Enhance Your Vehicle with Aluminum Wheel Spacers: Style and Performance

Transform the look and feel of your vehicle with aluminum wheel spacers. This blog explores the advantages of aluminum wheel spacers, including improved handling, fuel efficiency, and aesthetic appeal. Learn about the installation process, safety considerations, and how to choose the right size and finish. Dive into the world of custom aluminum wheel spacers and find out how they can elevate your ride with enhanced performance and style.

Advantages of Aluminum Wheel Adapters

Aluminum wheel adapters provide a range of advantages, including significant weight reduction for improved fuel efficiency and handling. Their inherent corrosion resistance ensures durability in various environmental conditions. With a sleek appearance and easy customization, aluminum adapters offer aesthetic appeal and versatility. The ease of installation, cost-effective manufacturing, and overall durability make them a practical choice for enhancing vehicle performance and style. However, users should prioritize proper installation and compatibility with their specific vehicle to ensure optimal safety and functionality.

Aluminum vs. Other Materials

When deciding between aluminum and other materials for wheel adapters, consider factors such as weight, corrosion resistance, and heat conductivity. Aluminum’s lightweight nature improves fuel efficiency and handling, while corrosion resistance enhances durability. Alternatively, materials like steel offer robust strength, suitable for heavy-duty applications. The choice depends on specific requirements, including cost, customization options, and aesthetic preferences, based on the intended use and desired performance characteristics of the vehicle.

Types of Aluminum Alloy for Wheel Adapter

Various aluminum alloys are commonly used in wheel adapter manufacturing, each with specific properties:

- 6061 Aluminum Alloy:Known for corrosion resistance, weldability, formability, and high strength.

- 7075 Aluminum Alloy:Exceptional strength, suitable for high-stress applications, commonly used in performance or racing.

- 6063 Aluminum Alloy:Chosen for excellent extrudability, ideal for intricate shapes, and used in applications where aesthetics matter.

- Aluminum-magnesium alloys (5000 Series):g., 5052, 5083, offer good strength and corrosion resistance, commonly used in marine applications.

- Aluminum-Silicon Alloys (4000 Series):g., 4047, known for good fluidity during casting, suitable for casting applications in wheel adapter production.

- A356 Aluminum Alloy:Frequently used in casting processes, providing good castability and heat resistance.

Manufacturers choose alloys based on specific wheel adapter requirements, considering factors such as strength, corrosion resistance, and the preferred manufacturing process. The selection aims to achieve an optimal balance of properties for various applications.

Finishes for Aluminum Wheel Adapter

Aluminum wheel adapters can undergo various finishes for enhanced appearance and performance. Common finishes include:

- Anodizing for increased durability and color options

- Powder coating for toughness and diverse colors

- Polishing for a sleek appearance

- Painting for versatile color choices

- Chrome plating for a classic look

- Clear coating for natural appearance protection

- Bead blasting for a non-reflective texture

- Brushed finish for aesthetic appeal and uniqueness.

The choice depends on factors such as aesthetics, performance, and usage requirements.

