Komplette Fertigung kundenspezifischer Metallteile in China

Vereinfachen Sie Ihre Lieferkette mit integrierten Fertigungsprozessen, einschließlich CNC-Bearbeitung, Gießen, Schmieden und mehr.

🛡️ Alle hochgeladenen Inhalte werden sicher und vertraulich behandelt.

Kernkompetenzen

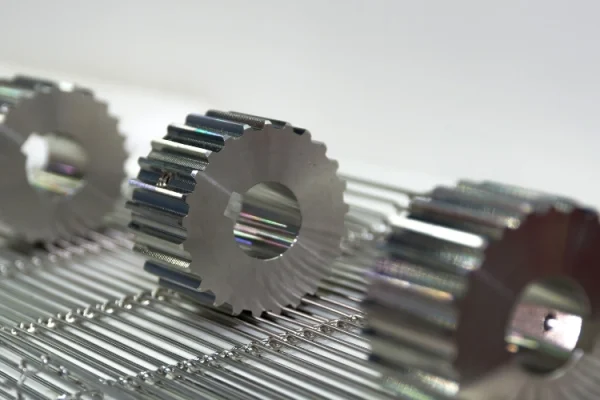

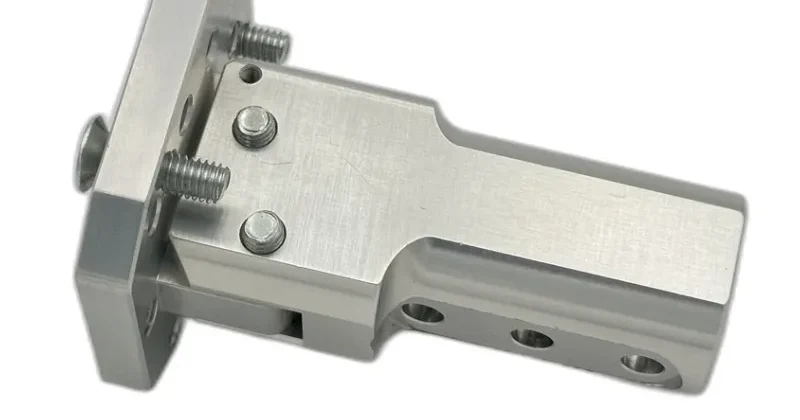

CNC-Bearbeitung

- Ausgestattet mit 3-Achsen, 4-Achsen, und 5-Achsen CNC-Bearbeitungszentren.

- Enge Toleranz bis zu ±0,005 mm.

- CNC-Bearbeitung kritischer Abmessungen für Guss- und Schmiedeteile.

- Kontrolle kritischer Abmessungen.

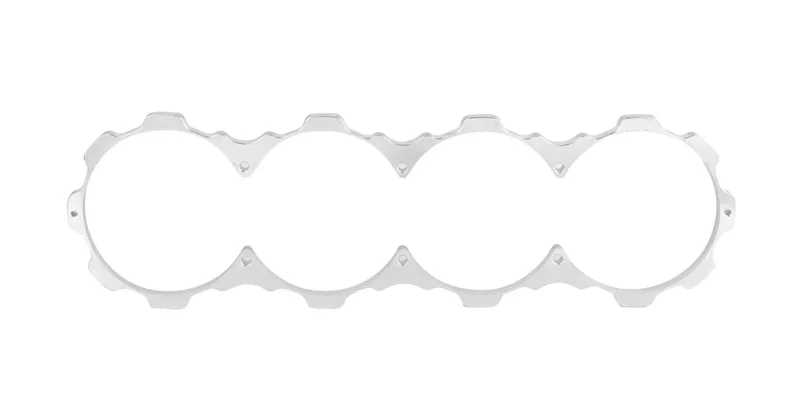

Casting

- Präzisionsguss mit rostfreier Stahl, Nickellegierung, und mehr.

- 50 kg maximale Einzelgussgröße.

