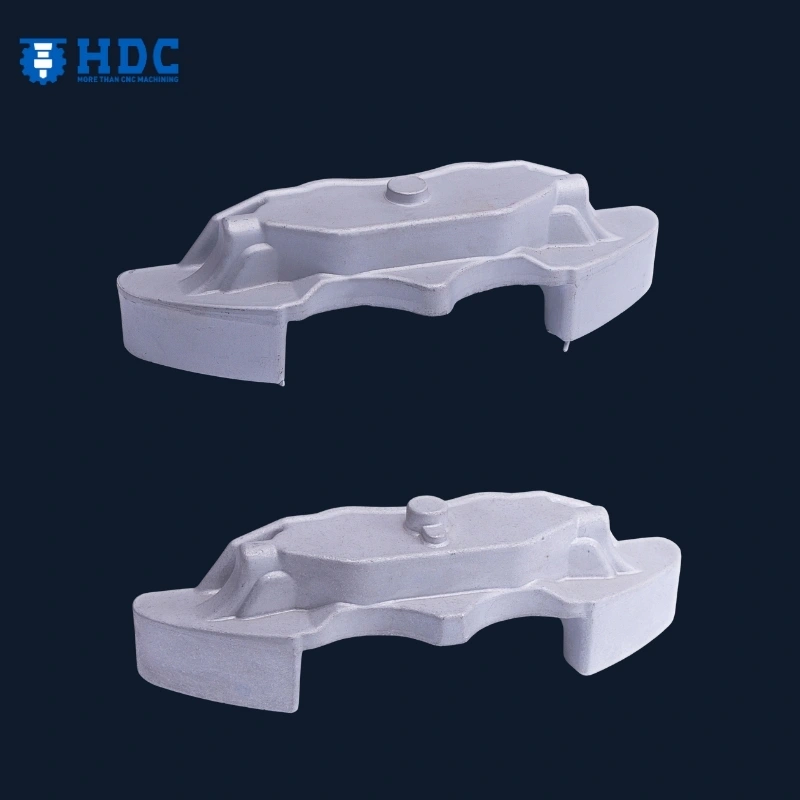

Präzisionsgeschmiedeter, exzentrischer Nocken aus Kohlenstoffstahl für Maschinenteile

Details zu kundenspezifischen Produkten

| Modell Nr. | HDCWCC001 |

| Stil | Geschmiedetes Exzenterrad |

| Material | Kohlenstoffstahl, Stahllegierung |

| Finish-Typ | Unbehandelt, poliert, eloxiert, elektrophoretisch beschichtet, pulverbeschichtet, galvanisiert, verchromt, schwarz oxidiert |

| Verfügbare Größe | / |

| Mindestbestellmenge | 100 Stk. |

| Benutzerdefiniertes Logo | Verfügbar |

| Herkunft | China |

| Verpackung & Lieferung | |

| Versandoption | Kurier-, Luft-, See-, Bahnexpress, EXW, FOB, CIF, DDU, DDP |

| Liefertermin | 25-30 Tage |

| Transportpaket | Kundenspezifisch, Karton, Palette |

Orchestrate precise mechanical motion under extreme cyclic loads with this precision hot-forged eccentric wheel and cylindrical cam. Engineered for high-load automation and transmission systems, this component translates rotational input into accurately timed linear or oscillating output—delivered with the grain-flow integrity only closed-die forging can provide.

Premium Carbon Steel Forging: Hot-die-forged from high-grade carbon steel, achieving continuous, unbroken grain orientation that follows the eccentric contour and cam lobe profiles—delivering superior fatigue resistance compared to billet-machined or cast alternatives.

5-Axis CNC Profile Fidelity: Finish-machined on 5-axis CNC equipment to maintain exacting profile accuracy, lobe timing, and concentricity tolerances critical for vibration-free, high-speed operation.

Surface Hardening Available: Optionally available with case hardening, induction hardening, or nitriding treatments—significantly increasing surface durability while preserving the forged core’s ductile toughness.

Fully Customizable Geometry: Manufactured to customer-specific profile developments, lift curves, and bore configurations—accommodating non-standard timing requirements, interface dimensions, and mounting integrations.

High-Load Cyclic Reliability: Engineered to withstand repetitive impact, continuous sliding contact, and elevated operating temperatures without premature spalling or geometric degradation.

Anwendungen:

Automation & Indexing Systems: Ideal for pick-and-place units, rotary tables, and cam-driven assembly machinery requiring precise, repeatable motion profiles under continuous duty cycles.

Industrial Transmission Systems: Suitable for heavy-duty conveyors, packaging equipment, and specialized drive mechanisms demanding high torque transmission and synchronized output.

Custom Mechanical Actuation: Essential for one-off machinery builds, retrofitted automation cells, or prototype development requiring non-standard cam geometry and verified material integrity.

More than a mechanical profile, this forged eccentric cam is the programmed interpreter of rotational energy—converting constant input into precisely metered output with every revolution. Whether you’re engineering high-speed packaging lines or heavy industrial actuation, it’s the component that ensures your motion profile remains accurate long after lesser parts have worn out of specification.