In the world of metals tin vs. aluminum is the comparison that a lot of people still don’t get. No matter how experienced some people are, no matter how deep they are in the industry, they’re still clueless as to whether they should use aluminum or tin.

That’s why in this article, we did due diligence. We did heavy research to help you identify and tackle some of the areas that you’ve been missing. We’ll discuss tin and aluminum and we’ll try to get you all the information you want and you’re looking for.

What is Tin?

Quelle: Amazon

Tin is one of those metals that’s soft, malleable, and commonly used for a wide range of applications. Furthermore, it’s an element, which means that its contents cannot be broken down into simpler substances.

In terms of physicality, tin is silvery white and is often used to combine or coat other metals to prevent unwanted reactions like corrosion.

Was ist Aluminium?

Quelle: Designing Buildings

Like tin, aluminum is this white, silver-like metal that is almost instantly recognizable. In addition, aluminum is also the most abundant metal on earth, making up about a little over 8% of the Earth’s crust.

Aluminum is highly durable, strong, and is a great heat conductor. That is why they’re used in many different industries for parts and components.

Also Read: Leitfaden zu 5 Edelstahlsorten: Eigenschaften, Güteklassen und Anwendungsbereiche

Is Tin Better Than Aluminum?

Yes and no–let me explain why. Both metals have this sense of functionality, where people consider them more effective in a certain level or aspect.

People consider tin better because it’s more durable and offers durability and corrosion resistance. Aluminum, on the other hand, is a lot cheaper, more available, and lightweight.

So, the advantages of aluminum versus tin is different and vice versa.

Tin vs. Aluminum: Everything You Need to Know

When deciding between tin and aluminum, there’s no universal “better” metal. What that is would be the metal better fit for your application. From strength and corrosion resistance and conductivity, tin and aluminum serve distinct roles across manufacturing, packaging, and electronics.

Let’s break down their differences by key material properties to help you choose the right one.

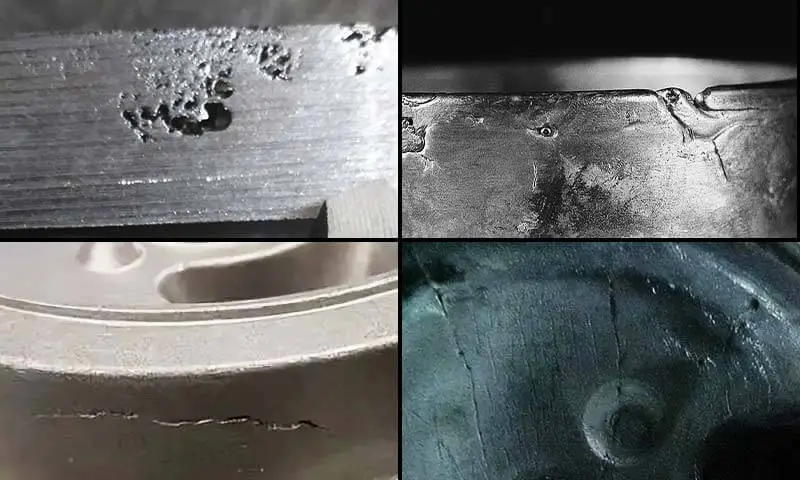

Korrosionsbeständigkeit

Quelle: Monroe Engineering

The first and probably one of the most important pieces is corrosion resistance. Aluminum naturally forms a self-repairing oxide layer protecting it from rust and corrosion. This makes it ideal for structural, marine, and outdoor environments.

Tin, in that same place, also resists corrosion, particularly in neutral or mildly acidic settings. However, unlike aluminum, tin is commonly used as a protective coating to prevent rust on steel.

Stärke

When it comes to metals, strength and hardness are two important factors. So, let’s not avoid talking about this.

Aluminum is lightweight but durable and strong, especially in specifically alloyed forms like 6061 or 7075. The high strength-to-weight ratio makes it ideal for aerospace, construction, and automotive use.

On the other hand, tin is much softer and weaker than aluminum. Generally, tin is not suitable for structural load-bearing. However, its softness benefits applications like alloying, coating, and soldering.

Malleability

Both metals are flexible and malleable enough, but tin takes the win as it is easier to form into challenging intricate shapes. Furthermore, they’re ideal for coatings and decorative items.

Aluminum also offers excellent workability and maintains strength after forming, making them perfect for structural panels, packaging, and extrusions.

Temperaturbeständigkeit

Aluminum has a high melting point (660°C), allowing it to withstand high-temperature environments such as engine components and heat exchangers. This is one of the main reasons why people often choose aluminum over tin in applications that are expected to have high temperatures.

Tin, however, has a much lower melting point (232°C). This makes them the least ideal and unsuitable for high-heat applications. But, combining this feature with ideal for soldering and thermal bonding.

Mehr lesen: Schmieden vs. Rohmaterial: Welches Verfahren ist 2026 stärker, günstiger und besser?

Sustainability and Cost

And last but most definitely not least, of course, is the cost. Aluminum is more abundant, cost-effective, and infinitely recyclable.

Tin is less available, more expensive, and has a less energy-efficient recycling process. Paving the road of reason why most people, especially those in business choose aluminum over it.

Tin vs. Aluminum Foil: Are They the Same?

To answer the question, no, they’re not the same. You might hear people calling aluminum foil “tin foil” because originally, food packaging cover foils are made from tin.

Therefore, the term “tin foil” that people use today was just a stuck terminology because people got used to it. But, it’s best that you know that tin foil and aluminum foil are two different things.

Refer to the differences of aluminum and tin above to get a better sense of how they’re distinct and different from one another!

HDC as the Best Tin and Aluminum Manufacturer in China

Tin vs. Aluminum? You pick your champion. Consider their properties and characteristics, and make the better choice depending on what your needs are. No matter what your decision is, you can count on us here at HDC to help you with it.

Armed with the best and highest forms of technology, we’re more than ready to supply you with whatever metal you’re looking for; tin, copper, aluminum, stainless steel–you name it.

Other than manufacturing metal, we’re also skilled to perform machining services to help you curate the exact component you need.

What are you waiting for? Contact us today and get a free quote!