- Enge Toleranzen bei CNC-Bearbeitung.

- Kundenspezifische Lösung in Gießverfahren, Materialkonfiguration, und Wärmebehandlung.

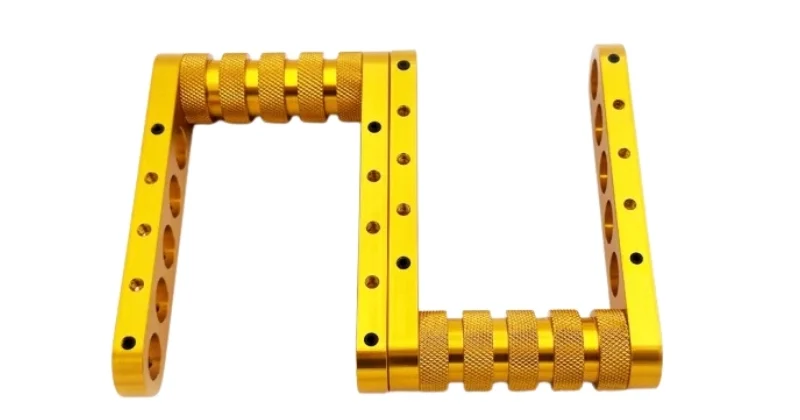

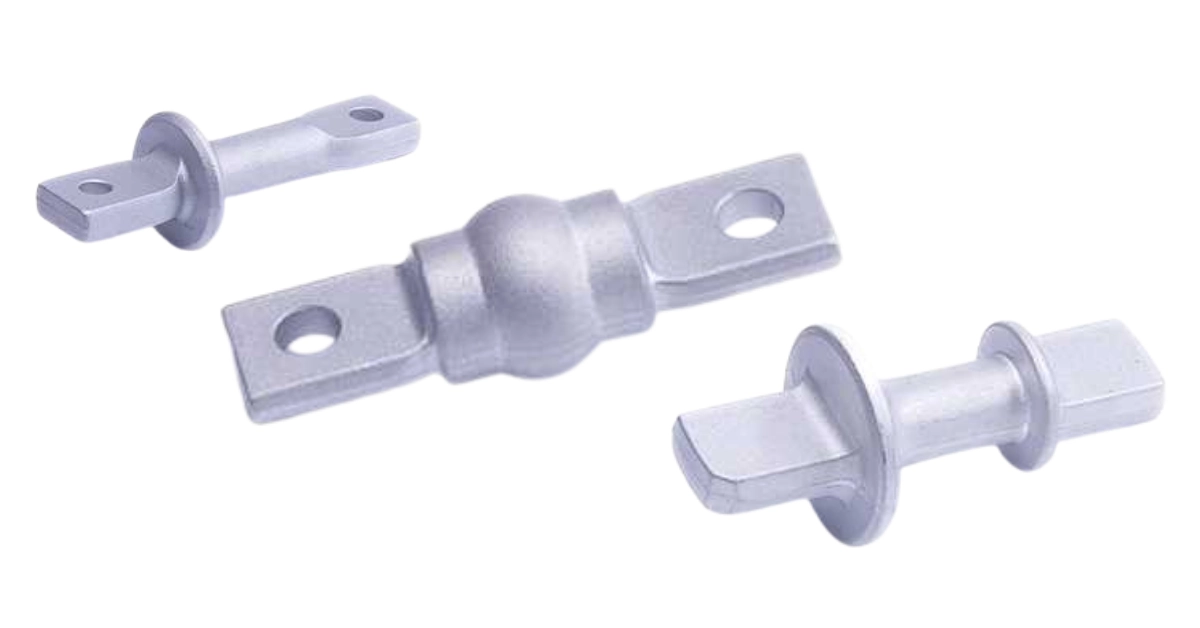

Schmieden

- Schmieden mit Aluminiumlegierung, Kohlenstoffstahl, und Edelstahl.

