Closed Die Forging vs. Open Die Forging

Closed Die forging vs. Open Die forging are metal forging processes. Find out what they

With our advanced forging facility and experienced team, we provide application-specified, tailored forging solutions for customers worldwide.

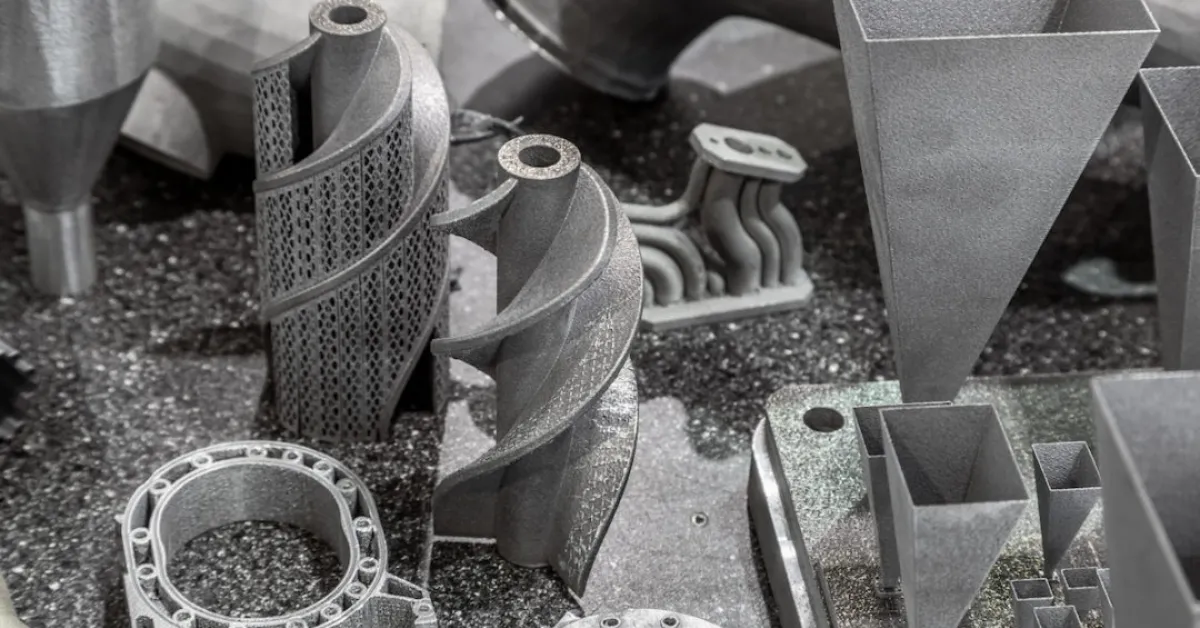

Comprehensive forging service for different project needs

Forging with precision machined dies brings steel forgings with exceptional high quality.

An ideal manufacturing process to produce parts with cylindrical character, such as shafts, axles.

Precision post processing by CNC machining for tight tolerance and higher surface quality.

Comprehensive range of steel grades and post-processing to meet your exact specifications

Quenching and ageing for better strength and toughness

Removing scale and roughening surfaces for cleaning and texture

Dissolving oxides and contaminants chemically for clean surfaces

Achieving precise dimensions and smooth surfaces through machining

Enhancing smoothness and shine for appearance

Bothered by sourcing reliable custom steel forgings? Everyone has their area of expertise. You may be a product expert, but we are experts in the field of forging, providing solutions specifically designed for your project.

Steel forgings are favored by the global industry for their cost-effectiveness and exceptional performance

