In-Depth Understanding of Weld-On Spring Latches for Secure Closures

Gain insights into the engineering and applications of weld-on spring latches, essential for robust closures in diverse settings. This guide elaborates on their components, benefits, and installation techniques, highlighting their critical role in secure closures.

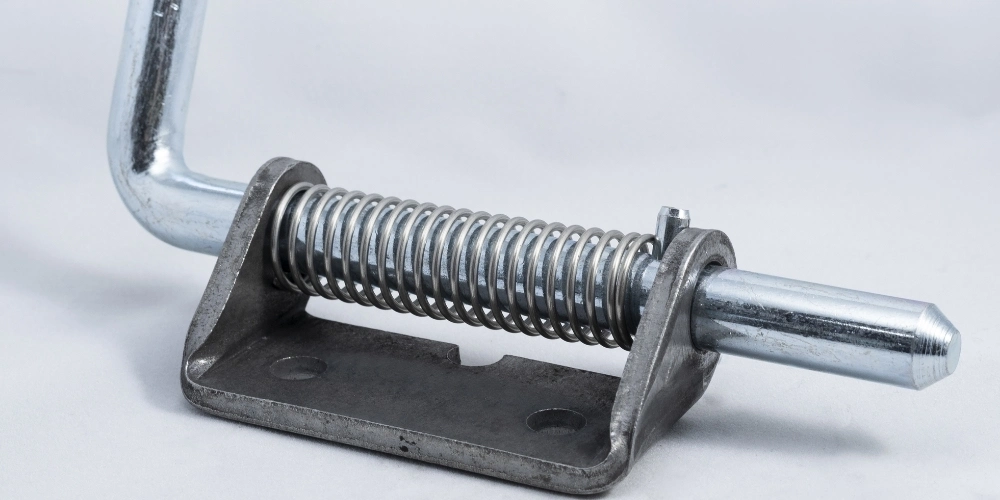

Understanding Weld-On Spring Latch

A weld-on spring latch manifests as a variety of latch mechanism deployed across diverse applications, be it doors, gates, or panels, necessitating a steadfast closure. This latch undergoes meticulous design to undergo direct welding onto the surface of a structure, thus birthing a robust and enduring attachment.

Components of a Spring Latch

- Engagement Mechanism: Comprising a fastener and striker, this vital locking structure ensures secure closure by meticulously connecting to the door or gate upon closing.

- Elastic Tensioning Design: The latch’s operational efficiency is driven by an elastic component inducing autonomous engagement when the door is sealed, eliminating the need for manual intervention.

- Weld-On Configuration: The “weld-on” designation indicates intentional design for direct welding onto the structure’s surface, creating a robust and enduring fusion that enhances overall strength and security.

Key Features of a Weld-On Spring Latch

- Weldable Construction: As the nomenclature implies, this genre of latch is purposed for direct fusion onto the facade of a door, gate, or analogous structures. This guarantees a robust and enduring affixation.

- Mechanism of Springs: The latch integrates a mechanism reliant on springs, facilitating an automatic reversion to a sealed position subsequent to its opening. This attribute introduces convenience and assures the secure closure of doors or gates during periods of disuse.

- Liberation of the Latch: Typically, a Weld-On Spring Latch incorporates a mechanism for facile manual release, enabling users to manually unlatch when necessary. This provision enhances adaptability and user governance.

- Versatility in Installation: The inherent weldability of these latches bequeaths adaptability concerning installation. They may be strategically positioned in the most apropos location for optimum functionality and convenience.

The Primary Applications of Weld-On Spring Latch

A Weld-On Spring Latch is predominantly utilized in diverse applications where a robust and permanent closure mechanism is essential. Commonly employed in doors, both residential and commercial, it ensures a secure attachment through welding directly onto the door’s surface. Additionally, it finds application in gates, ranging from garden gates to larger driveway gates, providing a reliable means of closure. This type of latch is also commonly used in cabinets, such as kitchen and office cabinets, ensuring doors are securely closed. Its adaptability extends to fences, both residential and perimeter fencing, as well as storage units, toolboxes, and even in marine settings like boat compartments. The weldable design offers flexibility, making it a go-to choice for installations requiring a sturdy and durable latch.