- 30 kg maximaler Einzelschmiedevorgang.

- 160T ~ 4000T Schmiedepressen und Schraubenpressen.

- Kalt- und Warmumformung sind möglich.

Weltweiter Service

Wir haben über 1000 Kunden aus mehr als 50 Ländern betreut.

ISO- und IATF-zertifiziert

Wir sind nach ISO9001:2005 zertifiziert.

Über 50 zertifizierte Materialien

Wir können Ihre Metallteile mit über 50 verschiedenen Materialien individuell gestalten.

Pünktliche Lieferung

Die Teile werden Ihnen wie versprochen zwischen 1 Woche und 30 Tagen geliefert.

Weitere Informationen finden Sie auf unserer Servicerichtlinie Seite.

Warum HDC Manufacturing wählen?

Mehr als nur ein Hersteller: Ihr Partner für Entwicklung und Lieferkette

Ein reales Projekt kann komplex sein und die Kombination mehrerer Fertigungsprozesse erfordern, um die gewünschten Komponenten herzustellen. Für Markenhersteller kann die Koordination mehrerer Lieferanten über verschiedene Prozesse hinweg schnell komplex und riskant werden.

Ausgehend von einer CNC-Werkstatt haben wir unsere Fertigungskompetenzen kontinuierlich ausgebaut und unsere Lieferkette weiterentwickelt, mit dem Ziel, unseren Kunden eine Komplettlösung anzubieten.

Mit unserer Kernkompetenz in der CNC-Bearbeitung vereinen wir Chinas führende Fertigungsressourcen im Guss- und Schmiedebereich unter einem einzigen, zuverlässigen Qualitätssystem. Von der Entwicklung und Beschaffung bis hin zur Qualitätskontrolle und Logistik übernehmen wir die Komplexität – damit Sie sich auf Ihr Produkt und nicht auf Ihre Lieferanten konzentrieren können.

Stärken Sie Ihre Marke mit maßgeschneiderten Lösungen

Bei HDC Manufacturing gehen wir über die reine Fertigung hinaus. Wir agieren als praxisorientierter Partner und unterstützen Sie bei der Umsetzung Ihrer Produktideen bis zur Serienreife. Von ersten Konzepten bis hin zu fertigen Bauteilen bieten wir kundenspezifische Metallteile und Präzisionsbearbeitung für aufstrebende und etablierte Marken gleichermaßen.

Mit integrierter CNC-Bearbeitung, Gießen und Schmieden helfen wir Ihnen, schneller voranzukommen, die Komplexität der Lieferkette zu reduzieren und eine gleichbleibende Qualität zu erreichen – damit Sie sich auf den Aufbau Ihrer Marke konzentrieren können und nicht auf die Verwaltung von Lieferanten.

Bestellvorgang

Erstberatung

Teilen Sie unserem Team Ihre Projektanforderungen mit. Wir prüfen Ihre Bewerbung und geben Ihnen praktische technische Hinweise, um Ihnen den Einstieg zu erleichtern.

Design-Einreichung

Senden Sie uns Ihre Konstruktionsdateien oder arbeiten Sie mit unseren Ingenieuren zusammen, um die Konstruktion im Hinblick auf Herstellbarkeit und Kosteneffizienz zu optimieren.

Angebot und Designprüfung

Sie erhalten ein klares, detailliertes Angebot sowie eine abschließende Überprüfung aller Spezifikationen, bevor es weitergeht.

Prototypenentwicklung

Bei Bedarf fertigen wir Prototypen an, um Design, Passform und Leistung vor der Massenproduktion zu überprüfen.

Produktion und Qualitätskontrolle

Nach der Genehmigung beginnt die Serienproduktion, die durch laufende Inspektionen und strenge Qualitätskontrollen in jeder Phase unterstützt wird.

Versand und Lieferung

Wählen Sie Ihre bevorzugte Versandart. Wir organisieren weltweiten Versand mit zuverlässigen Lieferzeiten.

