Custom Forged Heavy Duty Hinge Supplier in China

HDC forges high-strength metals into heavy-duty hinges for global industries, including transportation, machinery, marine, and more.

Forged Hinge Types

HDC produces a wide range of forged hinges. We can forge hinges based on your drawing or samples.

Container Door Hinge

HDC manufactures the container door hinge by forging carbon steel, which can easily handle heavy container doors and is suitable for weld-on installation.

Trailer Ramp Hinge

With forging, HDC fabricates trailer ramp hinges with extreme high strength for heavy load requirements; additional features like a grease fitting are also available.

Car Door Hinge

Different from standard hinges, car hinges vary depending on the car model. HDC is capable of customizing special-shaped car hinges according to your design.

Heavy Duty Gate Hinge

Whether it’s a fence gate that weighs kgs or a heavy-duty explosion-proof door that weighs tons, you can count on HDC’s forging capability to produce hinges for them.

Truck Door Hinge

HDC fabricates a wide range of hinges for trucks, including tailgate hinges, sideboard hinge, and rear door hinges. We forge for durability and CNC for smooth operation.

Forged Strap Hinge

With a long leaf, the strap hinge has a larger supporting surface area and better load distribution, making it suitable for heavy doors. With forging, HDC can further enhance its loadbility

Forged Bullet Hinge

The bullet hinge is usually welded to the door and has a grease fitting for lubrication. We forge the blank and CNC drill for perfectly aligned pin holes and grease fittings.

Forged Butt Hinge

HDC forges the butt hinge to make it bear more weight and shear forces, and is less prone to deformation or breakage under heavy loads compared to cast or stamped hinges.

Forged Flag Hinge

The flag hinge is commonly used on gates and shutters. HDC forges the pin and leaves of it to enhance its resistance against leverage and ensure long-term integrity.

Forged Weld On Hinge

Designed for permanent installation, weld-on hinges are a robust solution. We forge these hinges for maximum strength and precision, making them perfect for heavy-duty applications.

Forged Hinge Pin

The pin is the core bearing component of any hinge. HDC custom-forges pins with high-grade steel to maximize tensile strength and rotational fatigue life under high load.

Forged Lift Off Hinge

The lift-off hinge is designed for quick, tool-free door removal. We utilize forging to produce the two separating components, ensuring easy installation and high load capacity.

Why Choose HDC

Why should you trust HDC for a forged brake lever? Here is the answer.

High Strength Forging

Our forging press’s capabilities range from 160T to 4000T, enabling us to forge most metals for your custom hinges.

Mass Production Capability

With over 30 forging machines and the automated forging line, HDC can produce forged hinges up to 10,000 per month.

Wide Range of Material

HDC forges hinges with a wide range of metals, including aluminum, stainless steel, and carbon steel. Other materials are also negotiable

Comprehensive Service

We provide design optimization support, multilingual service, and import assistance, making it as easy as sourcing nearby.

How HDC Manufactures Forged Hinges

Learn more about HDC’s capabilities in forging heavy-duty hinges.

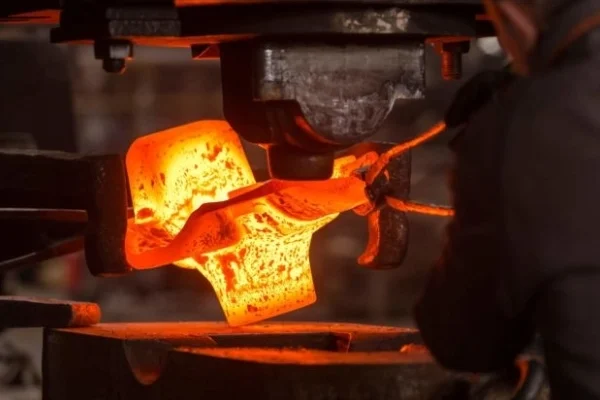

Forging Hinge Billet

First, we forge the metal block into a near-net shape close to the final hinge shape through closed-die forging.

Heat Treatment for Hinge

Heat treatment is an important process next to forging; we utilize tamping, aging, normalizing, etc, to enhance properties of the hinges.

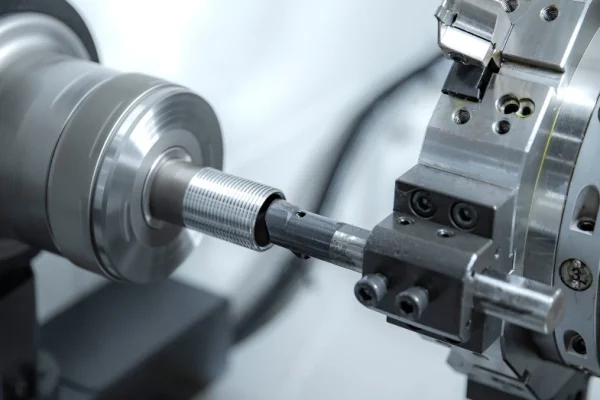

Milling and Drilling

For a specific design of hinge that requires precision-drilled mounting holes, HDC finishes it with in-house CNC machining capabilities.

