Table of Contents

Overview

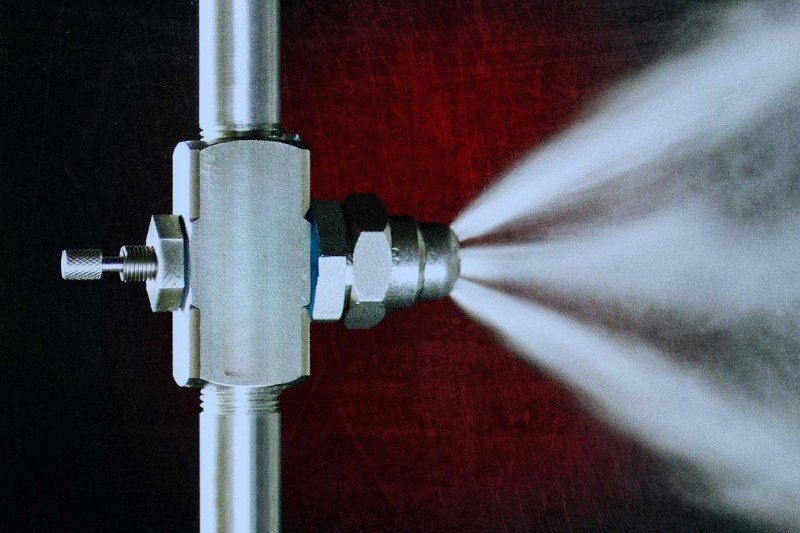

In various industries, CNC machined nozzles control fluids, gases or particles at proper flowrates ensuring excellent precision and accuracy. Such nozzles, customized to a specific application by CNC machining, vary according to the nature of materials that are handled and particular flow control function applied. Different materials are used for making these modular forms to meet certain needs or demands, while several finishing methods being applied further improves its efficiency. As compared to other CNC machining, it has numerous benefits that are being provided like manufacturing nozzles is very efficient along with precision and customization there various advantages in such a manner that the cost will be benefited. The type of CNC machining techniques used vary based on the configuration and nature of materials used in forming the nozzle. Connections to pipelines are variably developed depending on application while the type of use dictates the typr of use and kind of industries.

Get to Know CNC Machined Nozzle

A CNC nozzle in machining is a precisely engineered piece that forms part of many industries and controls the flow of fluids, gases or particles. Built with CNC machining, these nozzles can be formed from various materials like metals and plastics which are used to serve different functions for example spray applications, fuel injection devices and propulsion. An excellent precision level regarding customization especially the variations in diameter, shape flow rate and internal geometries is essential to functional specifications through CNC machining process. These are valued nozzles because of their ability to direct and regulate fluid flow with high precision and trustworthiness.

Applied Industry of Nozzles

Applications of nozzles from different areas are spread across diverse sectors such as manufacturing, automotive, aerospace, chemical industry; food processing & agriculture, pharmaceutical industry; Environmental control system such as FFG- trash sorting and firefighting operations, water treatment plant processes etc . and many more. They act as turrets to regulate both the flow of fluid or gas, having application in activities such as coating, propulsion, chemical dressing upbackslash food production and environmental cleansing. Whatever type may be it in manufacture where coatings are applied or when fuel is being injected into engines of various vehicles and agricultural products chemicals that is pumped out through nozzles, these parts have a very crucial role to play to ensure uniform processes across a wide range of fields.

Types of Nozzles

Based on Material Handled:

- Liquid Nozzles: Designed for handling liquids, including water, chemicals, and various industrial fluids.

- Gas Nozzles: Suited for handling gases, including air, natural gas, and compressed air.

- Multiphase Nozzles: Used for handling mixtures of gases and liquids, often found in the oil and gas industry.

Based on the Flow Control Mechanism:

- Pressure Nozzles: Controlled by fluid pressure to regulate flow and spray pattern.

- Pneumatic Nozzles: Use compressed air for atomization and flow control.

- Hydraulic Nozzles: Operate with hydraulic systems to control fluid flow.