Nutzen Sie unsere Ressourcen, um mehr über die Möglichkeiten von HDC zu erfahren.

Metallische Werkstoffe, mit denen wir arbeiten

HDC Manufacturing verarbeitet eine breite Palette von Metallwerkstoffen, um unterschiedlichen Anforderungen an Festigkeit, Gewicht und Leistung gerecht zu werden.

Umfassende Oberflächenbehandlungsoptionen

Mit integrierter hauseigener Oberflächenveredelung und einer zuverlässigen Lieferkette für die Nachbehandlung bietet HDC Manufacturing eine vollständige Palette von Oberflächenbehandlungen zur Verbesserung des Aussehens, der Haltbarkeit und der funktionellen Leistungsfähigkeit von kundenspezifischen Metallteilen.

| 🔷 Sandstrahlen | 🔷 Glasperlenstrahlen |

| 🔷 Anodisierung Typ II | 🔷 Anodisierung Typ III |

| 🔷 Pulverbeschichtung | 🔷 Malerei |

| 🔷 Verzinkung | 🔷 Verchromung |

| 🔷 Lasergravur | 🔷 Schwarzoxid |

Wärmebehandlung für Metallteile

Die Wärmebehandlung spielt eine entscheidende Rolle bei der Erzielung der erforderlichen Festigkeit, Härte und Haltbarkeit von Metallteilen.

Mit kontrollierten Wärmebehandlungsprozessen und einer zuverlässigen Lieferkette für die Nachbehandlung unterstützen wir ein umfassendes Spektrum an Wärmebehandlungsoptionen zur Optimierung der Materialeigenschaften für verschiedene Anwendungen.

