- Heim

- Ressourcen

- Bloggen

- CNC-Fräser vs. CNC-Fräse

CNC-Fräser vs. CNC-Fräse: Was ist das Richtige für Sie?

- Von: HDCMFG

Kennen Sie die Unterschiede zwischen CNC-Fräsen und CNC-Fräsen? Wissen Sie, wie beide funktionieren? Wie sie arbeiten und funktionieren? Egal, ob Sie überhaupt keine Ahnung haben, was das ist, oder ob Sie sich noch nicht sicher sind, ob das für Sie das Richtige ist, dies ist der perfekte Leitfaden.

Warum ist das der perfekte Leitfaden? Ganz einfach – denn in diesem Blog erklären wir es Ihnen im Detail! Wir definieren nicht nur CNC-Fräsen und CNC-Fräsen, sondern vermitteln Ihnen alles Wissenswerte über diese Maschinen!

Bevor wir tief in den Vergleich von CNC-Router vs. Fräsmaschine eintauchen

Was ist ein CNC-Fräser?

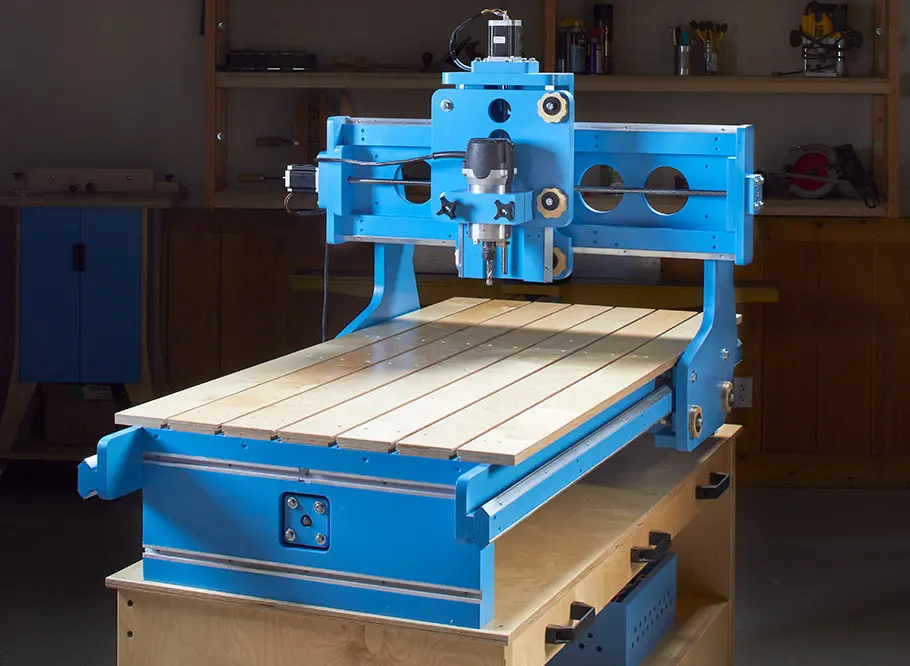

Quelle: Woodsmith-Pläne

Beginnen wir mit der Frage: Was ist eine CNC-Fräsmaschine? Was macht sie? Kurz gesagt: Eine CNC-Fräse ist genau wie eine herkömmliche Fräse. Der einzige Unterschied besteht darin, dass eine CNC-Fräse computergesteuert ist, sodass kaum bis gar kein menschliches Eingreifen erforderlich ist.

Wie Oberfräsen dienen sie zum Schneiden, Schnitzen und Formen verschiedener Materialien wie Holz, Kunststoff, Metall und Schaumstoff. Sie arbeiten entlang mehrerer Achsen und Linien, um präzise Designs basierend auf digitalen Anweisungen zu erstellen.

Wann benötigen Sie CNC-Fräser?

CNC-Fräser sind unverzichtbar, wenn Sie weichere Materialien wie Holz, Kunststoff und Aluminium schnell, präzise und effizient schneiden müssen. Sie eignen sich ideal für Branchen, in denen detaillierte Gravuren, Formgebungen und die Massenproduktion komplexer Designs erforderlich sind.

Unternehmen im Möbelbau, in der Schilderproduktion, im Schreinerhandwerk und im Prototypenbau nutzen CNC-Fräsen, um ihre Abläufe zu optimieren und die Konsistenz zu gewährleisten. Darüber hinaus nutzen auch die Automobil-, Architektur- und sogar die Verpackungsindustrie CNC-Fräsen!

Was ist eine CNC-Fräse?

