Austenitic Stainless Steels: In-depth Guide

- Von: HDCMFG

Austenitic Stainless Steel Quick-View

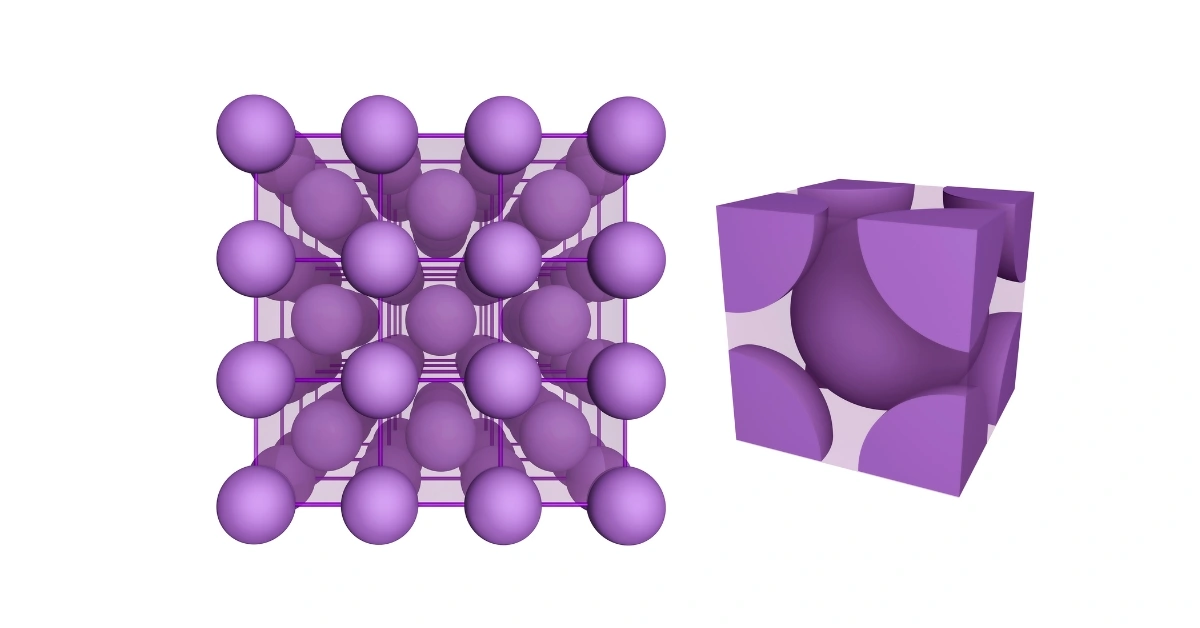

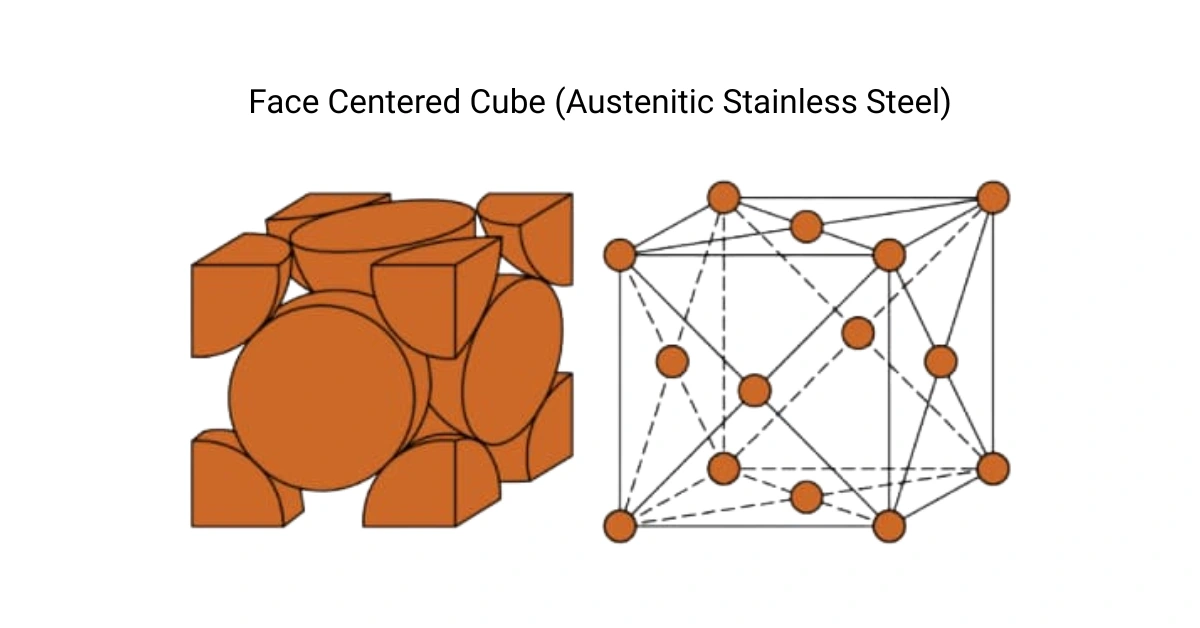

- Was es ist: Chromium–nickel stainless steels with an FCC crystal structure; non-magnetic when annealed

- Main elements: Cr (16–26%), Ni (6–22%), low carbon; optional Mo, N, Ti, Nb

- Key properties: Excellent corrosion resistance, high ductility, good weldability

- Temperature performance: Tough at cryogenic temperatures; good high-temperature strength (grade-dependent)

- Übliche Noten: 304, 316, 303, 321, 347, 310, 904L

- Typical uses: Chemical processing, medical devices, food equipment, power generation, architecture

- Main advantages: Balanced performance, hygienic surface, wide grade availability

- Key limitations: Higher cost, no heat-treatment hardening, chloride SCC risk

✅ Technischer Inhalt von HDC-Ingenieuren geprüft

As a metallurgist or mechanical engineer, you need to have the proper understanding of the benefits and limitations of austentic stainless steels before choosing them for your applications. Choosing these steels without having the right knowledge can lead to higher costs of materials choices that do not fit the needs of your applications. In this article, we’ll walk you through how to solve these problems by explaining what austenitic stainless steels are, their uses, and their unique properties.

What Is Austenitic Stainless Steel?

Austenitic stainless steel is among the most popular types of stainless steels, alongside ferritic, martensitic, and duplex classifications. These steels are composed of several materials, including iron, chromium, nickel, manganese, and carbon. You’ll find austenitic stainless steel in different grades; meanwhile, the most popular are 304 and 316. These steels’ unique properties make them exhibit an excellent structure–face-centered cubic (FCC) crystalline lattice. Primarily, austenitic stainless steels are made up of iron and chromium, but the structure also makes them non-magnetic.