| 🔷 Abschrecken | 🔷Härten |

| 🔷 Glühen | 🔷Normalisierung |

| 🔷 Lösungsbehandlung |

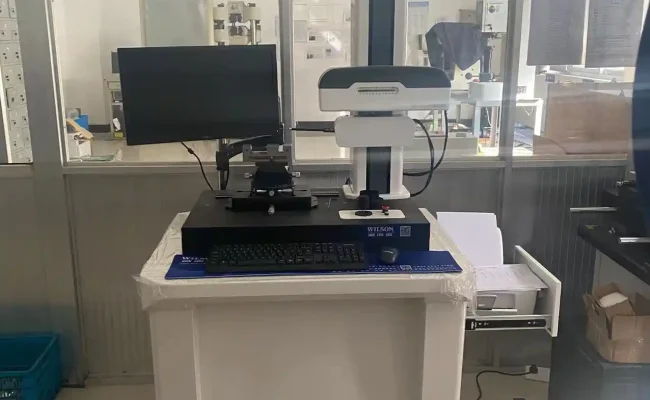

Qualitätskontrolle

Kundenspezifisch gefertigte Produkte

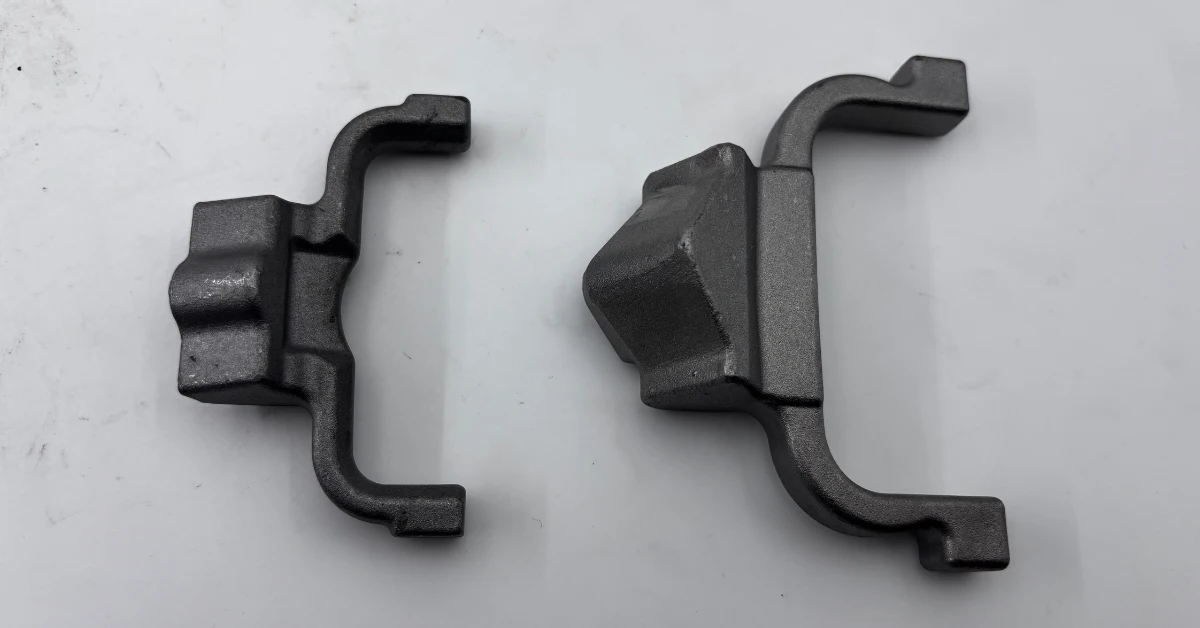

Geschmiedete, gegossene und CNC-gefräste Bauteile für diverse Branchen

Geschmiedete Automobilkomponenten