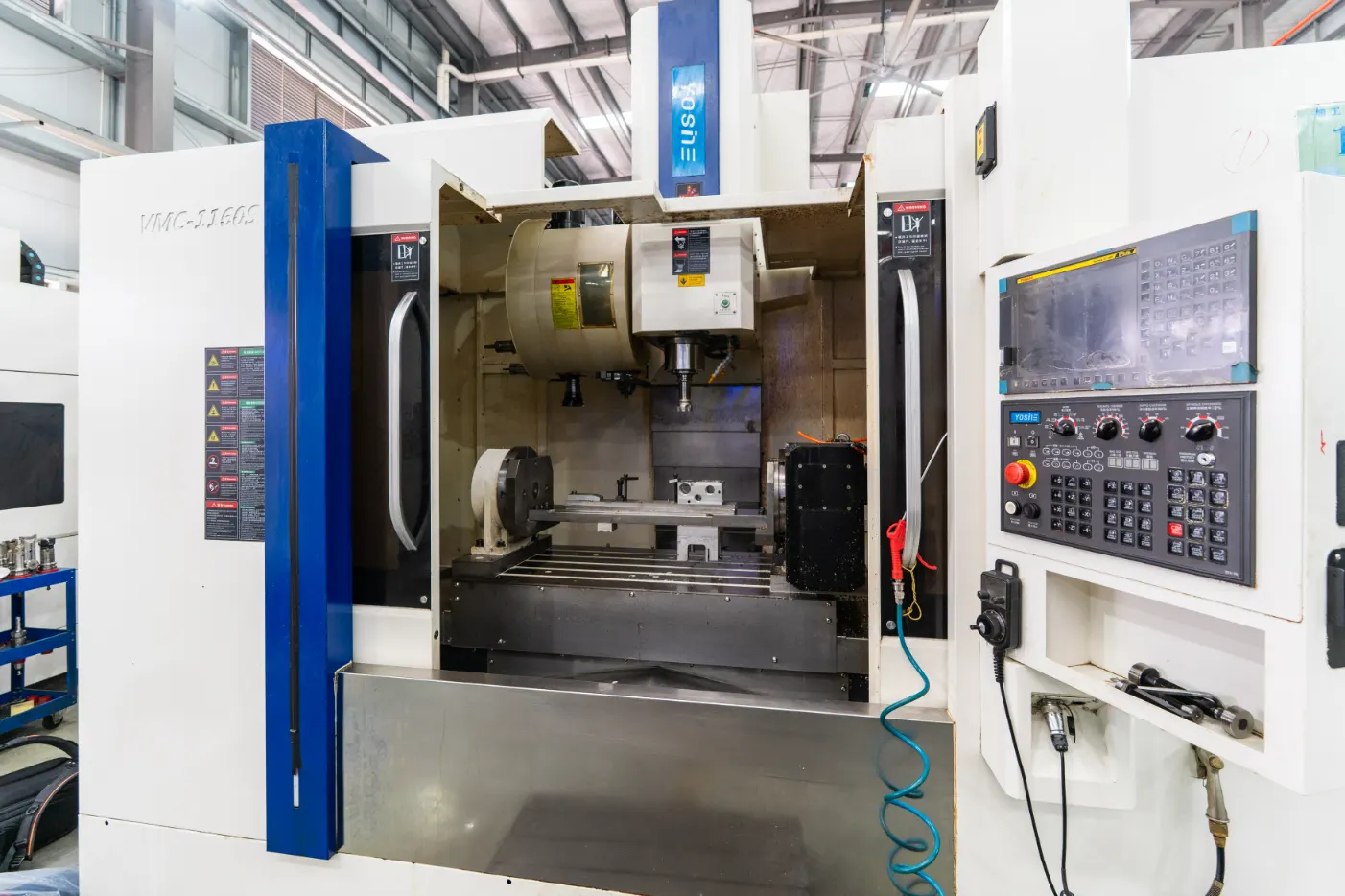

Quelle: Wertvolle Hardware

Am anderen Ende des Spektrums CNC-FräseWie ein CNC-Fräser ist auch eine computergesteuerte Fräse. Es handelt sich um eine Maschine, die präzise Material von einem Werkstück entfernt, um komplexe Teile herzustellen.

Sie arbeiten entlang mehrerer Achsen – üblicherweise X, Y und Z –, um verschiedene Vorgänge auszuführen, darunter Bohren, Ausbohren und Gewindeschneiden.

Beide gelten als wichtige Säulen der Fertigungswelt. Doch worin unterscheiden sie sich? Was macht sie einzigartig?

Wann benötigen Sie CNC-Fräsen?

CNC-Fräsen sind die beste Wahl für die hochpräzise Bearbeitung von Hartmetallen wie Stahl, Titan und Aluminium. Diese Maschinen sind für die Schwerzerspanung konzipiert und eignen sich daher ideal für Branchen, in denen Genauigkeit und Langlebigkeit entscheidend sind.

