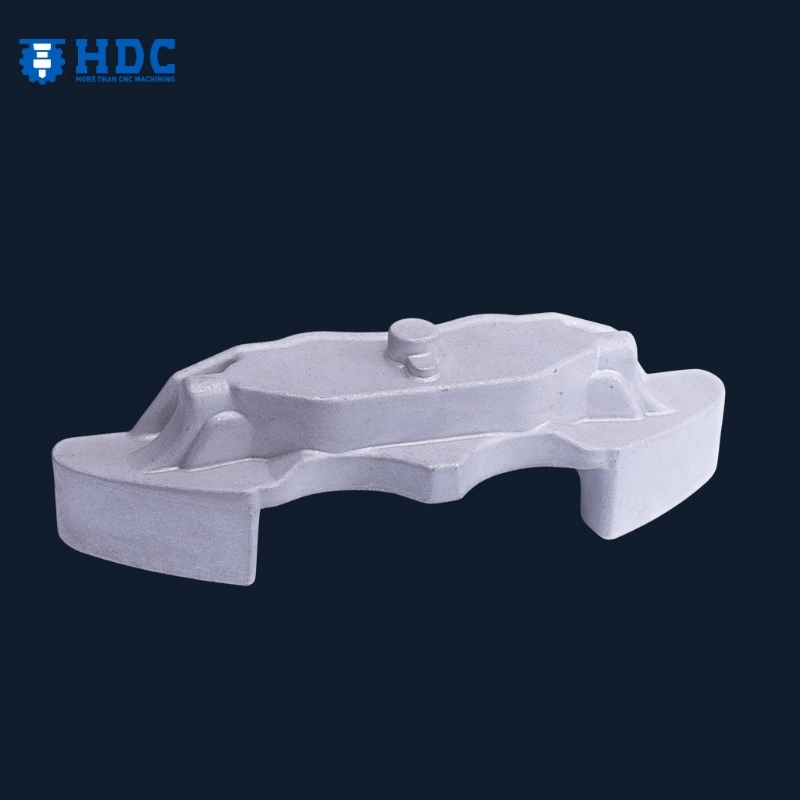

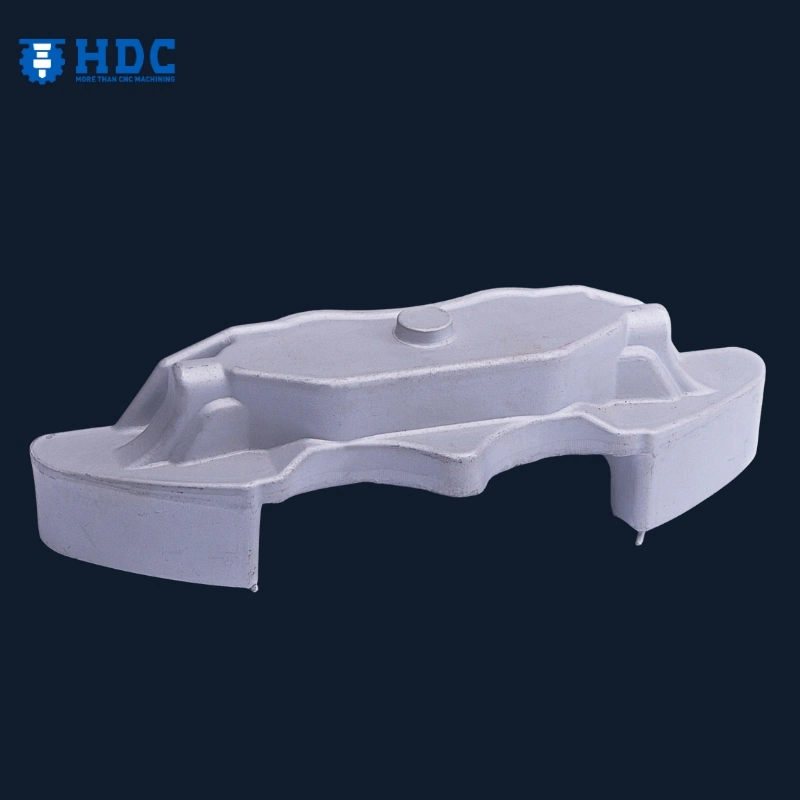

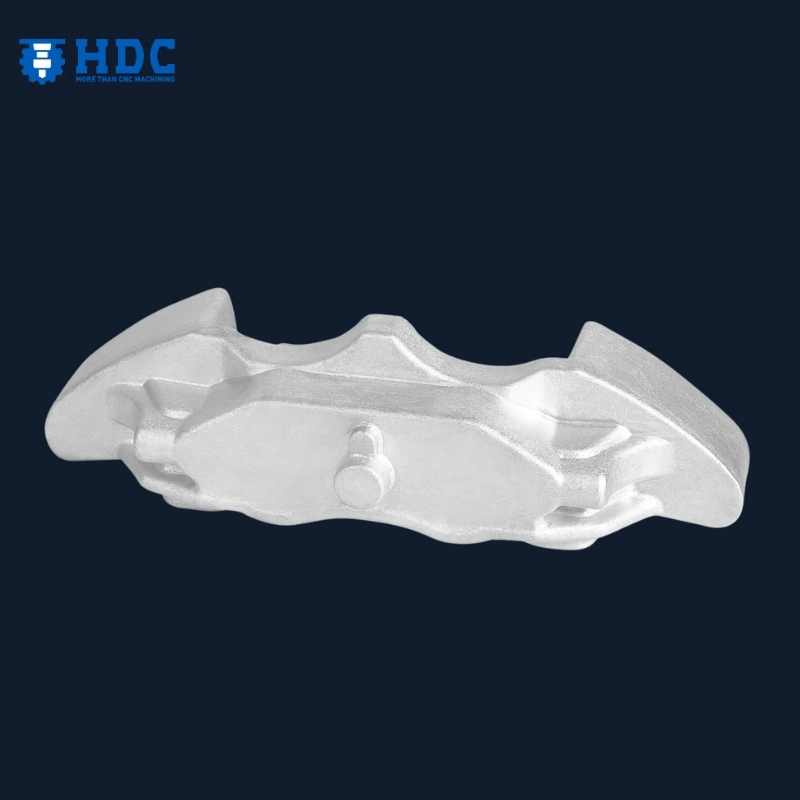

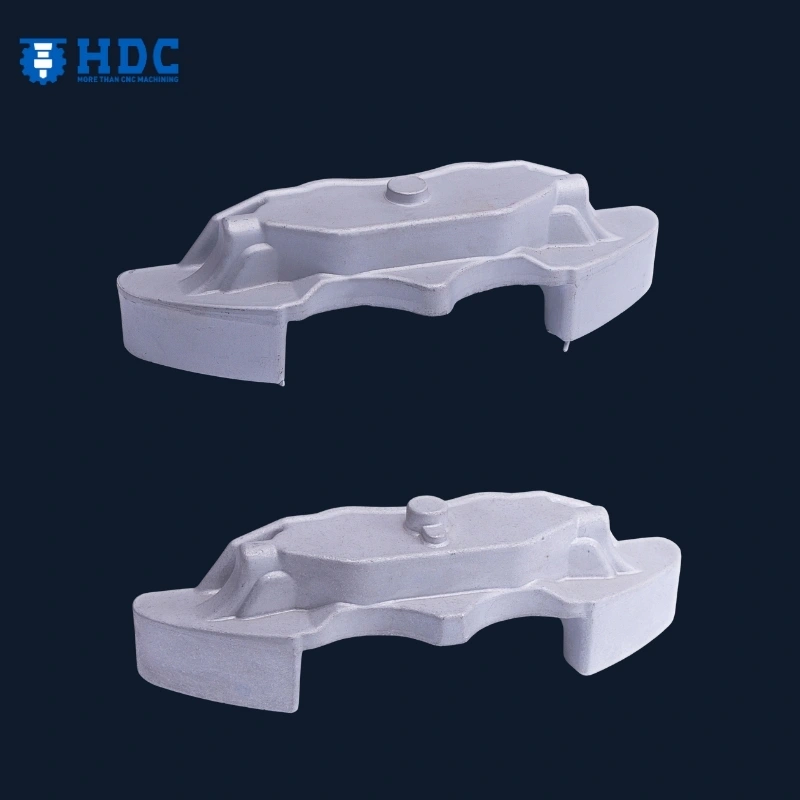

Präzisionsgefertigter, geschmiedeter Bremssattel aus Aluminium/Stahl-Legierung für Scheibenbremsen

Details zu kundenspezifischen Produkten

| Modell Nr. | HDCFCC001 |

| Stil | Geschmiedeter Bremssattel |

| Material | Aluminium, Aluminiumlegierung, Stahl, Stahllegierung |

| Finish-Typ | Unbehandelt, poliert, eloxiert, elektrophoretisch beschichtet, pulverbeschichtet, galvanisiert, verchromt, schwarz oxidiert |

| Verfügbare Größe | / |

| Mindestbestellmenge | 100 Stk. |

| Benutzerdefiniertes Logo | Verfügbar |

| Herkunft | China |

| Verpackung & Lieferung | |

| Versandoption | Kurier-, Luft-, See-, Bahnexpress, EXW, FOB, CIF, DDU, DDP |

| Liefertermin | 25-30 Tage |

| Transportpaket | Kundenspezifisch, Karton, Palette |

Command every braking event with absolute confidence and repeatable power using this precision custom-forged brake caliper. Precision-engineered for vehicles demanding race-bred clamping force and thermal resilience, this caliper transforms hydraulic pressure into precisely modulated stopping power—delivered with the structural integrity only closed-die forging can provide.

