Guide to 5 Stainless Steel Types: Properties, Grades & Applications

- By: dong

Different types of stainless steel affect a product’s corrosion resistance, lifespan, and cost. If you’re unsure which type of stainless steel to choose as your preferred material for custom metal products, this blog will help you make the right choice by discussing the properties and applications of common stainless steel types.

5 Types of stainless steel

According to the metallographic structure of stainless steel, we classify stainless steel families into 5 types: Austenitic Stainless Steel, Ferritic Stainless Steel, Martensitic Stainless Steel, Duplex Stainless Steel, and Precipitation-Hardening (PH) Stainless Steel.

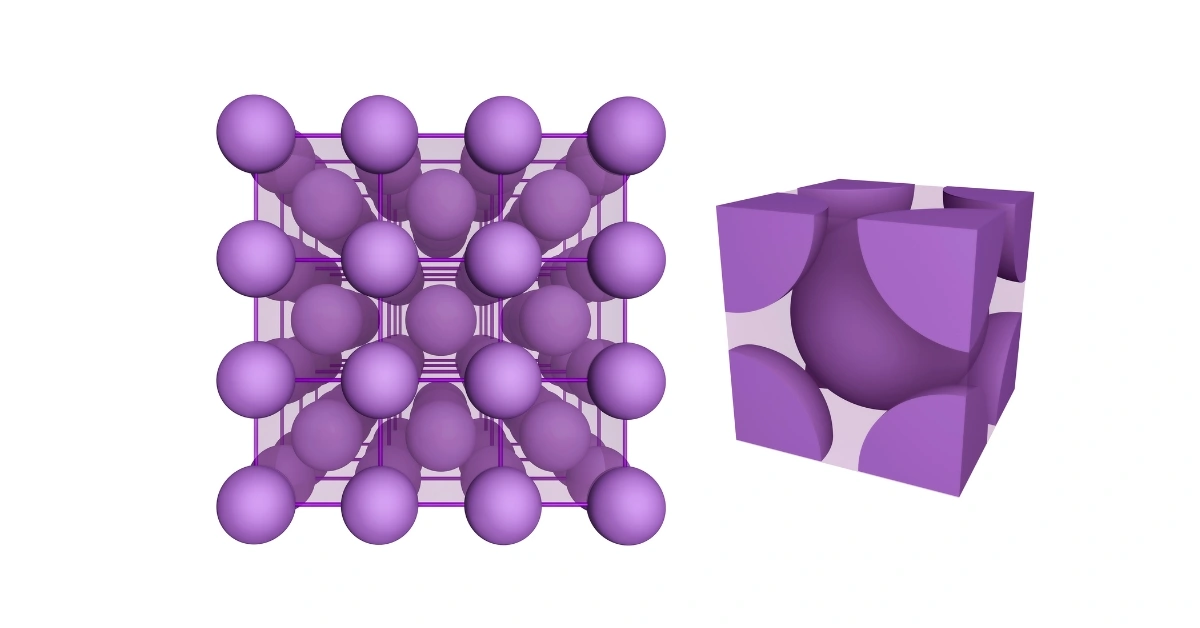

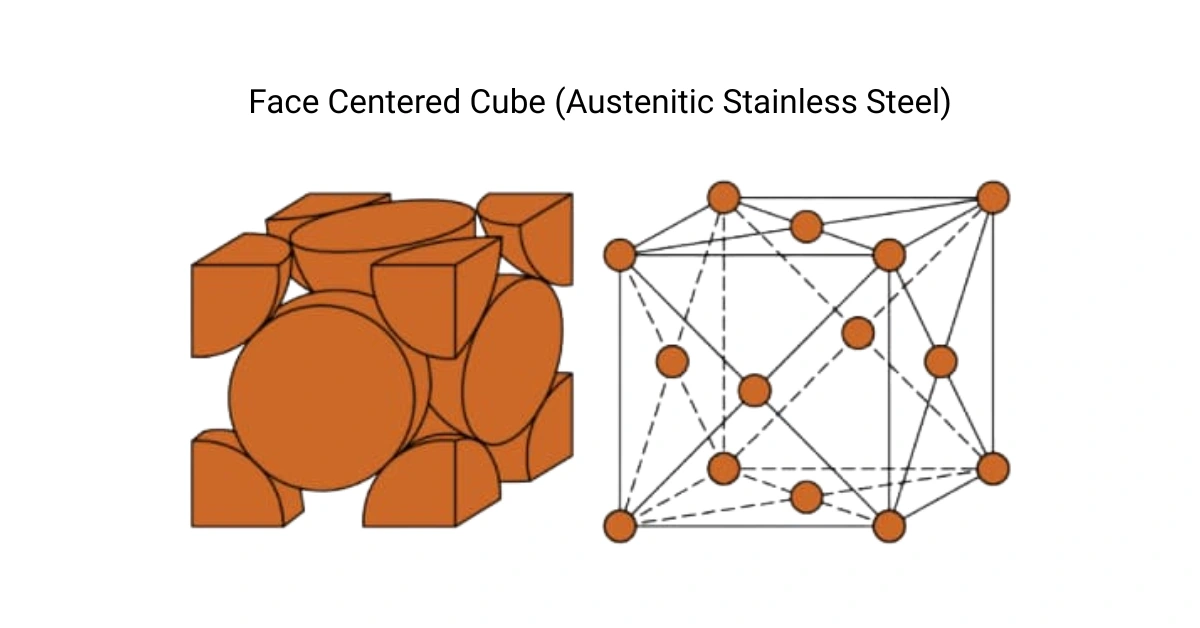

Austenitic Stainless Steel

What it is: Austenitic stainless steel is a type of stainless steel that adds high levels of chromium and nickel to iron-based alloys, and can add alloying elements such as molybdenum and nitrogen, forming and maintaining a face-centered cubic (FCC) structure at room temperature. It is the most widely used classification of stainless steel.

Chemical components: It contains 16-26% chromium(Cr), 6-22% nickel(Ni), less than 0.08% carbon(C), and some grades contain 2-3% molybdenum(Mo), 0.1-0.3% nitrogen(N).

Corrosion resistance: High chromium content ensures the extremely high corrosion resistance of austenitic stainless steel, while the presence of molybdenum enhances its resistance to pitting and intergranular corrosion.

Physical properties:

- High toughness

- High strength and hardness (after cold working)

- Moderate temperature resistance

Magnetic: Usually non-magnetic, it may have weak magnetism after cold working process, such as CNC turning, bending, or stamping.

Machinability: The machinability of austenitic stainless steel is average, but it has excellent weldability.

Application:

- Food processing equipment: pump housing, valve, cabinetry…

- Chemical equipment: chemical storage tank, pump, compressor part…

- Marine industry: seawater pipe system, railing, coastal building structures…

Common grades:

Ferritic Stainless Steel

What it is: Ferritic stainless steel is a type of stainless steel with iron (Fe) as the base, characterized by high chromium(Cr) content and almost no nickel(Ni), maintaining a body-centered cubic (BCC) structure at both room temperature and high temperatures (about 900-950°C).