Im Gegensatz zu CNC-Fräsern, die weichere Materialien bearbeiten, sind Fräser darauf ausgelegt, tiefe Schnitte vorzunehmen und selbst unter hoher Belastung enge Toleranzen einzuhalten.

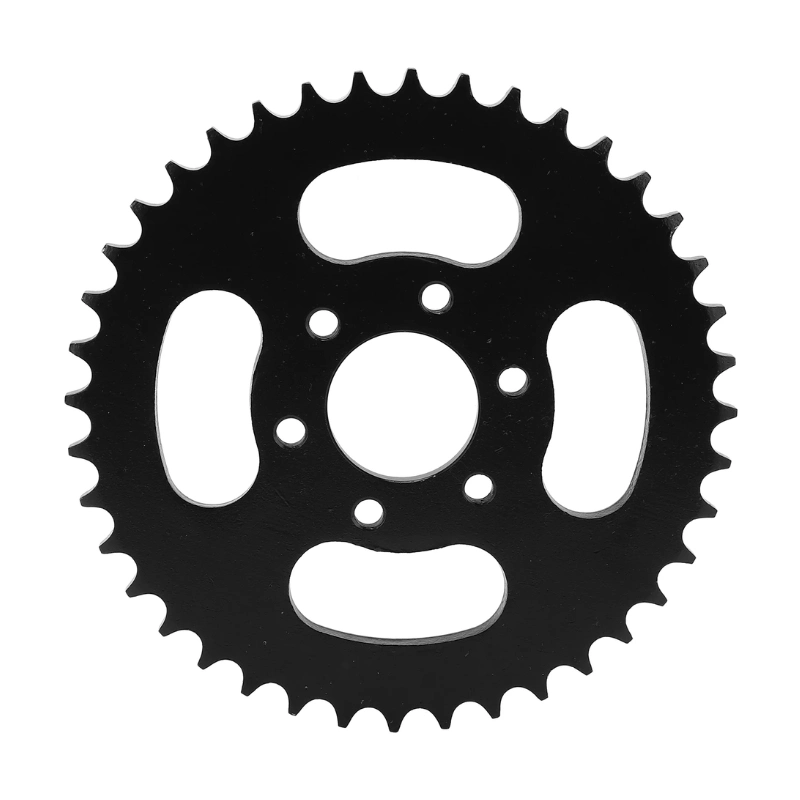

Verschiedene Branchen wie die Luft- und Raumfahrt, die Medizintechnik und die Automobilindustrie nutzen CNC-Fräsen zur Herstellung komplexer Motorteile, chirurgischer Instrumente, Präzisionszahnräder und anderer empfindlicher Komponenten. Darüber hinaus finden sie auch im Formenbau, in der Metallverarbeitung und im industriellen Prototyping breite Anwendung.

CNC-Fräser vs. CNC-Fräse: Welche Maschine ist für Sie besser geeignet?

Nachdem wir sie nun einzeln kennen, stellt sich die Frage, worin sie sich unterscheiden. Hier finden Sie eine Tabelle mit Informationen zu CNC-Fräsern und CNC-Fräsen.

In dieser Tabelle finden Sie die besten Informationen zu den beiden, damit Sie erkennen können, wo sie sich ähneln und wo sie völlig unterschiedlich sind.

| Besonderheit | CNC-Fräser | CNC-Fräse |

| Ideale Materialien | Am besten für weichere Materialien wie Holz, Kunststoff und Schaumstoff. | Geeignet für härtere Materialien wie Metalle, einschließlich Stahl und Titan. |

| Präzision | Bietet mittlere Präzision, geeignet für Aufgaben wie Schilderherstellung und Möbelherstellung. | Bietet hohe Präzision, die für komplizierte Teile in der Luft- und Raumfahrt sowie im medizinischen Bereich unerlässlich ist. |

| Schneidgeschwindigkeit | Arbeitet mit höherer Geschwindigkeit und ermöglicht so schnelle Schnitte auf großen Blättern. | Funktioniert bei niedrigeren Geschwindigkeiten, um Genauigkeit bei härteren Materialien zu gewährleisten. |

| Kosten | Im Allgemeinen sind sie günstiger und daher auch für kleine Unternehmen und Hobbybastler zugänglich. | Aufgrund ihrer robusten Konstruktion und erweiterten Funktionen sind sie in der Regel teurer. |

Wie Sie sehen, handelt es sich bei beiden um subtraktive Maschinen, die zur Herstellung bestimmter Komponenten für verschiedene Branchen und Projekte eingesetzt werden. Sie sind jedoch nicht gleich. Zwar handelt es sich um CNC-Schnitte ohne die Notwendigkeit eines Arbeiters, dennoch wären die Ergebnisse unterschiedlich.