Dual-Material High-Strength Selection: Available in lightweight forged aluminum for significant unsprung mass reduction, or high-strength steel alloy for maximum thermal rigidity—each hot-forged to optimize grain flow along critical load paths for exceptional fatigue resistance.

Superior Stiffness-to-Weight Ratio: Precision forging densifies material structure, delivering billet-defying rigidity at a fraction of the mass—minimizing caliper body flex under extreme hydraulic pressure for consistent pad contact and linear lever feel.

Thermal Performance Optimization: Forged architecture inherently manages heat soak, while optional bridge cooling ducts and piston bore treatments enhance fluid temperature stability during sustained heavy braking.

Vollständig anpassbare Konfiguration: Manufactured to customer-specific piston counts, bore diameters, mounting lug spacing, and vehicle platform requirements—accommodating radial or axial mounting, fixed or floating designs, and bespoke aesthetic execution.

CNC-Machined Precision Interfaces: All pad retention surfaces, piston bores, and mounting faces are finish-machined to micrometer tolerances, ensuring perfect rotor alignment, pad retraction, and seal integrity.

Track-Ready, Street-Civilized: Delivers the bite and modulation of competition braking hardware without sacrificing daily-driver pedal compliance or noise, vibration, and harshness characteristics.

Anwendungen:

Hochleistungsstraße & Rennstrecke: Essential for sport sedans, coupes, and supercars requiring fade-free braking during aggressive canyon driving or lapped sessions.

Heavy-Duty & Towing Applications: Steel alloy variant ideal for light trucks, SUVs, and commercial vehicles demanding sustained braking capacity under load.

Custom & Restomod Builds: Suitable for vintage chassis retrofits, restomod projects, and one-off specials requiring period-correct aesthetics with modern clamping performance.

More than a hydraulic clamp, this forged brake caliper is the calibrated interface between driver intent and vehicle deceleration—translating pedal modulation into precise, repeatable stopping force with every application. Whether you’re shaving lap times or simply demanding absolute stopping confidence, it’s the component that ensures your braking system performs exactly when, and how, you command.