Chemical components: It contains 10.5-30% chromium, less than 2% or even no nickel, less than 0.08% carbon, and some grades contain molybdenum, titanium, or niobium.

Physical properties:

- Good high-temperature oxidation resistance

- Excellent thermal conductivity

- Poor low-temperature toughness

Corrosion resistance: The chromium content ensures good corrosion resistance in ferritic stainless steels, and some grades with molybdenum have good pitting corrosion resistance. In addition, grades with titanium and niobium elements have strong resistance to intergranular corrosion.

Magnitic: It is magnetic and this property does not change with any processing.

Machinability: It has excellent machinability and weldability.

Applications:

- Automotive: exhaust manifold, fuel tank cap, sensor bracket…

- Household appliance: microwave oven housing, heater housing, decorative trim…

Common grades:

- 430

- 409

- 443

Martensitic Stainless Steel

What it is: Martensitic stainless steel is a type of stainless steel that forms a martensitic structure through quenching and achieves a good balance of strength, hardness and toughness after tempering.

Chemical components: It contains 11-18% chromium, 0.1-1.2% carbon, and some grades have small amounts of nickel, molybdenum, vanadium, and niobium.

Physical properties:

- High strength and hardness

- Good wear resistance and fatigue resistance

Corrosion resistance: The corrosion resistance of martensitic stainless steel is generally moderate.

Machinability: It has good machinability in the annealed state, but the weldability is very poor.

Magnetic: It is magnetic.

Application:

- Mechanical & General engineering: pump shaft, valve body, fastener, bushing…

- Medical devices: surgical scissors and knife, bone screw, replacement joint…

Common grades:

Duplex Stainless Steel

What it is: Duplex stainless steel is a type of stainless steel that forms and maintains a mixed microstructure of austenite (FCC) and ferrite (BCC) at room temperature through solution treatment of alloys with precisely designed chemical compositions.

Chemical components: It contains 19-28% chromium, 4.5-8.5% nickel, up to 5% molybdenum, 0.1-0.3% nitrogen, and less than 0.03% carbon.

Physical properties:

- High tensile strength and yield strength

- Good toughness and ductility

Corrosion resistance: It has excellent corrosion resistance, and strong resistance to pitting and crevice corrosion. Furthermore, it has excellent stress corrosion resistance.

Machinability: It has good machinability but moderate weldability.

Magnetic: It is magnetic.