History Of Austenitic Stainless Steel

In 1913, an English metallurgist, Harry Brearley, was the one who took credit for the discovery of stainless steel. At the time, he was deriving means of making steel more erosion resilient while he was working for Firth Brown Laboratories in Sheffield, England. In the process of carrying out various experiments with various compositions, he realised that steels with about 12.8% chromium have high rust and stain resistance. This was how stainless steel became popular over time.

Austenitic Stainless Steel Composition

Primarily, austenitic stainless constituent Iron (Fe), which is usually enhanced with high proportions of key elements. These steels’ chromium content, which is the primary alloying agent, is between 16% and 26%. Nickel is also an important alloying agent, ranging between 6% to 22%. Between 2% to 10% of manganese is usually added. It also has low carbon content, usually below 0.08%. You may decide to add molybdenum, nitrogen, silicon, phosphorus, and sulfur in smaller quantities, depending on what you want to achieve.

How Austenitic Stainless Steel Is Made?

There are many processes involved when you want to make austenitic stainless steel. Your preferred manufacturing process is based on the type of austenitic stainless steel you want to produce and the equipment you’re using as the manufacturer.

- Melting and Refining: This process entails melting down iron with chromium, nickel, and other elements in a furnace. The refining process helps remove impurities and adjust the composition to get the required corrosion resistance, strength, and uniform chemical properties.