Materials Used in the Production of a Spring Latch

Spring latches undergo a meticulous crafting process, employing a spectrum of materials to ensure both durability and functionality. Choices encompass stalwart steel tailored for rigorous applications, corrosion-defying stainless steel ideal for open-air or maritime settings, the amalgam of lightweight and resilient aluminum striking a harmonious equilibrium in the strength-to-weight paradigm, zinc conferring augmented resilience to corrosion, high-strength polymers or plastics catering to specialized needs, and the visually pleasing brass. The selection of materials hinges on myriad considerations, including environmental exigencies, load-bearing capabilities, and the quest for an optimal equilibrium between robustness and weight. This meticulous approach renders these latches versatile across a myriad of industries and scenarios.

Finishes Suitable for a Weld-On Spring Latch

- Zinc Plating: Proffers resistance against corrosion and imparts a consistent visage, albeit susceptible to wear over time, particularly in hostile surroundings.

- Galvanized Coating: Bestows exemplary resistance to corrosion, especially in al fresco settings, with potential considerations regarding thickness and their impact on fit.

- Powder Coating: Exudes resilience, corrosion resilience, and a spectrum of color possibilities; nonetheless, the meticulousness in application becomes pivotal to forestall potential chipping.

- Nickel Plating: Endows corrosion resistance and an appealing veneer, although it might exhibit comparatively less tenacity when weighed against alternative coatings.

- Chrome Plating: Harmonizes aesthetic allure with corrosion resilience, albeit prone to an elevated likelihood of chipping.

- Black Oxide Coating: Attires the latch in a somber finish with a degree of corrosion resistance, though its fortitude might dwindle in adverse conditions.

- Painted Finish: Facilitates a myriad of color customization options, albeit potentially offering diminished resistance to corrosion when juxtaposed with alternative finishes.

Choose the Right Weld-On Spring Latch

Navigating the intricacies of weld-on spring latch selection demands contemplation of pivotal elements. Materials and finishes tailored for specific environments, load capacities, latch types, mounting styles, and dimensional considerations form the bedrock. Scrutinize the spring mechanism, latch operation, and security features, aligning them with the application’s demands for tension, user-friendliness, and robust security. Uphold compliance with industry standards, scrutinize the manufacturer’s standing for quality, and factor in budgetary constraints. This meticulous balancing act culminates in the identification of a dependable and efficient weld-on spring latch, attuned to your precise requirements, ensuring enduring durability.

