OEM Forged Control Arm Manufacturer

Serving automobile manufacturers in China with high-strength forging components for years, HDC has rich experience in offering you high-quality forged control arms.

Control Arm by Application

We don’t just produce the control arm, we develop it. If your vehicle needs custom control arms, let HDC be your partner.

Automobile Control Arms

As a forging factory, about 45% of our forging parts are built for automotive, and among them, over 50% are kinds of control arms. You can trust HDC as a custom control arm provider just as the car factory in China.

ATV / UTV Control Arm

For an ATV or UTV, the control arm needs to combine high strength with a lightweight design to handle impacts and rough terrain. HDC provides 7075 alloy to forge these essential components.

Off-road Control Arm

Off-road car drivers know the importance of a reliable suspension system best. With HDC’s high-quality control arm forged from aerospace-grade aluminum, you can get the best off-road driving experience.

Kart Control Arm

Except for large vehicles, we also offer custom control arm service for small vehicles used for entertainment, such as go-karts, golf carts, and so on. We can manufacture according to your drawings or samples.

Control Arm by Type

HDC can fabricate and machine all kinds of control arms for you, OEM or custom designs, A-arms or L-arms.

Lower Front Control Arm

You can find a lower control arm in all three major suspension systems: MacPherson, double wishbone, and multi-link. It’s often made by forging high-strength aluminum, which is the area that HDC specializes in.

Upper Front Control Arm

The primary purpose of the upper control arms is to control the camber and caster angles of the wheel when the car is in motion. To achieve precise control, HDC fabricates it with close die forging and CNC finishing.

Lower Rear Control Arm

This control arm is positioned below the centerline of the rear wheel of a car, serving as a support point for the rear shaft and the shock absorber. By forging, we produce it with excellent strength to handle the heavy load.

Upper Rear Control Arm

The upper rear control arm is located above the centerline of the rear wheel. It collaborates with the lower arm to precisely control the camber angle changes of the rear wheels, bringing a better ride experience.

Toe Arm

The toe arm is usually a component of a multi-link suspension system in the rear wheel. It restrains the wheel, keeping it parallel to the car body, to keep the car stable when running straight.

Camber Link

As a part of the multi-link suspension system, the camber link helps to control the camber and avoid the wheel touching the ground unevenly. HDC applies CNC and forging to produce the camber link for precision and strength.

Trailing Arm

The trailing arm needs to bear the force produced by accelerating and breaking, keeping the wheel in its position. That’s why we’re forging it with high-strength aluminum to resist forward and backward stress and bending stress.

Adjustable Control Arm

The adjustable control arm often features a thread and a locking mechanism that allows the mechanics to adjust the length of the arm. With our CNC machining capability, we manufacture it with excellent precision

Warum HDC wählen

What makes HDC an excellent forging auto parts supplier in China? Here is the answer.

Expert Close Die Forging

Specialized in close die forging for over 10 years, HDC has rich experience in developing custom forgings from scratch.

Comprehensive CNC Machining

We forge and finish the control arm with our comprehensive in-house CNC machining capability, from 3-axis to 5-axis.

ISO- und IATF-zertifizierte Qualität

HDC is certified by ISO and IATF, following the strict quality control protocol to ensure the best quality of our forged control arm.

One-Stop Customization Solution

From DFM, mold manufacturing, to CNC finishing, surface treatment, HDC integrates the best resources to boost your project.

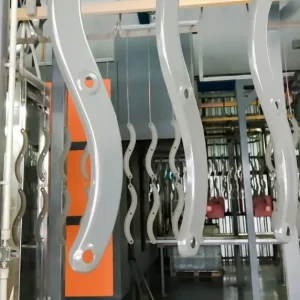

How HDC Forges Control Arm

How HDC turns billet into a high-quality control arm. Let’s break down.

Schmieden

At HDC, we utilize hot close die forging to manufacture control arms. Process with up to 4,000 T forging presses, we are able to forge control arms for vehicles from small to large.

Wärmebehandlung

After forging, we apply heat treatment based on the material and specification to refine the grain structure and enhance properties, including aging, tempering, etc.

CNC-Finishing

A precision mounting hole or thread is important for a control arm to operate well. We finish the key geometry and details with advanced CNC machines.

Schauen Sie sich unsere Qualitätskontrolle Verfahren zum Schmieden von Teilen.

Control Arm Materials

To maintain safety and the best performance of a suspension system, HDC offers the best quality materials you can find.

Aluminum alloy offers an excellent strength-to-weight ratio and is easy to form, making it an ideal material for forging control arms. According to the report published by WiseGuy, the aluminum control arm is gaining a significant market share in the automotive industry and is expected to continue growing.