- Fortlaufendes Casting: This process entails pouring the molten austenitic stainless steel into a cooled mold and solidifying it into slabs or billets. This process helps improve the uniformity of the materials, reduces waste, saves energy, and makes the steels ready for further shaping operations.

- Warmwalzen: Here, high temperature, usually above its recrystallization point to shape the cast steel. This process reduces thickness, refines grain structure, improve mechanical properties. Plus, with this process, you can easily form the steel into plates, sheets, or coils.

- Kaltwalzen: This process is usually done at room temperature after hot rolling. Kaltwalzen reduces thickness, improves surface finish, increases strength through work hardening, and provides the precise dimensional accuracy required for high-quality austenitic stainless steel products.

Characteristics of Austenitic Stainless Steel?

Austenitic stainless steel exhibits distinct characteristics such as:

- Highly resistant to corrosion in acidic, alkaline, and chloride-laden environments.

- Non-magnetic properties when annealed.

- They’re highly formable with various metalworking processes.

- Good cryogenic behaviour, making it retain its toughness and ductility at very low temperatures.

- Some grades come with good high-temperature strength, making them maintain good mechanical properties, like strength and creep resistance at high temperature.

- The hygienic and rejection of contaminants is due to their smooth, non-porous, and unreactive surface, which makes them easy for you to clean and maintain.

- Low carbon content of austenitic stainless steels, such as 304L and 316L grades have good weldability, thus making them display low sensitization (carbide formation at grain boundaries).

- Austenitic stainless steels are highly recyclable without any loss of properties.

Properties Of Austenitic Stainless Steel

All types of austenitic stainless steels are categorized under the 200 and 300 series. The 300 stainless steel series is the grade with the highest nickel content (plus 904L as a series outlier). They generally have the following properties:

- Nicht magnetisch.

- Hervorragende Korrosionsbeständigkeit.

- Easily weldable.

- High strength at elevated temperature.

- Improved machinability.

Physical Properties of Austenitic Stainless Steel?

Generally, all grades of austenitic stainless steels exhibit a useful range of properties. Some of these properties include:

- They are generally weldable by all normal processes, with some alloys suffering lower carbide sensitization.

- When in their annealed state, the exhibits excellent formability, fabrication capacity, and ductility.

- Comes with great hygiene characteristics and resistance to contamination/staining.

- Retains their properties at high temperatures, and they sometimes have outstanding cryo temperature performance.

- Non-magnetic in their annealed state.

- Hardenable by cold-work only, with some magnetic response in the work-hardened state.

Chemical Properties of Austenitic Stainless Steel?

The list below shows some attractive chemical properties of austenitic stainless steel:

- Face-centered cubic microstructure.

- Inertness, or lack of chemical interaction, with a wide range of environments.

- Universally high corrosion resistance to pH-neutral, mildly acidic/alkaline, and wet environments.

- Some grades feature extreme corrosion resistance for highly acidic/alkaline and high chloride environments.

- The tendency in some alloys to carbide formation at crystal boundaries weakens corrosion resilience. This is resisted by the addition of stabilizing metals that resist this chemical process.

Types of Austenitic Stainless Steel Grades?

The list below shows the various types of austenitic stainless steel grades with various properties.

Edelstahl 304

They are also called “18-8” stainless steel due to their main alloying constituents being 18% chromium and 8% nickel. Not only do 304 stainless steels contain chromium and nickel, but they also have up to 2% maximum manganese, and small amounts of carbon, silicon, phosphorus, and sulfur. You can use 304 stainless steel for industrial products like storage tanks, worktops, sinks, cookware, tanks, piping, surgical instruments, and implant materials.

Edelstahl 316

They are composed of between 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. These properties make this stainless steel good for chloride-rich environments like marine and swimming pool equipment. When temperatures are low, stainless steel 316 retains its ductility and toughness. You can use them in applications such as marine hardware, boat fittings, offshore structures, reactors, etc.