Geschmiedete Motorradkomponenten

Lenkrad- und Radzubehör

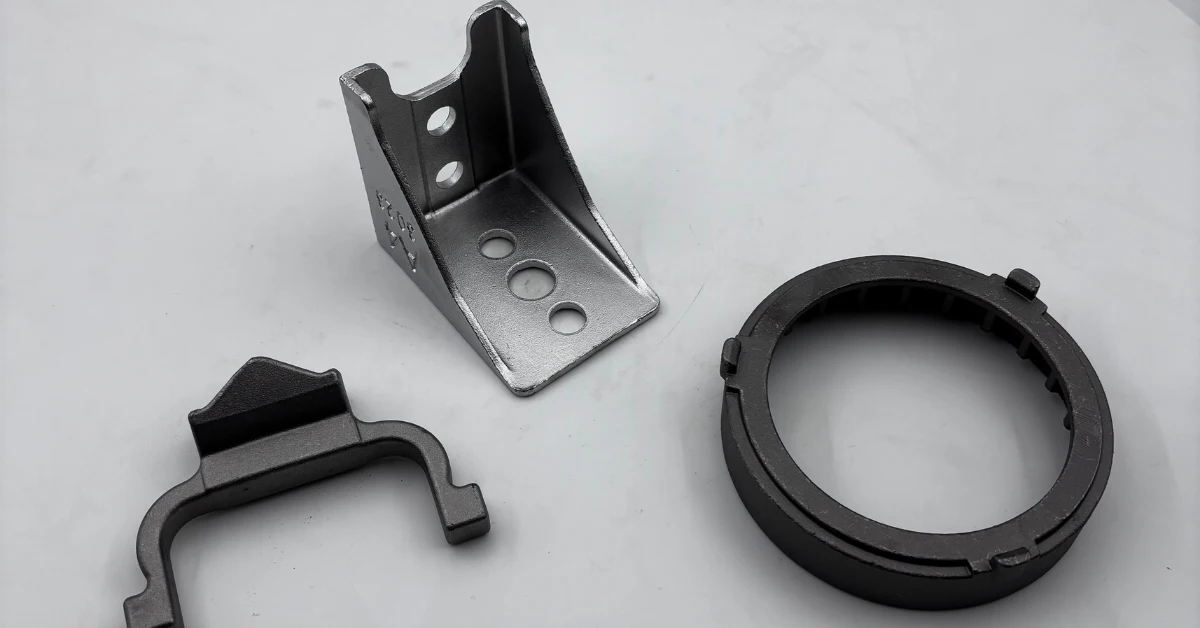

Geschmiedete Struktur- und Werkzeugkomponenten

Werkzeuge, Halterungen und Beschläge

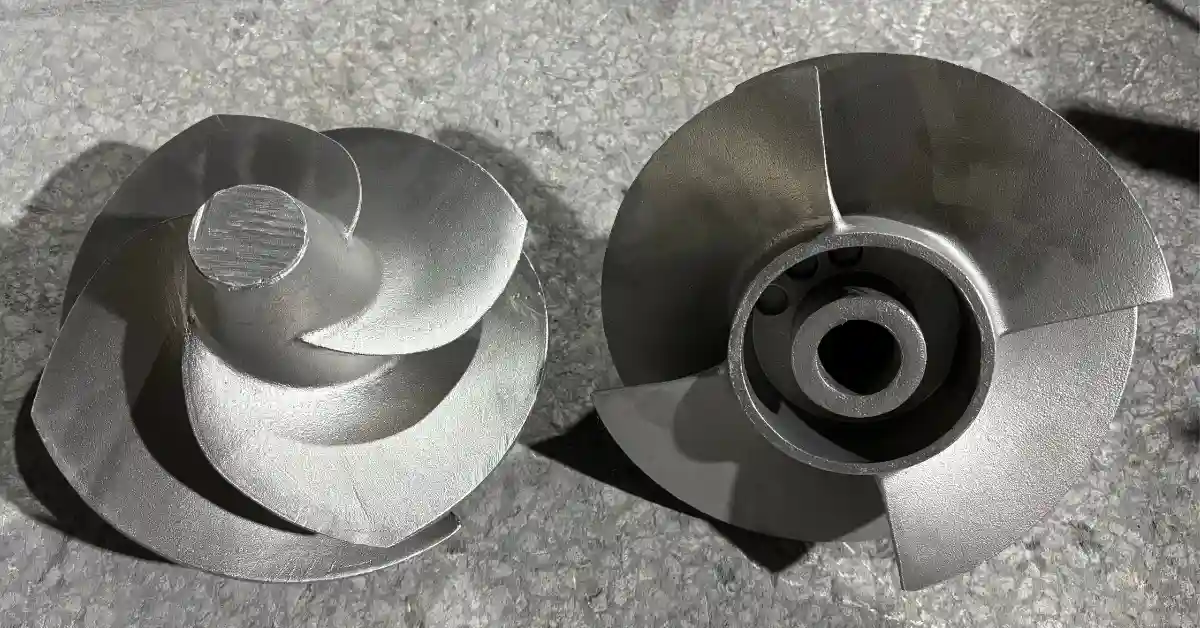

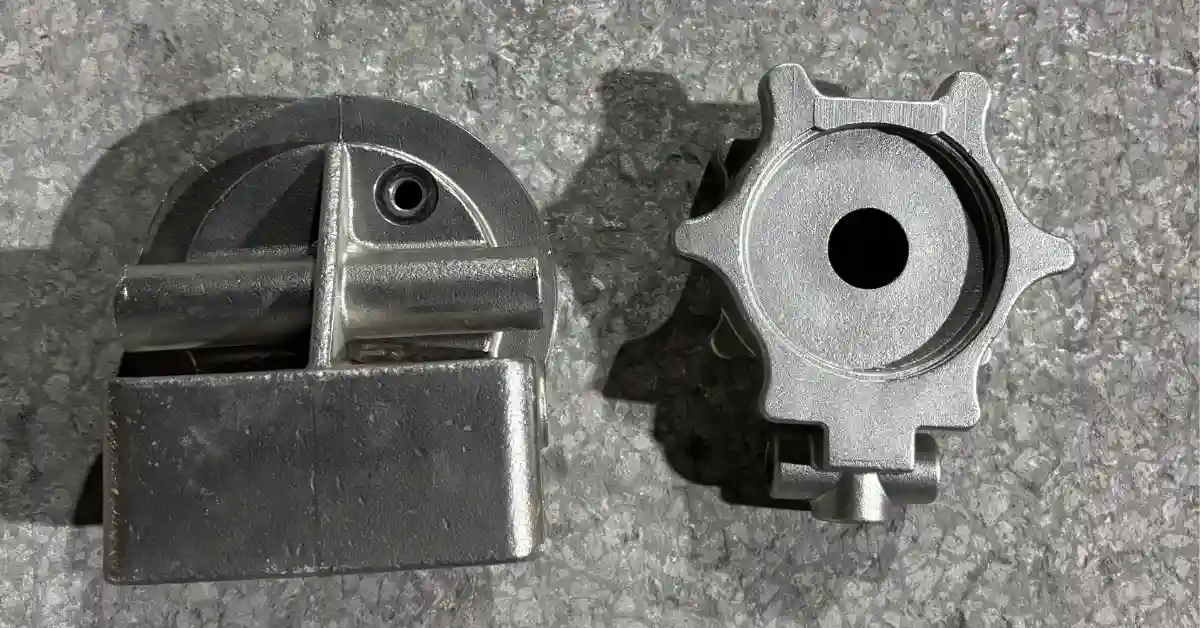

Industrielle Gussteile

Pumpengehäuse, Ventil, Getriebegehäuse