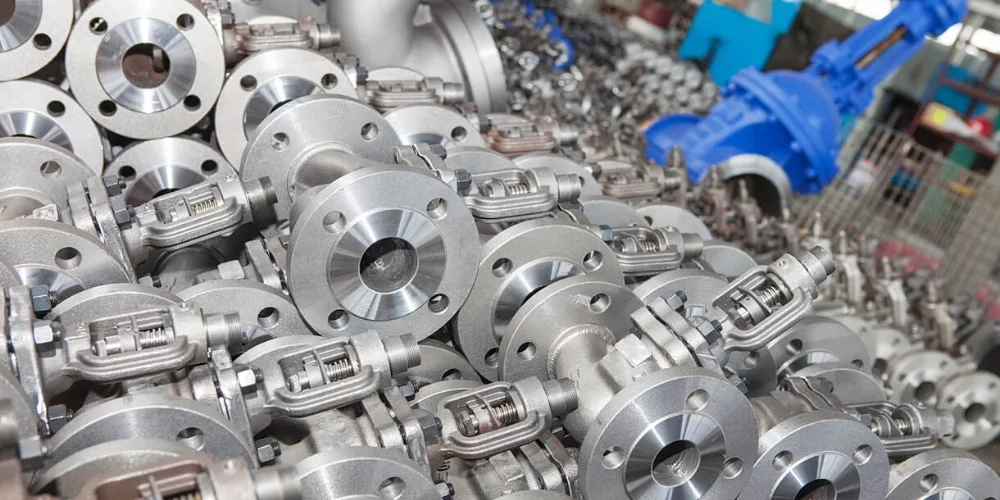

Materials Commonly Used to Make Nozzles

Nozzles are developed out of a number of substances depending on user needs. Examples of these materials are stainless steel for corrosion resistance, aluminum when used in lightweight applications, brass because it has good corrosion resistance, copper for high thermal conductivity and bronzes with wear properties and polymers such as PTFE or polypropylene since they have chemical compatibility. The materials that provide wear resistance are ceramics and hardened steel while tungsten carbide is highly hard. Various factors including the level of abrasiveness, temperature, pressure, and specific types of fluid determine the choice of material; nonetheless, nozzles can perform well in various industries.

Available Finishes for CNC Nozzles

Various coatings and treatments are made available to finish CNC machined nozzles, which make them more efficient and resilient. The finishes that are included in this is polishing the surfaces to create less friction, anodizing because it prevents corrosion especially on aluminum nozzles, electroplating for enhanced appearance performance and wear resistance passivation which ensures stainless steel can’t withstand corrosion Teflon coating owing not stick properties as well as chemical stability hard coats The finishing used is specific for the choice of nozzle material and based on its functional requirements, application environment.

Benefits of Using CNC Machining for Nozzles

The nozzle manufacturing process by CNC machining allows producers to receive several benefits over the traditional one such as precision, high customization level and variety of raw materials. It guarantees tolerances, which enable easy control of fluid flow and excellent performance. The process can use a wide range of materials, the metals and any other available material used with necessary precautions; it features complex nozzle designs that help in getting the best results. One of the advantages of CNC machining is that it is cost-effective in developing large quantities, its quick turnaround time considerably reduces lead by ensuring proper quality control measures. As a whole, it’s an ideal technique for manufacturing a variety of nozzle styles across industries such as the manufacture, aerospace industry, the automotive sector and the chemical processing industry.

CNC Machining Techniques Suitable for Manufacturing Nozzles

Various CNC machining techniques can be used to manufacture nozzles with precision and consistency, such as turning, milling, or electrical discharge machining (EDM). The specific techniques employed will depend on the design and material of the nozzle, as well as the intended application.

The Way Nozzles Connect to Pipelines

Nozzles can be installed through a variety of ways such as threaded, flanged, welded clamp or quick-disconnect, compression fittings, push-to-connect, flare gasketed and bayonet installers. Threaded joints provide strong and tight joint connections that do not leak and flanged are easy to install, assemble or disassemble. Welded connections allow for a secure, long-term seal while clamp and quick disconnect systems permit rapid assembly and disassembly. The fittings ensure leak-free connections such as compression and push-to-connect fittings, while flare fittings are for gas application. Gasketed connections use seals for watertight or airtight connection, and bayonet-connections work via twisting to lock in position. The selection of connection varies with the liquid or gas, sealing requirement, installation ease and maintenance ease.

CNC Machining Suitable for Mass-Producing Nozzles

CNC machining is an excellent choice for mass-producing nozzles due to its automation, precision, consistency, cost-effectiveness, and ability to meet high-quality standards. It ensures that large quantities of high-quality nozzles can be manufactured efficiently, meeting the demands of diverse industries and applications.

Guidance for Customize CNC Nozzles

Customizing CNC nozzles from manufacturers involves a structured process: specify your needs, find and engage suppliers, select material and shape, factor in cooling lubrication or consider compatibility with special settings if required; define what quality assurance you require; estimate cost and lead time for delivery of components to be fitted by you.; determine how much testing will be done on site before commissioning the product , where adjustment can then be made; enquire at this Thus, it requires communication with the company to keep you in line with your final customized CNC nozzle specifications that suit your machining needs.

Conclusion

Conclusively, nozzles machined via CNC have numerous applications across industries; however, their essential purpose is to provide precision control and regulation of fluid flow or gas. The CNC machining customization built into the options offers customer-specific solutions to remedy individual needs, and various materials and finishes improve their functionality. Owing to its reliability, affordability, and the ability of machine cycling the practice has become ideal for mass producing quality nozzles across industries ranging from manufacturing appliance to aerospace automotive among others as wells as chemical processing. It helps if a person has effective communication and collaboration with manufacturers in order to get the ideal customized CNC nozzle regarding his machining needs.

Resources: