünschte Form und Toleranz zu erreichen. Dazu gehören unter anderem das Plandrehen, drehen, Bohren, Gewindeschneiden, Anfasen usw.

- OberflächenbehandlungIn diesem Schritt werden wir die Rohrverbindungsstücke mit den von Ihnen gewünschten Oberflächenbehandlungen versehen.

- Inspektion & VerpackungAbschließend prüfen wir das Endprodukt mittels Koordinatenmessmaschine (KMM) und Eindringprüfung (FPI), um die Qualität sicherzustellen. Anschließend werden die Armaturen sorgfältig verpackt und per Luft- oder Seefracht direkt zu Ihnen geliefert.

Qualitätskontrolle

Die Qualitätskontrolle von HDC erstreckt sich über den gesamten Herstellungsprozess, vom Rohmaterial bis zum Endprodukt.

- Spektrometer: Vor dem Schmieden die chemische Zusammensetzung des Metalls prüfen.

- Härte- und ZugfestigkeitsprüfgerätStellen Sie sicher, dass die physikalischen Eigenschaften Ihren Anforderungen entsprechen.

- Fluoreszierende Eindringprüfungslinie(FPI): Nach dem Schmieden innere Defekte wie Risse und Porosität erkennen.

- Koordinatenmessgerät (CMM): Prüfen Sie die komplexen Geometrien und wichtigen Abmessungen wie Montageflächen, Dichtflächen, Gewindebohrungen und Passbohrungen eines Rohrformstücks. Stellen Sie sicher, dass sich das Produkt nahtlos in Ihr Projekt integrieren lässt.

Benötigen Sie maßgefertigte Schmiederohrfittings?

Sie benötigen individuell angefertigte Schmiederohrfittings, haben aber keine Erfahrung in der Fertigung? Kontaktieren Sie uns für technische Beratung oder ein individuelles Angebot.

FAQ

Welches Schmiedeverfahren verwendet HDC zur Herstellung von Rohrverbindungsstücken?

Wir fertigen Rohrverbindungsstücke im Gesenkschmiedeverfahren. Mit unserer Schmiedepresse und Schraubenpresse bietet HDC Ihnen Warm- und Kaltschmieden für die Herstellung von Rohrverbindungsstücken an.

Was ist ein geschmiedetes Rohrverbindungsstück?

Ein geschmiedetes Rohrformstück wird hergestellt, indem ein massiver Metallblock unter hohem Druck geformt wird, typischerweise durch Gesenkschmieden.

Zuerst wird der Rohling auf eine bestimmte Temperatur erhitzt und dann zwischen Ober- und Untergesenk einer Schmiedepresse eingesetzt. Anschließend presst die Presse die beiden Hälften zusammen; der Rohling in der Mitte wird dabei verformt, um den Gesenkhohlraum auszufüllen und einen Rohling in der Form des Endprodukts zu erhalten.

Anschließend wird der Rohling mittels CNC-Bearbeitung auf die gewünschten Abmessungen und Toleranzen hin bearbeitet. Dies umfasst Stirnfräsen, Gewindeschneiden, Bohren, Gewindebohren und Drehen.

Was ist die ASME-Norm für Schmiedefittings?

Die meisten Schmiedefittings folgen ASME B16.11, Die Norm legt die Regeln für Schweißmuffen- und Gewindeverbindungen fest. Sie definiert Größe, Nenndruck und Toleranz und gewährleistet so, dass jede Verbindung in industriellen Systemen sicher passt und funktioniert.

Worin besteht der Unterschied zwischen gegossenen und geschmiedeten Rohrverbindungsstücken?

Gussfittings werden hergestellt, indem flüssiges Metall in eine Form gegossen wird, um das Endprodukt direkt zu formen. Dadurch ist nur eine minimale Nachbearbeitung erforderlich, und es können Fittings hergestellt werden, die mit anderen Verfahren schwer zu realisieren sind, wie z. B. dünnwandige und innenverzahnte Konstruktionen.

Die geschmiedeten Fittings werden durch das Komprimieren von erhitztem Vollmetall geformt. Dadurch weisen sie eine höhere Festigkeit auf und sind auch bei hohen Belastungen langlebiger.

Worin besteht der Unterschied zwischen geschmiedeten und gewalzten Rohrverbindungsstücken?

Geschmiedete Fittings werden durch Walzen oder Extrudieren geformt. Geschmiedete Fittings entstehen durch Druck in einer geschlossenen Matrize. Geschmiedete Fittings sind im Allgemeinen fester und werden in Anwendungen mit hoher Beanspruchung oder hohem Druck eingesetzt.

Welche drei Arten von Rohrverbindungsstücken gibt es?

Die Haupttypen sind Stumpfschweißung, Muffenschweißen, und Gewindefittings. Beim Stumpfschweißen werden Rohre durch Verschweißen der Enden verbunden, beim Muffenschweißen wird eine Muffenverbindung verwendet, und Gewindefittings werden zur einfachen Montage zusammengeschraubt.

Was ist ein Beispiel für ein Schmiedeteil?

Gängige Beispiele für geschmiedete Fittings sind: Winkelstücke, T-Stücke, Kupplungen, Verschraubungen, Reduzierstücke und Kappen. Diese Bauteile dienen zum Verbinden, Verlängern oder Umlenken von Rohrleitungssystemen. HDC fertigt alle diese Bauteile im Gesenkschmiedeverfahren mit anschließender präziser CNC-Bearbeitung nach Kundenzeichnungen.