Check out our quality control methods for forging parts.

Forged Hinge Materials

Our comprehensive material options can satisfy all your needs for a forged hinge.

When properly forged, carbon steel hinges offer superior load-bearing capacity at a highly cost-effective price point. This makes it the most common choice for forged hinges that need to handle heavy doors, frequent impact, or outdoor working conditions. To further enhance its corrosion resistance, HDC can apply a protective surface, like zinc or powder coating.

The carbon steel that HDC offers includes Q355B and Q235.

Aluminum can be easily formed into complex-shaped hinges by hot forging and cold forging. Both processes are HDC’s specialty. These forged aluminum hinges are light yet exceptionally strong, perfect for light-duty doors, equipment covers, or mobility devices. The finishing options for aluminum are also very mature, giving you full freedom to customize the appearance.

HDC offers forged aluminum hinges in aluminum alloy 6061, 6063, and 7075.

Stainless steel is more expensive than carbon steel and aluminum alloy due to its higher material cost and more challenging forging process. However, stainless steel remains a premium choice for hinges used in marine equipment, modern buildings, and other applications.

HDC can forge stainless steel hinges using 304 and 316, depending on your corrosion-resistance needs.

Available Finishes for Forged Hinge

No matter what finishes you need for a forged hinge, HDC has you covered.

Polishing helps remove minor surface marks from forging and makes stainless steel or aluminum look noticeably more premium. While polishing improves appearance, it doesn’t provide protective coating on its own. For outdoor use, we recommend combining it with additional surface treatments.

Powder coating is one of the most durable and colorful finishes for forged hinges. It adds a tough protective layer that resists corrosion, weather, and scratches, making it ideal for equipment, vehicles, and outdoor structures.

HDC provides nearly unlimited powder coating color options. The finish options include smooth, matte, gloss, and textured surfaces

Zinc coating is widely used to protect carbon steel hinges from rust. Thin-layer zinc plating is suitable for general applications, while hot-dip galvanizing provides a much thicker, longer-lasting protective layer for harsh conditions. Zinc coating is mainly used for carbon steel hinges due to compatibility with the base material.

Technical Specifications

Discover the range of HDC’s custom forging hinge capabilities.

| Forging Method | Closed-die forging(hot forging and cold forging) |

| Max Forging Size | Up to 400 mm overall hinge length (depending on design) |

| Weight Range | 50 g – 30 kg per hinge assembly |

| Forging Tolerance | ±0.3 mm–±0.5 mm (depending on geometry) |

| Weld-on Compatibility | Yes — optimized forging design for weld-on hinges (especially carbon steel) |

| Production Volume | From small batch prototypes to mass production (10,000+ pcs/month) |

| Tooling / Mold | In-house tooling design & fabrication; rapid sampling available |

| Machining Support | CNC milling, drilling, turning, reaming, bushing installation |

| Assembly Options | Pin installation, greasing grooves, tolerance-controlled mating parts |

| Inspection & Testing | Dimensional inspection, hardness test, tensile test, salt spray test (available on request) |

| Design File Support | STEP, IGES, STL, PDF drawings |

Need Custom Forged Hinges?

Reach out to HDC, then you get the most expert one-stop forging product solution you can find. Just send an email, our quote is free!

FAQ

What is a forged hinge?

A forged hinge is made by shaping heated metal under high pressure. This gives the hinge a very dense structure and excellent strength. They’re commonly used for heavy doors, ramps, and equipment that need long-term reliability.

Which are the strongest: forged, cas,t or stamped hinges?

Forged hinges are the strongest. Casting can make complex shapes but is not as solid internally, and stamping is mainly for lighter-duty parts. If you need something that can handle impact and heavy loads, forging is the best option.

What materials are best for forged hinges?

Carbon steel is the go-to material for strength. Stainless steel is chosen for corrosion resistance and a clean appearance, especially outdoors. Aluminum works well when weight reduction matters.

What is the difference between a forged hinge and a cast hinge?

Forged hinges are pressed into shape, so the metal fibers stay tight and strong. Cast hinges are made by pouring molten metal into a mold, which can create internal porosity. In most heavy-duty applications, forged hinges last longer and handle stress better.

How are forged hinges manufactured?

The process is simple: cut the raw material, heat it, forge it into shape, trim it, then machine and finish it. Forging gives the basic strength, and machining ensures the final precision. Coatings like zinc or powder help protect the surface.

Can forged hinges be welded?

Yes, especially carbon steel hinges—they’re commonly used as weld-on hinges. Stainless steel and aluminum can also be welded with the right technique. Just match the welding method to the material.

Do forged hinges require heat treatment?

Not always, but many carbon steel hinges benefit from heat treatment to improve strength and durability. Aluminum and stainless steel depend more on the specific alloy. Your requirements decide whether heat treatment is needed.