Edelstahl 303

These stainless steels are free-machining steels. They have between 0.15–0.35% sulfur. 303 stainless steel is not only composed of Surfur, but the alloy composition includes between 17–19% chromium, 8–10% nickel, 1% silicon, and small amounts of carbon, manganese, and phosphorus. You can use 303 stainless steel in applications like screw machining, shafts and pins, valve and pump components, bushings and bearings, and other applications where machinability is paramount.

321 Edelstahl

These grades of stainless steels consists between 0.4–0.7% titanium. The inclusion of extra titanium gives it improved weldability, resistance to sensitization, and intergranular corrosion at high temperatures. You can weld them with popular welding methods like TIG or MIG welding. You can use 321 stainless steel for components in aircraft exhaust systems, jet engine parts, afterburners, heat exchangers, exhaust systems, pipes, fittings, and other applications where high-temperature resistance and corrosion resistance cannot be compromised.

310 Edelstahl

These grades of austenitic stainless steel are specially made for high-temperature applications. They consist of 24–26% high proportion of chromium and 19–22% nickel. You can easily weld them compared to other types of austenitic stainless steels due to their large immune sensitization. You can use these steels for applications that involve exposure to intermittent or continuous high-temperature environments and an elevated risk of oxidation. Some include furnace components, trays, baskets, radiant tubes in heat-treating furnaces, tubes, pipes, and vessels in hot processes in chemical plants.

904L Edelstahl

These grades of stainless steel are perfect for aggressive environments like sulfuric acid, chlorides, and other corrosive environments. They come with 19–23%chromium, 23–28% nickel, and 4–5% molybdenum. You can use 904L stainless steel for applications for equipment, pipes, and storage tanks exposed to corrosive chemicals and acids, offshore platforms, heat exchangers, and pipes that come into contact with seawater and corrosive environments, etc.

347 Edelstahl

They are stabilized stainless steels featuring up to 0.6% niobium and tantalum. They are composed of between 17–19% chromium, 9–13% nickel, 2% manganese, and small amounts of carbon, phosphorus, silicon, and sulfur. Even at high temperatures, these stainless steels retain good mechanical properties and strength. You can weld them with common welding methods. You can use 347 stainless steel for heat exchangers, furnace components, tubing for oil refining and petrochemical industries, and exhaust manifolds.

Why Use Austenitic Stainless Steel?

The use of austenitic stainless steels for a specific application is due to their idealness in striking a balance between strength, corrosion resilience, processability, cosmetics, and cost. You can use other types of stainless steels when cost or cosmetics requirements are less important or where strength or component weight is more critical. Meanwhile, if you want stainless steels you can use for moderate high-temperature, cryogenic, or corrosion-risk applications, austenitic stainless steels are the perfect choice.

Applications of Austenitic Stainless Steel?

- Medizinische Ausrüstung: In the medical equipment sector, you can use austenitic stainless steels due to their ability to withstand constant sterilization cycles, aggressive disinfectants, and bodily fluids without surface degradation. They are compatible with human tissue, thus ensuring a minimized risk of contamination or implant rejection. Plus, they have long-term dimensional stability. You can use them for hip and knee implants, plates, screws, endoscopes, catheters, syringes, surgical tables, chairs, trays, cabinets, and medical carts.

- Energieerzeugung: The properties of austenitic stainless steels make them a perfect option for power generation and related applications. For instance, you can use 304 and 316 stainless steels for steam turbines and ancillary equipment. Meanwhile, 304, 316, and 321 alloys are perfect for boiler tubes, heat exchangers, and other areas where components are exposed to pressurized steam, thermal cycling, and oxidizing environments. You can also use them for condensers in power plants, gas turbines, exhaust systems, flue gas desulfurization (FGD) systems, and in water treatment plants.

- Architectural Structures: The beneficial properties of austenitic stainless steels mean you can use them for various architectural structures. Austenitic stainless steels are perfect for applications that require long-term outdoor exposure, minimal maintenance, and where surface appearance is critical. You can use them for indoor and outdoor applications like exterior cladding, handrails and balustrades, an architectural mesh of perforated sheet and expanded metal, and sculptures and art installations.