HDC mainly offers 6061 and 7075 aluminum alloy for custom control arm projects.

Alloy steel control arms are robust and commonly used in heavy-duty vehicles, such as trucks and other commercial vehicles.

At HDC, we provide a wide range of alloy steel for forging control arms, including 20Cr, 20CrMo, 40Cr, and 42CrMo.

Control Arm Surface Treatments

HDC applies surface treatment for the control arm to produce a ready-to-use product.

We have an in-house automated pickling line, which allows us to strip the heavy oxide scale and contaminants from forged aluminum control arms with high consistency and quality.

Bead spraying eliminates fine tool marks and residual scale, giving the control arm a uniform, high-quality matte finish. Crucially, the process also creates beneficial compressive stresses on the surface of the component, which can effectively improve the fatigue resistance of the part.

Cooperating with reliable surface treatment factories, HDC can provide comprehensive coatings for your customization project, including epoxy coating, zinc coating, etc.

Technische Spezifikationen

Machen Sie sich ein umfassendes Bild von unseren Fertigungsmöglichkeiten, bevor Sie ein Angebot anfordern.

| Applicable Products | Upper Control Arm, Lower Control Arm, A-Arm, L-Arm, Trailing Arm |

| Manufacturing Method | Forging + CNC Machining |

| Supported Vehicle Types | Passenger Car, Pickup, SUV, ATV / UTV, Performance & Racing |

| Maximum Overall Length | ≤ 1200 mm |

| Maximum Width / Height | ≤ 600 mm |

| Maximum Single Part Weight | Aluminum ≤ 30 kg, Steel ≤ 5 kg |

| Maßtoleranz | ±0.05 mm(After machining) |

| Hole Position & Bore Accuracy | IT6–IT7 |

| Verfügbare Materialien | Aluminum Alloy (6061-T6, 6082, 7075-T6), Carbon Steel, Alloy Steel (4140 / 42CrMo) |

| Heat Treatment Capability | Aluminum alloy: T6 / T651 |

| Massenproduktionsfähigkeit | 300–10,000+ pcs / Month |

| Mindestbestellmenge | As low as 500 pcs (model dependent) |

| Quality Standard | ISO 9001 Manufacturing System |

| Customization Input | Drawing (2D/3D), Sample Reverse Engineering, OEM Reference |

Ready to launch your custom project?

Wenden Sie sich an HDC und erhalten Sie die kompetenteste Komplettlösung für Schmiedeprodukte. Senden Sie uns einfach eine E-Mail – unser Angebot ist kostenlos!

FAQ

What does a control arm do?

A control arm connects the vehicle chassis to the steering knuckle or wheel hub, allowing the suspension to move up and down while maintaining proper wheel alignment. It controls wheel position under braking, acceleration, and cornering loads.

What do the upper control arms do?

Upper control arms primarily manage camber and caster angles during suspension travel. They help keep the tire properly aligned with the road surface, especially during cornering and uneven terrain, improving steering stability and tire wear.

What does a lower control arm do?

The lower control arm supports most of the suspension load and resists vertical and longitudinal forces from the wheel. It works with the spring and damper to absorb impacts and transfer road forces safely to the chassis.

How many control arms are on a car?

Most vehicles use two control arms per wheel (upper and lower) in double-wishbone setups, or one lower control arm per wheel in MacPherson strut suspensions. Multi-link systems may use three to five arms per wheel, each handling specific loads.

What are the types of control arms?

Control arms can be classified by shape (A-arm, L-arm, straight arm), position (upper or lower), and application (passenger car, off-road, ATV/UTV, racing). The design depends on suspension geometry and load requirements.

What is the best material for control arms?

The best material depends on application. Forged carbon steel and alloy steel offer superior strength and fatigue resistance for heavy-duty and off-road use, while forged aluminum is often chosen for performance vehicles where weight reduction is critical.

How are control arms manufactured?

High-strength control arms are commonly produced by closed-die forging, followed by CNC machining for precision mounting interfaces. Forging aligns the metal grain flow with load paths, improving durability and fatigue life compared to casting or fabrication.

Is aluminum or steel better for control arms?

Steel control arms provide higher impact resistance and longer fatigue life under extreme loads, making them ideal for utility and off-road vehicles.

Aluminum control arms reduce unsprung weight and improve handling response but require precise forging and heat treatment to ensure strength.

What are the differences between control arms in different suspension systems?

Control arm design varies by suspension type. MacPherson strut systems typically use a single lower control arm, double-wishbone systems use both upper and lower arms for precise geometry control, and multi-link suspensions use multiple arms to independently manage wheel motion and load paths.

Verwandte Produkte