Fahrzeuggussteile

Auto-, Motorrad-, Fahrrad- und E-Bike-Teile

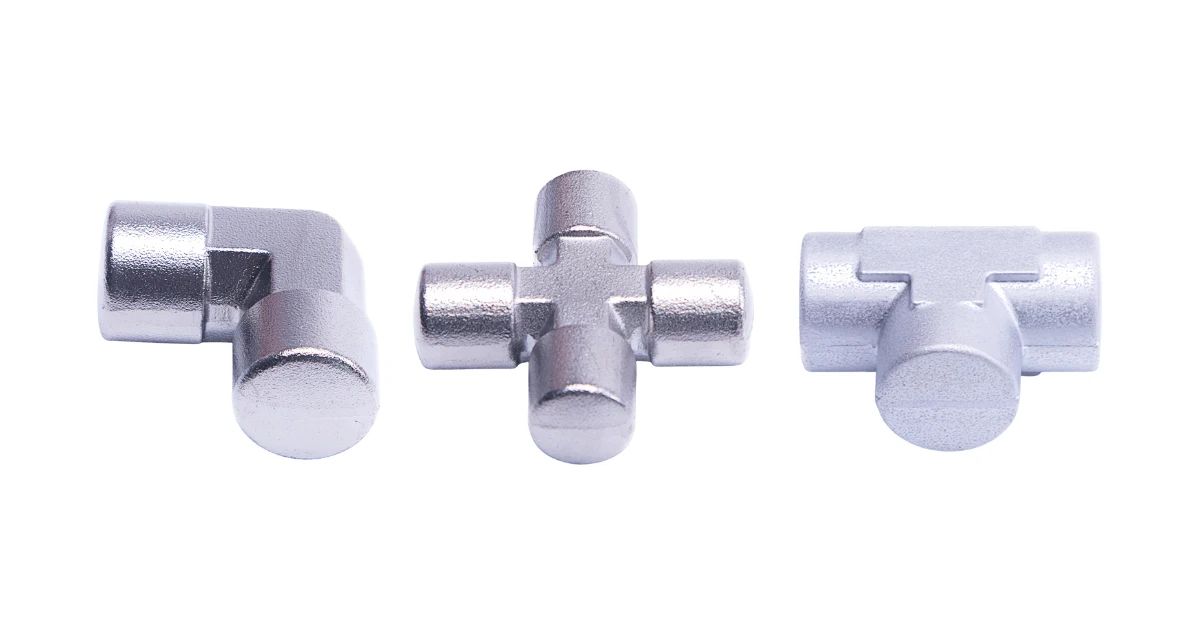

Hardware & Strukturgussteile

Steckverbinder, Halterungen und kundenspezifische Beschläge

Was unsere Kunden sagen

Häufig gestellte Fragen

Alles, was Sie wissen müssen, bevor Sie mit HDC Manufacturing zusammenarbeiten.

Wie fordere ich ein Angebot an?

Um ein Angebot anzufordern, teilen Sie uns einfach Ihre Projektdetails mit, inklusive Zeichnungen, Materialanforderungen und etwaiger Sonderspezifikationen. Unser Ingenieurteam prüft Ihre Angaben und erstellt Ihnen schnellstmöglich ein transparentes und detailliertes Angebot.

Wie lang ist die übliche Vorlaufzeit für Sonderanfertigungen?

Die Lieferzeiten variieren je nach Komplexität, Menge und Fertigungsprozess des Bauteils. Die meisten kundenspezifischen Projekte können innerhalb weniger Wochen abgeschlossen werden. Die voraussichtlichen Lieferzeiten werden im Rahmen der Angebotserstellung bestätigt.

Welche Versandoptionen stehen zur Verfügung?

Wir bieten flexible Versandoptionen an, darunter Luftfracht, Seefracht und Expressversand. Weltweiter Versand ist möglich, und FOB-Bedingungen können nach Ihren Wünschen vereinbart werden.

Wie stellt HDC Manufacturing die Produktqualität sicher?

Die Qualität wird in jeder Produktionsphase kontrolliert. Von der Rohmaterialprüfung über die Fertigungskontrolle bis hin zur Endkontrolle – unser Qualitätssystem ist ISO-zertifiziert, um Konsistenz und Zuverlässigkeit bei jedem Auftrag zu gewährleisten.

Gibt es eine Mindestbestellmenge (MOQ)?

Die Mindestbestellmenge (MOQ) hängt von Produkttyp, Material und Fertigungsprozess ab. Wir unterstützen flexible Produktionsvolumina und laden Sie ein, uns zu kontaktieren, um die optimale Lösung für Ihr Projekt zu besprechen.

Kann HDC Manufacturing bei Design oder Prototyping helfen?

Ja. Wir bieten technische Unterstützung und Prototyping-Dienstleistungen an, um Ihr Design hinsichtlich Herstellbarkeit, Leistung und Kosten vor der Massenproduktion zu optimieren.

Welche Zahlungsarten akzeptieren Sie?

Wir akzeptieren sichere Zahlungsmethoden wie Banküberweisung, PayPal und andere gängige Optionen. Die Zahlungsbedingungen werden während des Bestellvorgangs bestätigt, um Klarheit und Transparenz zu gewährleisten.

Bieten Sie Unterstützung für Erstimporteure?

Ja. Wir arbeiten regelmäßig mit Importeuren zusammen, die zum ersten Mal importieren, und bieten Beratung zu Incoterms, Zollabfertigung und Versandoptionen, um einen reibungslosen Importprozess zu gewährleisten.

Wie kann ich HDC Manufacturing kontaktieren, um weitere Informationen zu erhalten?

Sie erreichen uns über unser Kontaktformular, per E-Mail oder telefonisch. Unser Team freut sich darauf, Ihr Projekt mit Ihnen zu besprechen und Ihre Fragen zu beantworten.

Lassen Sie uns Ihr Design zum Leben erwecken

Laden Sie Ihre technischen Zeichnungen (STEP, IGES oder PDF) hoch, um innerhalb von 24 Stunden professionelles DFM-Feedback (Design for Manufacturing) und ein wettbewerbsfähiges Angebot zu erhalten.

* Technische Prüfung möglich. Eine Vertraulichkeitsvereinbarung kann auf Anfrage unterzeichnet werden.