Applications:

- Oil & Gas: storage tanks, process piping, pressure vessels…

- Petrochemical & Chemical: pump housing, high-pressure absorber…

- Marine Engineering: firefighting system…

Common grades:

- 2304

- 2205

- 2507

- 2707

Precipitation-Hardening (PH) Stainless Steel

What it is: Precipitation-hardening stainless steel is a highly customizable alloy that builds upon the base of stainless steel by adding specific elements such as copper, aluminum, and niobium. It then undergoes targeted heat treatment (solution treatment + aging) to enhance the material’s mechanical properties, primarily yield strength, tensile strength, and hardness.

Chemical components: PH stainless steel contains 15-17% chromium, 3-8% nickel, trace amounts of carbon, and typical precipitating elements such as copper, aluminum, and niobium.

Physical properties:

- High strength and hardness

- Dimensional stability

- High toughness

- Good wear resistance

Corrosion resistance: Sufficient chromium content and minimal carbon content give it good corrosion resistance.

Magnetic: Typically magnetic.

Machinability: It has good machinability and can be processed in its solid solution state, followed by aging strengthening treatment to obtain high-precision products.

Application:

- Aerospace components: turbine blade, engine fastener…

- Turbines

Common grades:

- 17-4

- 15-5

- 17-7

Comparison of Common Grades of Stainless Steel

To allow you to better understand the advantages and disadvantages, application scenarios, and cost-effectiveness of materials, we will conduct an in-depth comparison of some commonly used different grades of stainless steel, hoping to provide a better decision-making basis for your customized projects:

SUS304 vs SUS316

304 and 316 are the two most common levels of stainless steel in the austenitic stainless steel family, so their corrosion resistance is self-evident.

However, 316 contains 2-3% molybdenum—something 304 lacks. The presence of Mo enhances 316’s resistance to pitting and crevice corrosion. Therefore, in environments with high chloride ion (Cl⁻)content, such as chemical or marine environments, the advantages of 316 are more pronounced.

If your custom projects are cost-sensitive and don’t require extreme corrosion resistance, such as for food-grade products or industrial equipment, then 304 is the most suitable level.

If your products need to be exposed to seawater or chemical substances for extended periods, then 316 will provide you with excellent value for money.

304 vs 430

304 contains 8-10.5% nickel, while 430 does not contain nickel, which is the main reason for the corrosion resistance and price difference between the two stainless steels. Although the corrosion resistance of 430 is not as good as that of 304, it is a cost-effective choice for use in dry, mild, and indoor environments. In addition, 430, as a ferritic stainless steel, is magnetic, while 304 is non-magnetic in the general state.

If your product prioritizes cost and is only used in a dry indoor environment, then the 430 fits the bill.

316 vs 316L

Both being austenitic stainless steels, 316L is the low-carbon version of 316. The carbon content in 316 is less than 0.08%, while in 316L it is less than 0.03%.

The carbon content affects the welding performance of stainless steel, and 316L has a lower risk of intergranular corrosion after welding compared to 316.

Therefore, if your product requires extensive welding and does not demand extremely high strength, 316L is more suitable for your needs. Conversely, 316 is more appropriate.

Which Kinds of Stainless Steel are Suitable for Processing?

Different stainless steels have their own suitable processing methods. Some ratings are more suitable for investment casting, some can maximize their advantages after hot forging, and others are better suited for CNC machining.

We will help you choose the right stainless steel material according to your customized metal product project, and provide the best processing and surface treatment solutions.

Processing methods | Stainless Steel | Advantages |

Austenitic Stainless Steel(304/304L/316/316L)/Duplex Stainless Steel | Investment casting can produce stainless steel parts with complex structures and unique shapes. We offer precision casting services, which involve CNC machining after casting to improve the precision. | |

Austenitic Stainless Steel/Martensitic Stainless Steel/Duplex Stainless Steel | Hot-forged stainless steel products have a dense internal structure, high strength, and strong load-bearing capacity, making them fit for producing load-bearing components, like flanges, mountings, and pipe fittings. | |

Austenitic Stainless Steel(304/316/316L) /Martensitic Stainless Steel(410/420) /Ferritic Stainless Steel(430)/PH Stainless Steel | We can adjust the milling and turning parameters according to the type and characteristics of stainless steel to meet requirements for dimensions, precision, and surface finish. This is especially advantageous in small- to medium-batch custom projects. | |

Austenitic Stainless Steel(304/304L/316/316L) | We can provide laser cutting, bending, stamping, and especially welding service, and can combine these with CNC machining to complete structural components. |

Comparison of Common Stainless Steel Grades’ Major Standards

The same stainless steel has different grades under different standard systems. The table below shows you the corresponding grades of common stainless steels in your country or internationally, which can help you communicate more smoothly when making decisions.

