Galvanized Steel and Stainless Steel are two of the most commonly used materials in the industry. Both metals/alloys are renowned for their strength and corrosion resistance, however, there are certain differences that make each uniquely suited for specific purposes. This article will provide a comparison between galvanized steel and stainless steel in terms of composition, manufacturing techniques, advantages and disadvantages of each type and the application of each material based on their unique set of characteristics.

What is Galvanized Steel?

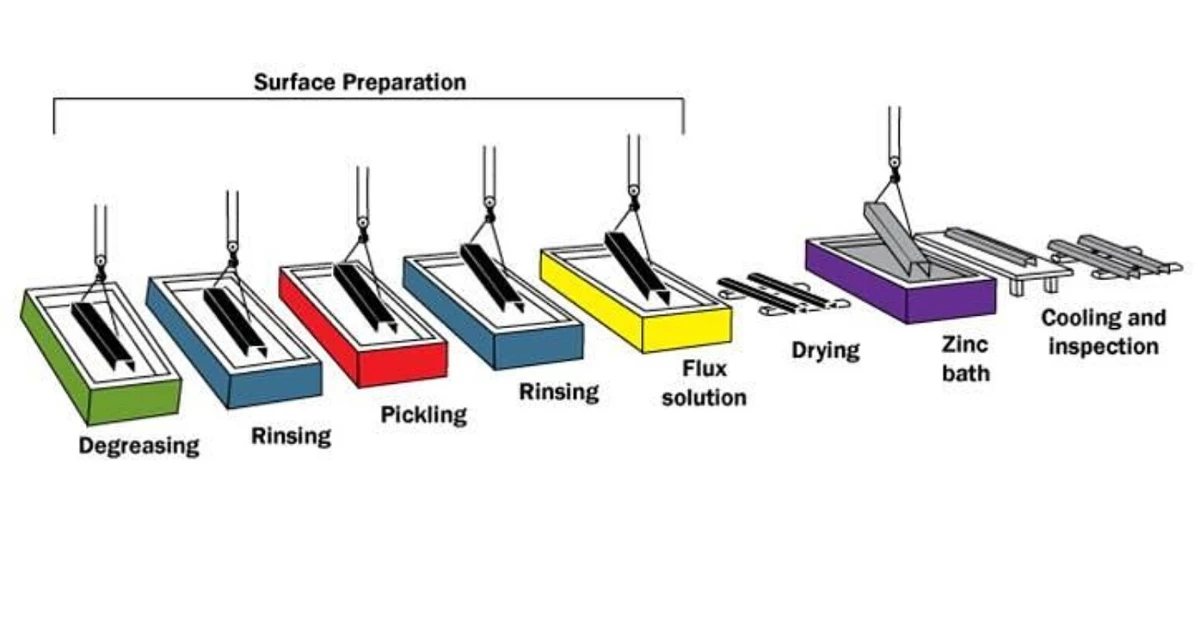

Galvanized steel is created by coating ordinary carbon steel with a protective layer of zinc, typically through a process called hot-dip galvanization. The zinc acts as a sacrificial barrier, protecting the underlying steel from rust and corrosion. If the coating is scratched or damaged, the zinc continues to provide protection by corroding first, effectively delaying rust formation on the steel itself.

Key Features of Galvanized Steel

- Corrosion Resistance: The zinc layer offers strong resistance to rust in mild environments.

- Cost-Effectiveness: Galvanized steel is relatively inexpensive compared to stainless steel.

- Versatility: Its durability and affordability make it suitable for a wide range of applications, from outdoor structures to automotive parts.

However, galvanized steel is not invincible. Prolonged exposure to harsh environments—such as marine or chemical settings—can degrade the zinc layer, leaving the underlying steel vulnerable to corrosion.

What Is Stainless Steel?

Stainless steel is an alloy composed of iron, at least 10.5% chromium, and often additional elements such as nickel, molybdenum, or manganese. The chromium content creates a thin, passive oxide layer on the surface that resists corrosion. Unlike galvanized steel, this corrosion resistance is intrinsic to stainless steel and does not rely on a coating.

Key Features of Stainless Steel

- Superior Corrosion Resistance: Stainless steel can withstand extreme conditions, including high humidity, saline environments, and chemical exposure.

- Strength and Durability: With its high tensile strength and resistance to wear, stainless steel is a long-lasting material for demanding applications.

- Aesthetic Appeal: Its shiny, polished finish makes it a favorite for architectural and decorative uses.

Stainless steel is available in various grades, each with specific properties. A few of the stainless steel grades we discuss in this article are as follows:

- 304 Stainless Steel: A versatile, corrosion-resistant grade used in kitchen appliances and outdoor furniture.

- 316 Stainless Steel: Contains molybdenum for enhanced corrosion resistance in marine environments.

- 440 Stainless Steel: A high-carbon grade known for exceptional hardness, often used in tools and knives.

- 18/10 Stainless Steel: Commonly used in cookware, this grade contains 18% chromium and 10% nickel for excellent durability and shine.

Galvanized Steel vs Stainless Steel: Head-to-Head Comparison

1. Corrosion Resistance

Stainless steel outperforms galvanized steel in corrosion resistance. Its chromium-based passive layer remains effective even if scratched or exposed to harsh environments. For example:

- 304 Stainless Steel: Offers general corrosion resistance and works well in most environments.