Manufacturing Methods of Aluminum Wheel Adapters

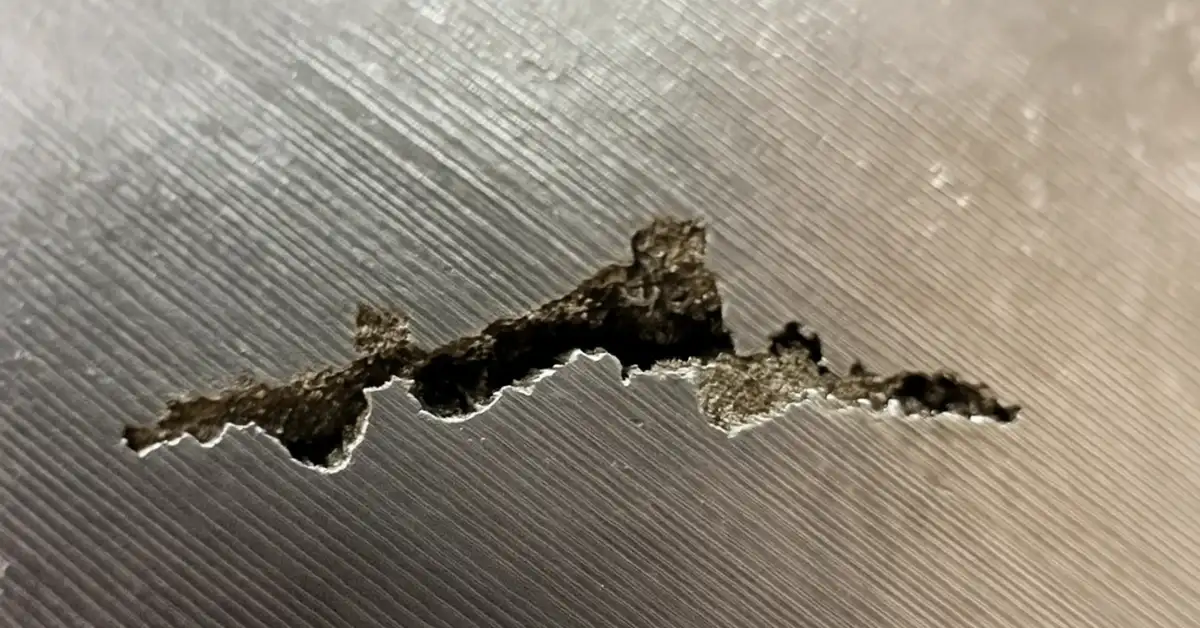

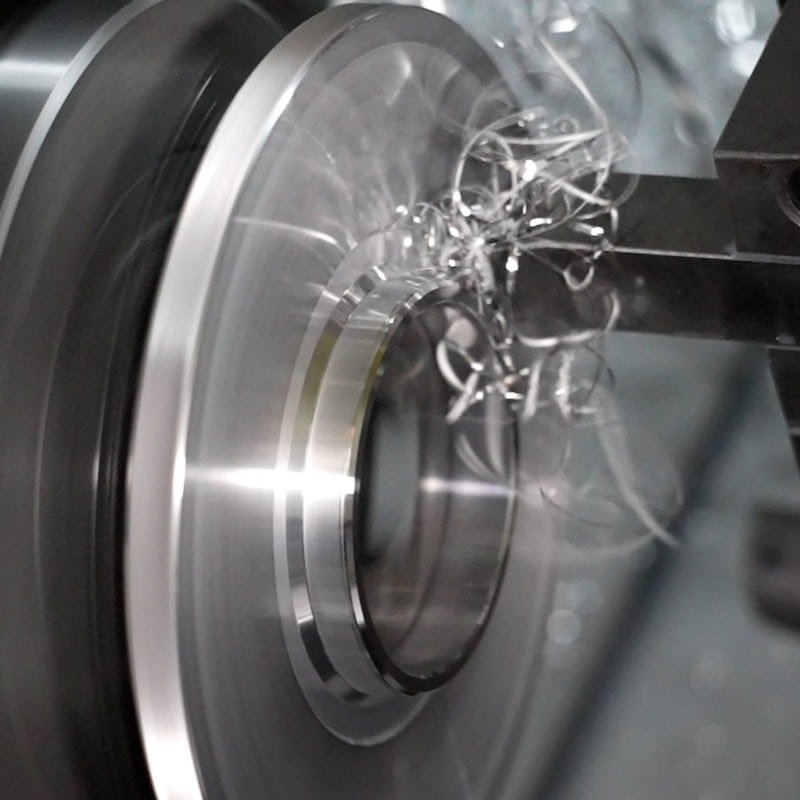

The production of aluminum wheel adapters typically involves a combination of two or more manufacturing processes. For instance, forging is employed to shape aluminum blocks into rough blanks, which are then precision-machined using CNC technology. Alternatively, the wheel adapter can be cast through casting methods and subsequently undergo CNC processing for refined surface treatment. The following are commonly used processes for machining wheel adapters and their respective advantages:

- CNC Machining from Billet:High precision, and flexibility, suitable for low to medium production.

- Casting:Suitable for complex shapes, potentially lower costs for large quantities.

- Forging:Improved material strength, suitable for high-stress applications.

Safety Considerations of Aluminum Wheel Adapter

Ensuring the safety of aluminum wheel adapters is vital. Key considerations include using high-quality materials, proper sizing, hub-centric design, adherence to bolt patterns and stud sizes, following torque specifications, regular inspections, verifying load-bearing capacity, professional installation, ensuring sufficient thread engagement, avoiding extreme modifications, considering driving conditions, complying with legal standards, following manufacturer recommendations, and educating users on proper care. These measures collectively contribute to safe wheel adapter usage and minimize potential risks.

Choosing the Right Size

Selecting the correct size for aluminum wheel adapters is crucial for both safety and proper vehicle performance. Here are essential steps to guide you in choosing the right size:

- Identify your vehicle’s specifications.

- Understand the required dimensions and wheel specifications.

- Verify bolt pattern, stud size, and hub diameter compatibility.