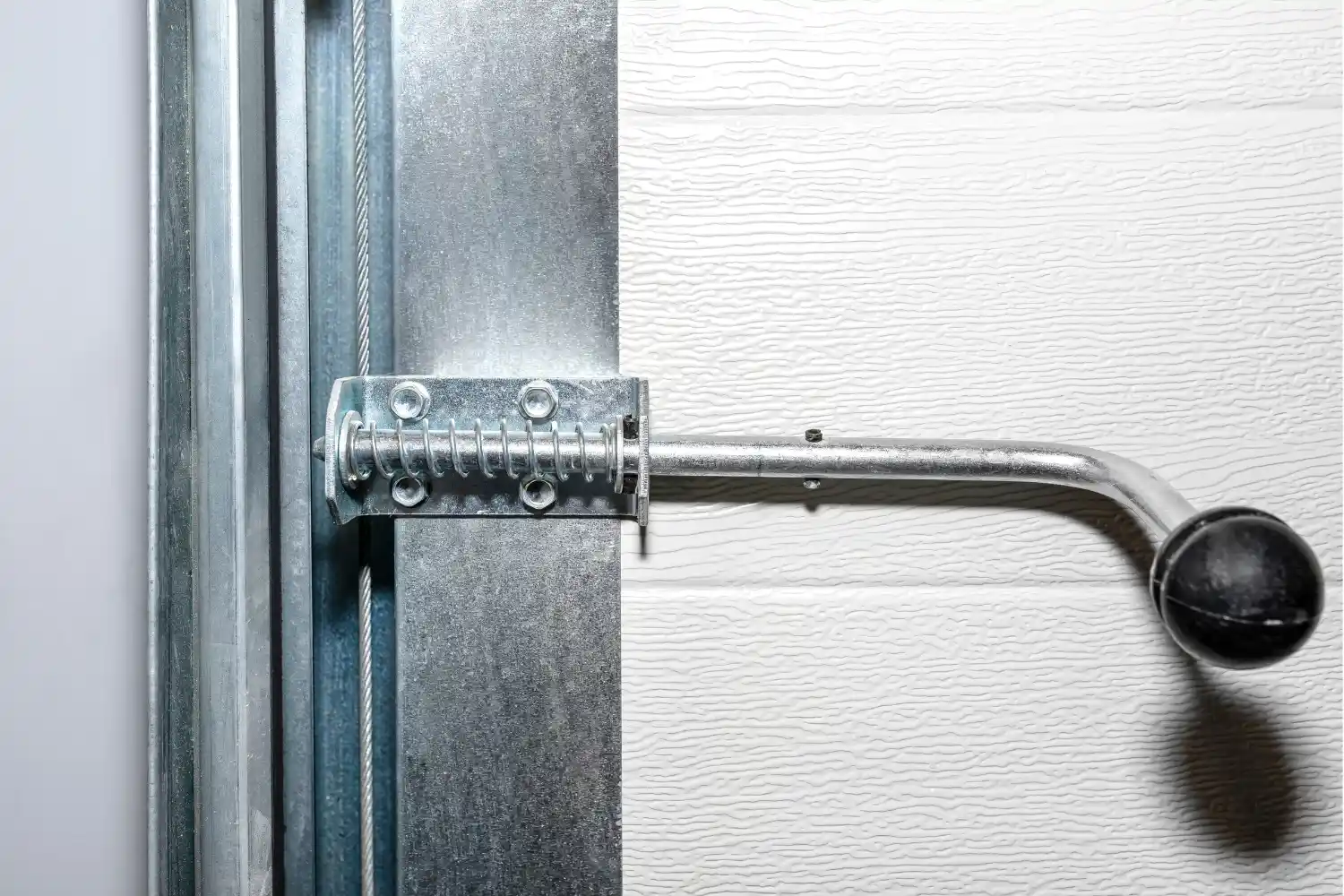

Properly Install a Weld-on Spring Latch

In the meticulous installation of a weld-on spring latch onto a gate or door, commence by discerningly choosing a fitting location that aligns seamlessly with the corresponding strike plate or catch fixed to the stationary frame. Delimitate the mounting orifices, ensuring impeccable alignment. Thoroughly cleanse the surface to guarantee a robust weld. Employ clamps to steadfastly secure the latch in its designated position, scrutinize alignment using a level, and adeptly weld it securely, occupying the mounting holes entirely. Post-welding, refine the region for a polished appearance. Assess the latch’s functionality through rigorous testing, making adjustments if deemed necessary. Optionally, administer a preservative finish to deter corrosion. Scrutinize smooth operation to validate a triumphant installation, consistently prioritizing safety and adhering to meticulous welding methodologies.

Maintain The Spring Latch

To maintain a spring latch effectively, regular cleaning and lubrication are essential to prevent debris accumulation and ensure smooth operation. Periodic inspections for damage, alignment issues, and corrosion, coupled with tightening screws and making necessary adjustments, contribute to the latch’s longevity. Implementing corrosion-resistant finishes for outdoor exposure and installing weather stripping enhance protection. Emphasizing mindful use, prompt replacement of worn parts, and scheduling professional inspections further contribute to the latch’s optimal functionality, promoting reliable security.

Customize Weld-On Spring Latch

- Specify Requirements: Clearly outline size, material, latch type, and special features needed for your application.

- Material Selection: Collaborate on choosing suitable materials based on durability and corrosion resistance.

- Discuss Size and Dimensions: Provide precise measurements for a perfect fit, considering door thickness and mounting space.

- Latch Type and Mechanism: Specify latch type and locking mechanisms, discussing security features if needed.

- Finish and Coating Options: Work together on finishes like zinc plating, galvanized coating, or powder coating for desired aesthetics and functionality.

- Custom Features: Communicate any unique aesthetic preferences or features, such as custom handles or branding.

- Testing Protocols: Discuss and agree upon rigorous testing protocols to ensure quality and adherence to standards.

- Timeline and Production Schedule: Establish a clear timeline and production schedule, including delivery expectations.

- Communication During Production: Maintain open communication for regular updates and issue resolution during the manufacturing process.

- Quality Assurance and Inspection: Emphasize quality assurance and inspection processes for a well-crafted and reliable product

By actively engaging with manufacturers and providing detailed specifications, you can achieve a customized weld-on spring latch that meets your unique requirements. Regular communication and collaboration contribute to a successful partnership between you and the manufacturer.

By actively engaging with manufacturers and providing detailed specifications, you can achieve a customized weld-on spring latch that meets your unique requirements. Regular communication and collaboration contribute to a successful partnership between you and the manufacturer.Conclusion

We trust that this blog has provided valuable insights into the realm of Weld-On Spring Latches. From their fundamental components and features to customization tips and maintenance guidelines, we’ve covered a spectrum of topics to empower your decision-making and usage. Should you have further questions or require additional assistance, feel free to reach out. Thank you for exploring the nuances of weld-on spring latches with us, and may your latch-related endeavors be both secure and seamlessly functional.