- 316 Stainless Steel: Resists corrosion even in highly saline or chemical-rich conditions.

In contrast, galvanized steel’s zinc coating provides temporary protection. Once the zinc layer is damaged or wears off, the underlying steel is susceptible to rust.

Verdict: Stainless Steel offers better corrosion resistance than Galvanized Steel in environments with high humidity, saltwater exposure, or industrial pollutants.

2. Strength and Durability

Stainless Steel’s composition makes it inherently stronger and more durable than galvanized steel. Different grades of Stainless Steel offer varying levels of strength:

- 410 Stainless Steel: Known for hardness and wear resistance, used in cutlery and fasteners.

- 430 Stainless Steel: A lower-cost option with good corrosion resistance but less strength.

Galvanized steel, while durable for its cost, relies on its zinc coating for protection. Over time, exposure to extreme weather or heavy loads may compromise its structural integrity.

Verdict: Stainless steel is superior for applications requiring high strength and durability.

3. Cost

Galvanized steel is significantly cheaper than stainless steel, both in terms of initial material cost and production. This affordability makes it an attractive option for large-scale projects where budget constraints are a factor, such as roofing, fencing, or agricultural equipment.

However, stainless steel may offer better long-term value due to its durability and minimal maintenance requirements.

Verdict: Galvanized steel is the economical choice for short- to medium-term use, while stainless steel is better for projects requiring longevity.

4. Maintenance and Longevity

Stainless steel is virtually maintenance-free. Its corrosion resistance ensures a long lifespan, even in harsh environments. For example 17-4 Stainless Steel used in aerospace and chemical processing due to its high strength and corrosion resistance over decades.

Galvanized steel requires periodic inspections to ensure the zinc coating remains intact. In corrosive environments, the coating may need to be reapplied or the steel replaced altogether.

Verdict: Stainless steel requires less maintenance and lasts longer, especially in aggressive environments.

5. Appearance

Stainless steel has a polished, modern appearance that is aesthetically pleasing for visible applications, such as countertops, kitchen appliances, or architectural metal works. In comparison, galvanized steel has a dull, spangled finish that is less visually appealing.

Verdict: Stainless steel wins for aesthetics.

6. Environmental Impact

Both materials are recyclable, but their production processes differ:

- Galvanized Steel: The zinc coating can pose environmental concerns if not managed properly.

- Stainless Steel: Although more energy-intensive to produce, its long lifespan and recyclability make it an environmentally responsible choice.

Verdict: Both materials are environmentally friendly when managed responsibly.

Common Applications of Galvanized Steel and Stainless Steel

Applications of Galvanized Steel

Galvanized steel is widely used across various industries due to its durability and cost-effectiveness.

In the construction sector, it is commonly employed for roofing, structural beams, and fencing, where its zinc coating provides resistance to rust and ensures longevity in outdoor environments.

In the automotive industry, galvanized steel is a preferred choice for frames and underbody components, offering protection against corrosion caused by road salt and moisture.

Similarly, in agriculture, it is used for irrigation systems and storage silos, where it withstands exposure to weather and moisture, ensuring long-term reliability.

Applications of Stainless Steel

Stainless steel, known for its exceptional corrosion resistance and strength, finds extensive use in specialized applications.

In the food and beverage industry, 18/10 stainless steel is widely used in cookware, cutlery, and industrial kitchens due to its resistance to staining, rust, and high temperatures.

In marine environments, 316 stainless steel is the material of choice for boat fittings, docks, and other applications exposed to saltwater, thanks to its enhanced corrosion resistance provided by molybdenum.

For medical and aerospace applications, grades like 17-4 stainless steel are used to manufacture surgical instruments, aerospace components, and other precision tools that demand high strength, corrosion resistance, and durability under extreme conditions.

When to Choose Galvanized Steel vs Stainless Steel

Criteria | Galvanized Steel | Stainless Steel |

Budget | Ideal for projects with strict budget constraints. | Suitable when budget allows for higher upfront costs. |

Environment | Best for mild environments with minimal exposure to corrosive elements. | Preferred for environments with high humidity, saltwater, or chemicals. |

Longevity | Suitable for temporary or short-term solutions. | Ideal for projects requiring durability and long-term reliability. |

Aesthetics | Functional but lacks polished or sleek appearance. | Offers a sleek, polished finish suitable for visible applications. |

Corrosion Resistance | Provides basic corrosion resistance through zinc coating. | Delivers superior, intrinsic corrosion resistance. |

This matrix clearly defines the suitability of each material for specific application.

Conclusion

The debate between galvanized steel vs stainless steel boils down to balancing cost, performance, and environmental factors. While galvanized steel is a budget-friendly option for mild environments, stainless steel offers unmatched corrosion resistance, durability, and aesthetic appeal. By understanding the properties of materials like 304 stainless steel, 316 stainless steel, or 440 stainless steel, you can make informed decisions tailored to your specific needs. Whether you’re constructing a bridge, outfitting a kitchen, or building marine equipment, the right choice ensures longevity, performance, and value for your investment.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant Quote!