HINWEIS: Dies sind die grundlegenden Unterschiede zwischen den beiden. Es ist nicht alles, aber diese kleinen Unterschiede machen in der Summe große Unterschiede aus.

Jedes hat seine eigenen Einsatzmöglichkeiten, Unterschiede in Geschwindigkeit, Präzision und idealen Materialien zum Schneiden und Bearbeiten. Schauen wir uns beide genauer und detaillierter an!

Materialien

Lassen Sie uns zunächst kurz über die Materialien sprechen. CNC-Fräser funktionieren am besten mit Holz, Kunststoff, Schaumstoff und dünnen Aluminiumblechen.

CNC-Fräsen hingegen sind für die Bearbeitung harter Materialien wie Stahl, Titan und Gusseisen ausgelegt und eignen sich daher ideal für anspruchsvolle Industrieanwendungen.

Entwurf

Die meisten, wenn nicht alle CNC-Fräser sind auf Geschwindigkeit und Effizienz ausgelegt. Leichte Rahmen eignen sich besser für weichere Materialien. CNC-Fräsen sind in der Regel schwerer und stabiler und für die Bearbeitung härterer Materialien ausgelegt. Gleichzeitig reduzieren sie Vibrationen und ermöglichen präzises Schneiden.

Schauen Sie sich dieses Video an! Neben Oberfräsen und Fräsen gibt es auch CNC-Drehmaschinen! Entdecken Sie die Unterschiede bei CNC-Fräsen!

Einsatzgebiet

Oberfräsen haben typischerweise einen größeren Schnittbereich und eignen sich daher ideal für die Bearbeitung breiter Platten aus Holz, Kunststoff und Aluminium. Fräser haben einen kleineren Arbeitsbereich, können aber dickere und dichtere Materialien mit höherer Genauigkeit schneiden.

Geschwindigkeit

Oberfräsen schneiden weiche Materialien schneller, da sie mit höheren Drehzahlen laufen. Tiefe, präzise Schnitte in Hartmetallen ermöglichen Fräser, die zwar langsamer laufen, aber mehr Leistung bieten.

Kosten

CNC-Fräser sind günstiger; Einstiegsmodelle sind bereits für wenige Hundert Dollar erhältlich. CNC-Fräsen, insbesondere solche in Industriequalität, sind aufgrund ihrer erweiterten Funktionen und ihrer Langlebigkeit deutlich teurer.

Werkzeuge

Und schließlich die benötigten Werkzeuge. CNC-Fräser verwenden Fräser, die zum Formen, Gravieren und Schneiden weicher Materialien entwickelt wurden. CNC-Fräser verwenden Schaftfräser, die höchste Präzision beim Konturieren, Schlitzen und Profilieren härterer Metalle bieten.

Ist Fräsen dasselbe wie Routing?

Fräsen und Fräsen mögen ähnlich erscheinen, dienen aber unterschiedlichen Zwecken. Um einen genaueren Vergleich zu ziehen: Fräsen dient zum Schneiden harter Metalle mit höchster Präzision, während Fräsen hauptsächlich zum Formen von Holz, Kunststoff und weichen Metallen dient.

Darüber hinaus verwenden Fräser starre, hochbelastbare Maschinen, um tiefe Schnitte zu erzielen. Oberfräsen hingegen arbeiten mit höheren Geschwindigkeiten für schnelle, flache Schnitte.

Die kurze Antwort lautet: Wenn Sie harte Materialien präzise bearbeiten müssen, ist Fräsen die richtige Methode, während sich Fräsen besser für die Produktion von Leichtbauteilen, weichen Werkstoffen und hohen Geschwindigkeiten eignet.

Warum HDC das #1 CNC-Bearbeitungsunternehmen ist, mit dem Sie zusammenarbeiten werden

Wir hier bei HDC Wir präsentieren unser Know-how in der Fertigungsindustrie, indem wir die besten und hochwertigsten Komponenten herstellen, sei es Kunststoff, Holz, Metalle oder sogar spezielle Legierungen wie Titan, Nickel, Kupfer, und mehr!

Falls Sie sich nicht sicher sind, wie viel Budget Sie benötigen, Kontaktieren Sie uns! Wir senden Ihnen einen kostenlosen Kostenvoranschlag zu!

Ressourcen:

Entdecken Sie mehr mit unseren Blogbeiträgen.

kürzliche Posts

Erfahren Sie mehr über unsere Produkte.

Verwandte Produkte

Sofortiges Angebot!