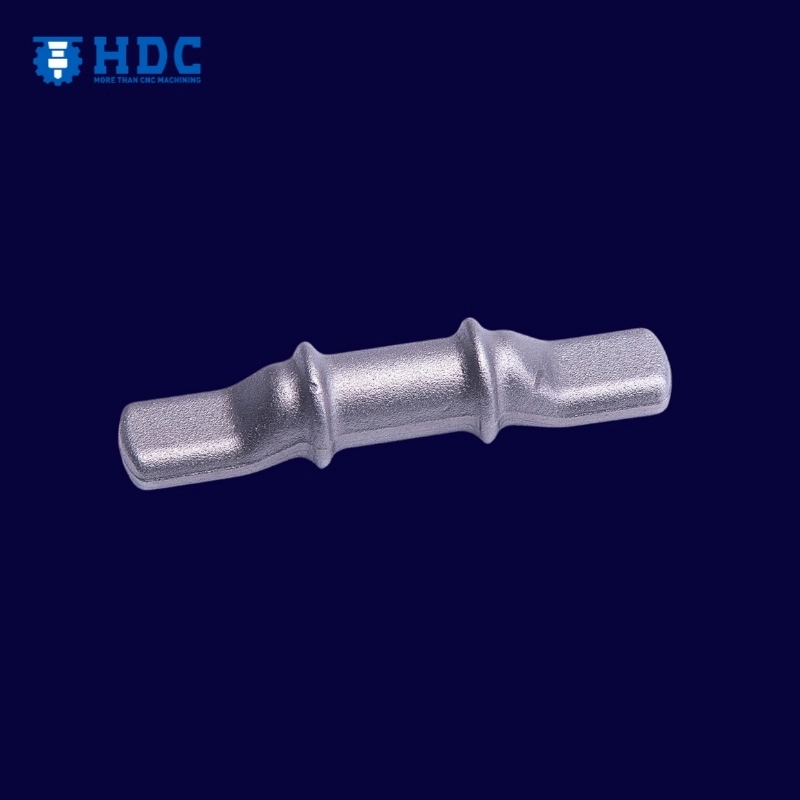

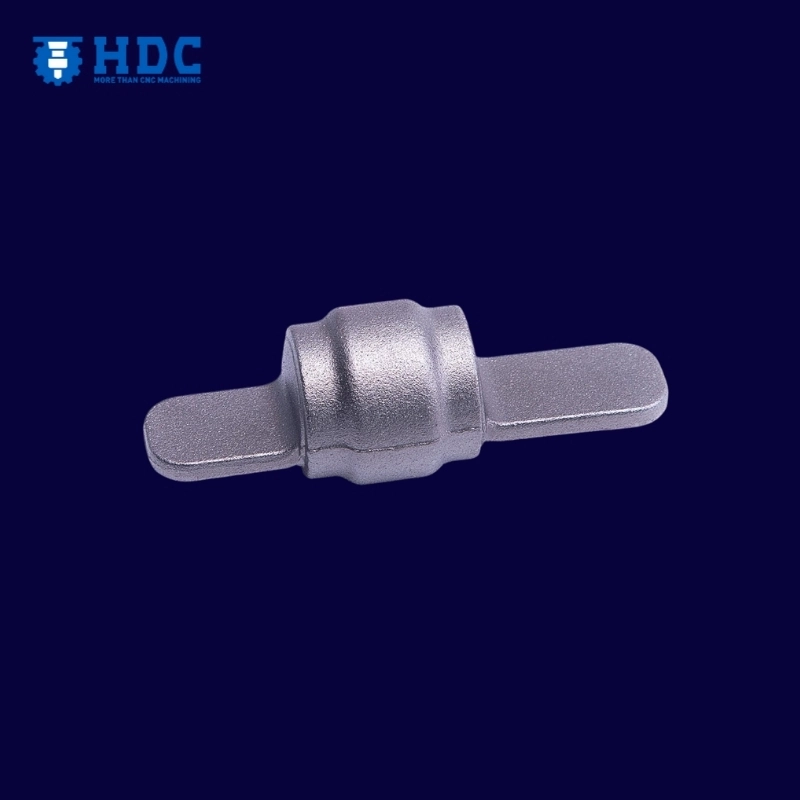

Maßgefertigter Pleuelrohling für Querlenker zur Herstellung von Autoaufhängungen

Details zu kundenspezifischen Produkten

| Modell Nr. | HDCACR001 |

| Stil | Geschmiedeter Pleuelstangenrohling |

| Material | Stahl, Stahllegierung, Aluminium, Aluminiumlegierung |

| Finish-Typ | Unbehandelt, poliert, eloxiert, elektrophoretisch beschichtet, pulverbeschichtet, galvanisiert, verchromt, schwarz oxidiert |

| Verfügbare Größe | / |

| Mindestbestellmenge | 100 Stk. |

| Benutzerdefiniertes Logo | Verfügbar |

| Herkunft | China |

| Verpackung & Lieferung | |

| Versandoption | Kurier-, Luft-, See-, Bahnexpress, EXW, FOB, CIF, DDU, DDP |

| Liefertermin | 25-30 Tage |

| Transportpaket | Kundenspezifisch, Karton, Palette |

Establish the unyielding foundation of your custom suspension components with this premium forged control arm connecting rod blank. Precision-engineered as a semi-finished machining substrate, this forging blank delivers metallurgically optimized grain flow and dimensional stability—providing professional fabricators and aftermarket workshops with a superior starting point for suspension link production.

Premium Steel Alloy Forging: Hot-forged from high-grade carbon or alloy steel, achieving dense, continuous grain orientation along critical load axes for exceptional fatigue resistance and structural integrity exceeding billet or cast alternatives.

Optimized Machining Allowance: Strategically configured with precision-controlled stock allowance at all critical interface locations, enabling final CNC profiling, drilling, and threading without compromising the forged grain structure.

Superior Grain Flow Integrity: Precision die-forging process aligns material fibers along the connecting rod’s longitudinal axis, delivering maximum tensile strength and deflection resistance under repeated suspension loading.

Versatile Component Foundation: Designed for secondary machining into a wide range of suspension control arms, track rods, radius arms, and chassis links—accommodating custom lengths, end configurations, and mounting geometries.

Aftermarket & Workshop Ready: Supplied in a consistent, heat-treated condition with scale-free surface preparation, ready for immediate fixturing and machining in professional fabrication environments.

Anwendungen:

Custom Suspension Fabrication: Ideal for motorsport workshops, restoration specialists, and chassis builders producing one-off or low-volume control arms with verified material integrity.

Aftermarket Performance Links: Suitable for manufacturers developing upgraded suspension components requiring certified forging quality and repeatable mechanical properties.

OEM Replacement Stock: Essential for high-stress applications where cast or fabricated links demonstrate fatigue failure under sustained load or impact cycling.

More than a raw blank, this forged connecting rod is the metallurgical genesis of suspension precision—preserving grain flow integrity through every subsequent machining operation. Whether you’re engineering a competition-grade control arm or reinforcing a heavy-duty chassis link, it’s the foundation that ensures your finished component performs exactly as specified.