Commercial Name | U.S. | Europe/INTL | Japan | China |

AISI/ASTM | UNS | EN(Number) | JIS | |

304 | 304 | S30400 | 1.4301 | SUS 304 |

304L | 304L | S30403 | 1.4307/1.4306 | SUS 304L |

316 | 316 | S31600 | 1.4401 | SUS 316 |

316L | 316L | S31603 | 1.4404 | SUS 316L |

430 | 430 | S43000 | 1.4016 | SUS 430 |

443 | – | S43300 | 1.4512 | SUS 443 |

410 | 410 | S41000 | 1.4006 | SUS 410 |

440C | 440C | S44004 | 1.4125 | SUS 440C |

2205 | S32205 | S32205 | 1.4462 | SUS 329J3L |

2507 | S32750 | S32750 | 1.4410 | – |

17-4PH | 630 | S17400 | 1.4542 | SUS 630 |

How to Choose the Right Type of Stainless Steel for Your Custom Metal Parts

For your custom project, you need to consider multiple levels to find the best specific type from stainless steel families.

- Usage environment: If your product is primarily used indoors, in a dry, mild environment, then materials with moderate corrosion resistance, such as 430 or 409, are sufficient. However, if your product needs to withstand humid, chemical, or marine environments, you need to focus on stainless steels with strong corrosion resistance, such as 316 or 2205.

- Mechanical performance requirements: If your product requires long-term repeated use, then the stainless steel material you choose needs to meet the advantages of high strength and wear resistance, such as 410, 17-4PH.

- Manufacturing process: For products with high requirements on dimensions and tolerance precision, stainless steel suitable for CNC machining should be selected. If your product requires excellent density and strength, stainless steels match for hot forging processing can better realize its value. If the product has a complex structure and a unique shape, then stainless steel suitable for investment casting should be considered.

- Surface and appearance requirements: Different surface treatments also affect the functionality and aesthetics of stainless steel products. For example, heat treatment can additionally increase the hardness of martensitic stainless steel; mirror polishing, brushing, sandblasting, and PVD coating can enhance the appearance of austenitic stainless steel, among other effects.

- Industry standard requirements: Specific industries also require stainless steel products to meet industry standards, for example, when it comes to food and medical aspects, you have to choose food-grade stainless steel, medical-grade stainless steel, etc.

- Cost: If your team is sensitive to the cost of the product, most ferritic stainless steels offer you a balance of cost and performance.

Choose HDC, and we will recommend suitable stainless steel materials for you with professional experience, provide the most appropriate and efficient production methods and surface treatment options, reducing your costs, waiting time, and communication barriers.

FAQ

1. What are the main types of stainless steel?

There are five types of stainless steel, including austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, duplex stainless steel, and PH stainless steel.

2. Which stainless steel is best for chemical or marine environments?

Austenitic stainless steel, especially 316 and duplex stainless steel.

3. What surface treatments can be performed on stainless steel?

Polishing, pickling, passivation, electropolishing, PVD coating, brushing, and more.

4. Can stainless steel be anodized?

Stainless steel cannot be anodized, only aluminum can be anodized.

5. What is the cheapest stainless steel?

Ferritic stainless steel, like 430, 439, because their chemical composition does not contain the precious metal nickel and their manufacturing process is very simple.

6. What types of stainless steel can you provide?

We can supply a variety of stainless steels for custom processing, such as 304, 304L, 316, 316L, 17-4, 2205, 410, 430…

7. Do you supply material certificates/traceability?

Yes. We can provide material certificates and traceability after order confirmation, as they are issued per production batch.

Conclusion

We hope this blog will provide crucial assistance in your product material selection.

HDC provides custom stainless steel processing services, including precision casting, hot forging, CNC machining, and sheet metal fabrication services, as well as surface treatment services.

If you are looking for a reliable supplier for your custom metal product projects, we can provide a one-stop service from production to shipping. Please feel free to contact us for a quote.

What are the main types of stainless steel?

There are five types of stainless steel, including austenitic stainless steel, martensitic stainless steel, ferritic stainless steel, duplex stainless steel, and PH stainless steel.

Which stainless steel is best for chemical or marine environments?

Austenitic stainless steel, especially 316 and duplex stainless steel.

What surface treatments can be performed on stainless steel?

Polishing, pickling, passivation, electropolishing, PVD coating, brushing, and more.

Can stainless steel be anodized?

Stainless steel cannot be anodized, only aluminum can be anodized.

What is the cheapest stainless steel?

Ferritic stainless steel, like 430, 439, because their chemical composition does not contain the precious metal nickel and their manufacturing process is very simple.

What types of stainless steel can you provide?

We can supply a variety of stainless steels for custom processing, such as 304, 304L, 316, 316L, 17-4, 2205, 410, 430…

Do you supply material certificates/traceability?

Yes. We can provide material certificates and traceability after order confirmation, as they are issued per production batch.

Discover more with our blog posts.

Recent Posts

Discover more about our products

HDC Products

Instant free quote!