- Choose the right thickness for proper wheel alignment.

- Ensure sufficient thread engagement for lug nuts or bolts.

- Consult manufacturer guidelines and seek professional advice.

- Consider potential future upgrades.

- Perform a test fitment before finalizing the purchase.

- Review local regulations on wheel modifications.

By carefully considering these factors, you can confidently choose the right size aluminum wheel adapter for your vehicle, ensuring a safe and well-matched modification.

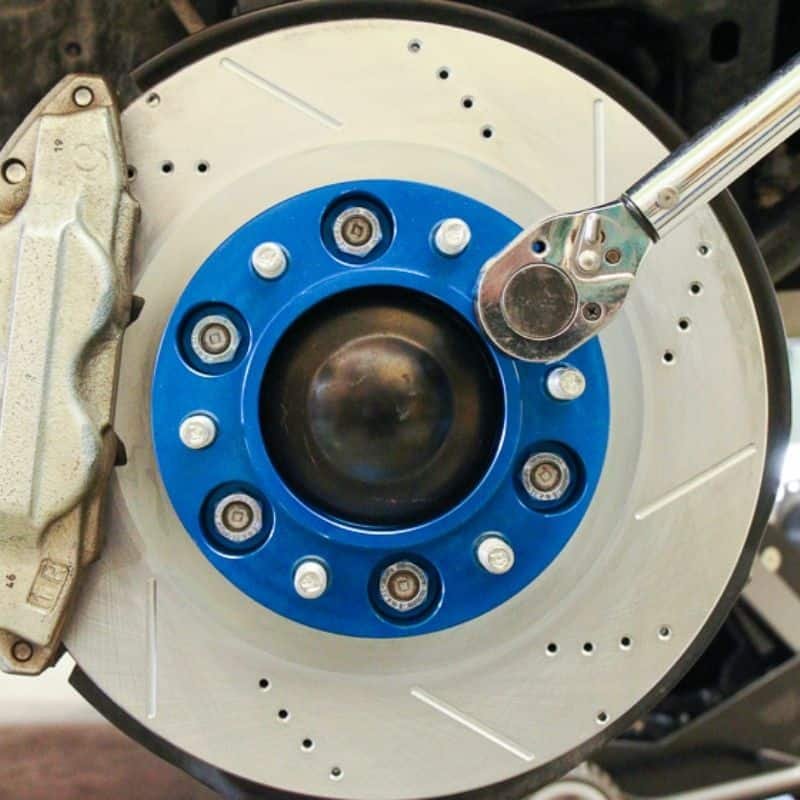

Installation and Maintenance

When installing aluminum wheel adapters, begin by selecting the correct size and type, ensuring a matching bolt pattern and hub diameter. Clean the mounting surfaces thoroughly, place the adapter onto the hub, and mount the wheels, gradually tightening lug nuts in a star pattern according to the manufacturer’s torque specifications. After a short drive, recheck the torque, and periodically inspect for wear or damage. Regularly clean and lubricate, and follow proper torque procedures after wheel removal. Address any issues promptly and adhere to the manufacturer’s guidelines for specific maintenance recommendations.

Custom Aluminum Wheel Adapters

If you’re looking to purchase custom aluminum wheel adapters from a manufacturer, there are several steps you can take to find a reputable supplier and ensure that you get the right product for your needs. Here’s a guide to help you through the process:

- Measurements:Know the specifications you need, such as bolt pattern and thickness.

- Research:Find manufacturers specializing in custom wheel adapters online.

- Check Reviews:Read customer reviews for insights into product quality and service.

- Contact Manufacturers:Inquire about customization options, pricing, and lead times.

- Samples or Prototypes:Request samples to assess product quality before bulk ordering.

- Certifications:Confirm the manufacturer complies with industry standards.

- Get Quotes:Obtain quotes from multiple manufacturers and compare prices.

- Review Terms:Check terms and conditions, including warranties and return policies.

- Payment and Delivery:Clarify payment terms and discuss expected delivery times.

- Communication:Maintain open communication throughout the process.

Remember that when dealing with custom products, clear communication is crucial to ensure that the manufacturer understands your specific requirements. Always prioritize reputable manufacturers with positive reviews and a track record of delivering quality products.

Conclusion

Aluminum wheel spacers offer a blend of style and performance for automotive enthusiasts looking to enhance their ride. From improved stability to a customized appearance, these accessories are making waves in the automotive world. Consider the factors discussed in this article to make an informed decision about whether aluminum wheel spacers are the right modification for your vehicle. Get ready to transform your driving experience with aluminum wheel spacers – a small change that makes a big impact.