- Chemical Processing Equipment: In the chemical processing industry, austenitic stainless steels are perfect for managing acidic media, elevated temperatures, and continuous flow conditions. You can use molybdenum-bearing grades such as 316 and 904L for storage tanks, pressure vessels, pipes, heat exchangers, and other areas where localized corrosion could lead to leaks, contamination, or unplanned shutdowns, reducing maintenance frequency and extending service life.

- Kitchenware and Appliances: Austenitic stainless steel alloys are a great option for kitchenware and appliances, as well as other culinary applications. You can use 304 and 316 stainless steels for cutlery, kitchen sinks, refrigerators, dishwashers, ovens, cook pots, mixing bowls, and measuring cups due to their durability to tolerate frequent washing, food acids, thermal shocks, and mechanical wear without altering taste or surface integrity.

- Aerospace and Automotive Components: Austenitic stainless steels guarantee optimal performance in high-stress, high-temperature, and life-critical components in aircraft and spacecraft. For instance, you can use 304 and 321 grades in aircraft exhaust systems. You can use it for other applications such as components within hydraulic, pneumatic, and fuel systems, turbine blades, compressor discs, exhaust nozzles, bolts, nuts, coolant tubing, and valves, aircraft frames and structures, wing leading edges, flap actuators, and landing gear components.

Benefits of Austenitic Stainless Steel?

There are many benefits of austenitic stainless steels that make them irresistible in various industries. Some of these bemefits includes:

- Generally, these grades of alloys offer good to outstanding corrosion resistance.

- They maintain high strength at elevated temperatures, while some alloys display remarkable capability.

- They have highly attractive textured or polished surfaces, meaning they ensure durability through heavy use.

- Austenitic stainless steels are generally non-magnetic when annealed; however, are lightly magnetic when fully work-hardened. This makes them beneficial for chemical processing, medical, automotive, and food industries.

- You can use the hygienic surface of these alloys for all sectors.

- Austenitic stainless steels are ductile and malleable.

- Some low-carbon, high-nickel alloys are highly biocompatible.

Limitations of Austenitic Stainless Steel?

Despite the various benefits of austenitic stainless steels, their performance is limited in some types of applications.

- Austenitic stainless steels consist of expensive metals such as nickel, manganese, tantalum, and titanium, thus making them expensive.

- Although some types of alloys in austenitic stainless steels have good high-temperature performance, some competing materials outperform them in this regard.

- Some of these alloys face challenges of sensitization and weld sensitization.

- You cannot use them for some applications due to the inability to heat-treat them.

- It’s an extra burden for you to anneal them to minimize their magnetic sensitivity.

- They don’t work perfectly as bearing materials because they easily suffer from adhesive wear or galling.

Fazit

As you may know, many industries prefer austenitic stainless steel due to its corrosion resistance, strength, and versatility. When you choose the right type for your needs, you’ll get improved performance, extended service life, and reduced maintenance costs.

Häufig gestellte Fragen

How Long Does Austenitic Steel Last?

How long austenitic stainless stee last depends. Generally, austenitic stainless steels are durable materials that last a long time when you use the right grade for the right application.

Which Is Better Between Austenitic Stainless Steel And Stainless Steel?

Austenitic stainless steel is a type of stainless steel. It’s generally better for corrosion resistance, durability, and welding, while other stainless steels may be better or cheaper depending on the application.

Can Austenitic Stainless Steel Get Rusted?

Yes, austenitic stainless steels can rust, but they’re highly resistant due to a self-healing chromium oxide layer. Rust appears when this protective layer is damaged or overwhelmed by harsh conditions like chlorides (salt), strong acids, high heat, or surface contamination.

Is Austenitic Stainless Steel Magnetic?

No, austenitic stainless steels like 304 and 316 grades are generally non-magnetic in their annealed state because their crystal structure isn’t ferromagnetic. However, they can become slightly magnetic after cold working, bending, or welding, which creates some magnetic ferrite.

Entdecken Sie mehr mit unseren Blogbeiträgen.

kürzliche Posts

Erfahren Sie mehr über unsere Produkte

Kundenspezifische Produkte

Sofort kostenloses Angebot!