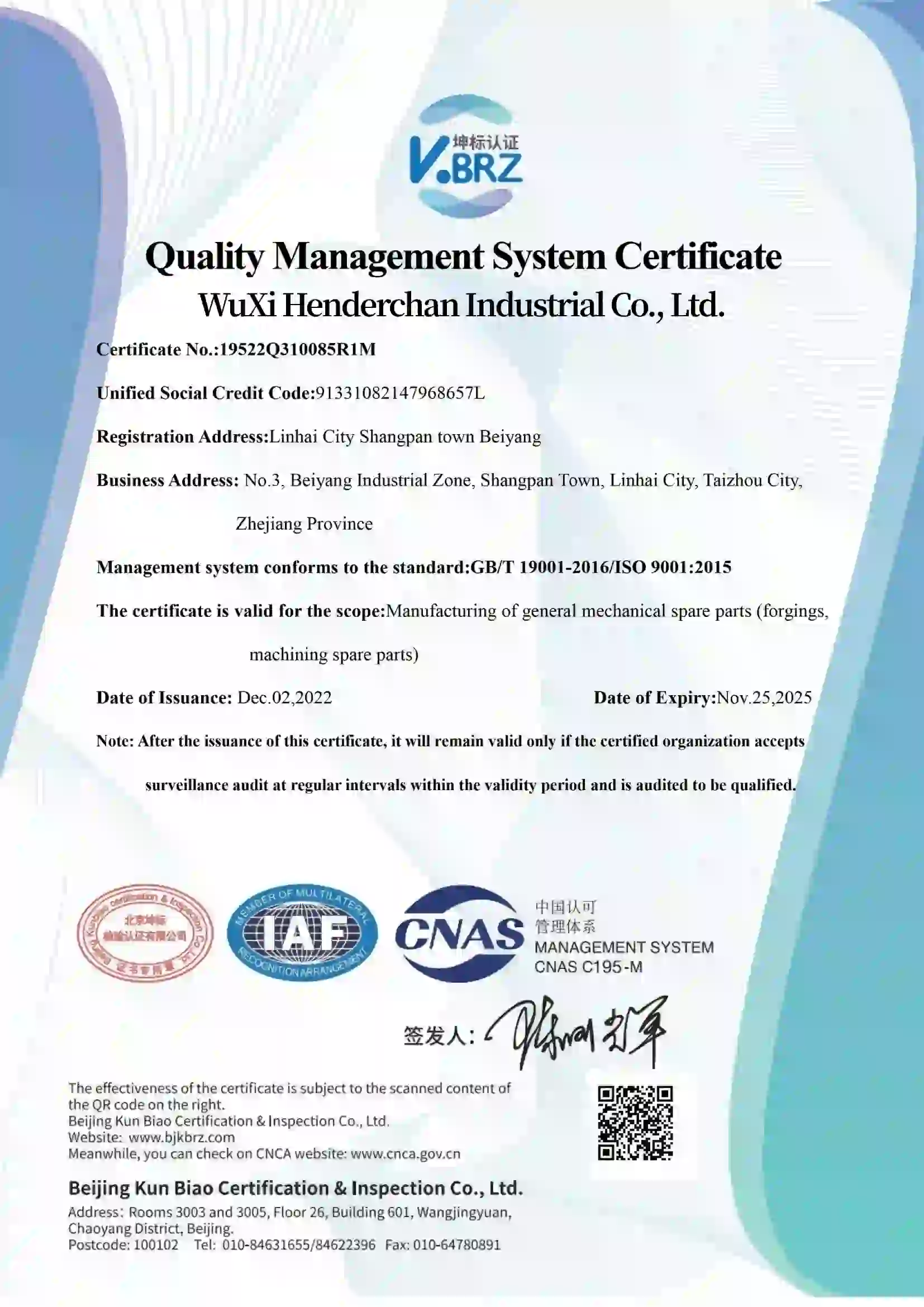

At HDC, quality isn’t just checked – it’s forged into every stage of our manufacturing process. Our commitment to excellence is backed by internationally recognized certifications and a comprehensive suite of advanced inspection technologies.

Verifies the chemical composition of raw materials by a spectrometer

Test yield strength, tensile strength, and hardness to ensure design performance

Measures critical dimensions and surface roughness to ensure functional fit

Non-destructive FPI testing (NDT) to detect microscopic surface defects

Over 10 years of casting excellence delivering superior components worldwide

We handle global logistics, customs & documentation – you receive finished parts seamlessly, anywhere. No export/import expertise needed.

Our engineers transform your concepts into manufacturable designs. Don’t have CAD? Share sketches or samples – we bridge the design gap.

All processes under one roof – from forging (34+ presses, 160T-4000T) to heat/surface treatment, precision machining (40+ CNC centers), and strict quality control (CMM, FPI, material testing).

Multilingual project managers provide clear, responsive updates – no lost-in-translation risks.

ISO/IATF certified with micron-level validation (±0.01mm CMM) of material, dimensions, and defect-free surfaces.

50+ forming machines & 40+ CNC centers ensure on-time delivery – even for complex high-volume orders.

Learn more about HDC through the comprehensive equipment list and the picture gallery of our facility

| Equipment | Quantity | |

|---|---|---|

| Forging | Electric screw press (160T-4000T) | 22 |

| Forging Press (160T-1000T) | 12 | |

| Punch Press | 50 | |

| Roll Forging | 1 | |

| Heat Treatment and Surface Treatment | Quenching Furnace | 1 |

| Ageing Furnace | 2 | |

| Pickling Line | 2 | |

| Polishing Line | 2 | |

| Sandblasting Line | 3 | |

| Machining | Three-Axis Machining Center | 20 |

| Four-Axis Machining Center | 23 | |

| Drilling and Milling Center | 6 | |

| Drilling Machine | 26 | |

| Honing Machine | 2 | |

| Ultrasonic Cleaning | 2 | |

| Broaching Machine | 1 | |

| Testing Equipment | Coordinate Measuring Machine (CMM) | 1 |

| Spectrometer | 1 | |

| Material Tensile Testing Machine | 2 | |

| Hardness Tester | 4 | |

| Profilometer | 1 | |

| Fluorescent Penetrant Inspection Line | 1 |

Steel is the most used metal in the world. This metal family comprises over 1,000 grades of steel and can be found in a wide range of applications, from cookware to vehicles. It’s widespread not only benefits of its huge reserves, but also because it’s easy to process.

Among all these manufacturing methods, forging is a remarkable process that contributes to the development of the steel industry. Let’s break down the advantages of steel forging and get a further understanding before requesting a steel forgings quote.

Find answers to common questions about our steel forging services

Our MOQ varies according to the type of product and the level of complexity:

For R&D projects and small batch production, we offer special solutions, welcome to contact our sales team for consultation.

The standard production cycle is as follows:

We provide comprehensive material certification services, including material test reports( Chemical composition analysis, mechanical property testing), and industry standard certifications.

We promise to solve quality problems 100%. For quality problems caused by production processes or materials, we provide rework, replacement or refund solutions.

We offer flexible payment options:

(30% deposit, 70% paid before shipment)

Yes, we offer sample service:

We recommend you confirm samples before mass production to ensure that the products fully meet the requirements.

Ready to discuss your steel forging project? Our team is ready to assist.

Closed Die forging vs. Open Die forging are metal forging processes. Find out what they

Discover the differences between metal 3D printing, forging, and investment casting. Learn about the strengths,

Choosing between investment casting and forging depends on your specific project requirements. Consulting experts can

The following lists the top ten aluminum alloy forging enterprises in China, in no particular

Forging aluminum is a major component of modern manufacturing industry that has an abundance of