Custom Forged Flange Manufacturer in China

Specialized in forging, HDC promises to forge the best suitable flange for your piping system. You design it, we make it come true.

Types of Forged Flange

HDC manufactures most types of flanges on the market, and a customized model is also available.

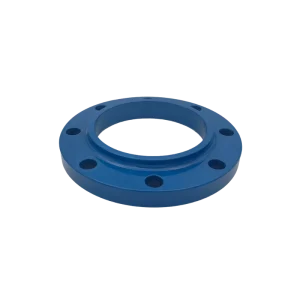

Aufsteckflansch

The slip-on flange is suitable for low to medium pressure pipe systems. You can easily slip it onto the pipe and weld it together. At HDC, we use CNC machining to precisely control tolerances and sealing surface finish, ensuring a perfect match and reducing leakage risk after welding.

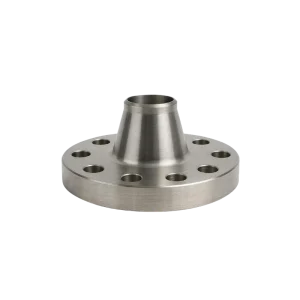

Vorschweißflansch

The weld neck flange has a tapered hub to butt weld with the pipe. This shape can transfer stress from the flange to the pipeline, forming a high-strength linkage, so it’s mainly used in high-pressure applications. By forging, we can produce it with high strength and low flaws to ensure safety.

Socket Weld Flange

You can plug the pipe into the socket of a socket flange, then install it by fillet welding. It’s preferred for small-bore and high-pressure piping systems. HDC combines forging and CNC finishing to ensure both the strength and precise geometry of the socket, making it a reliable component for your project.

Gewindeflansch

This type of flange has an internal thread and can be installed on a pipe with a matched external thread without welding. This means it’s suitable for low-pressure pipelines that need frequent disassembly and maintenance. With the multi-axis CNC machine, we can perform high-precision thread turning to ensure perfect engagement.

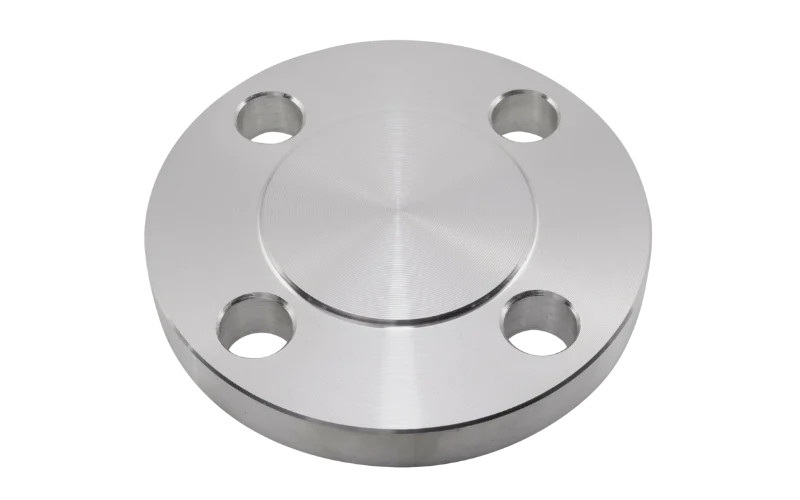

Blind Flange

Unlike other flanges, the blind flange is basically a solid disc without a central hole. It is used for sealing off a pipe, valve, or pressure container. Therefore, it needs to withstand high pressure. That’s why we use forging to fabricate the blind flange for an even, flawless, and dense grain structure to ensure rigidity under full load.

Lap Joint Flange

A lap joint flange comes with two parts: a flange and a stub end. During installation, the stub end is assembled with the flange and then inserted into the pipe. Then the stub end is welded to the pipe, leaving the flange free to rotate for convenient alignment of the bolt hole. We manufacture it with CNC to ensure smooth, unobstructed rotation.

Warum HDC wählen

What sets HDC apart from the hundreds of forging factories in China? Here is the answer.

Hochfestes Schmieden

Equipped with dozens of forging presses and screw presses, HDC is able to perform cold and hot close die forging to produce flanges with high strength and quality.

Präzisions-CNC-Bearbeitung

We forge and CNC finish flanges in-house with our comprehensive CNC machines, including 3, 4, and 5-axis CNC machining centers, with which we can achieve a tolerance of ±0.05mm.

Certified Materials

With over 20 grades of metal provided, HDC forged flanges that are best suited for your project. All our materials are purchased from reputable manufacturers and can offer certifications upon request.

One-Stop Forging Solution

HDC can provide a one-stop customization service from mold manufacturer to CNC finishing to build your flanges from scratch, backed by our comprehensive in-house manufacturer capabilities.

How HDC Fabricates Forged Flange

Learn how HDC fabricates custom-made flanges for industries around the world.

Schmieden

First, we forge the flange blank into a near-net shape using close-die forging, which is very close to the final product and requires minimal post-machining.

Wärmebehandlung

After forging, we introduce heat treatment processes according to the material, performance requirements, and applications to enhance the strength of a flange.

CNC-Finishing

In this step, we perform CNC turning, milling, and drilling using our multi-axis CNC center to finish the critical dimensions of a flange like the mounting surface, positioning hole, etc

Schauen Sie sich unsere Qualitätskontrolle Verfahren zum Schmieden von Teilen.

Verfügbare Materialien

All your material needs for a flange can be satisfied in HDC.

Carbon steel is a cost-effective material for flanges because it can be easily formed by forging and has a lower material price. Flanges made by it are primarily used in a pipe system that does not transfer corrosive media, such as water, air, oil, etc.

HDC offers a wide range of carbon steel for forging flanges, including Q355B, Q235, 20#, und 45#.

Alloy steel is a common material for flanges used in high-temperature steam, chemical process pipelines, and boilers. They have added certain elements to enhance properties, such as Chromium, Molybdenum, and Nickel, resulting in better strength and corrosion & heat resistance than carbon steel.

HDC forges flanges with a wide range of alloy steel, including 20Cr, 20CrMo, 40Cr, and 42CrMo.

Due to stainless steel’s excellent corrosion resistance and antibacterial properties, flanges made of it are favored in piping systems for industries such as chemicals, food processing, pharmaceuticals, seawater processing, and highly corrosive liquids.

Stainless steel is easy to form by forging. This is also what HDC specializes in; we can forge 304, 316L, 316Ti, und 2205 for your customized flange.

Super alloy flange can maintain high strength, corrosion resistance, and creep resistance under extreme conditions, and is an essential component in gas turbines, high-temperature heat exchangers, nuclear reactors, petrochemical, and marine engineering.

At HDC, you can get Inconel, Monel, und Stellit for custom flanges designed for harsh environments.

Available Surface Treatments

HDC forges and finishes the flange with comprehensive in-house capabilities.

This is an important surface treatment for flanges made of stainless steel, as it can form a thick oxide layer on a flange’s surface to enhance its corrosion resistance. This step is done in-house with our automated pickling equipment.

Polishing is often applied to flanges after forging or CNC machining to remove scale and tool marks. It can also improve the surface finish by bringing a mirror or stain finish for flanges made of stainless steel or super alloy. This treatment can also be done by our mechanical polishing and vibratory polishing.

Cooperating with reliable surface treatment factories, HDC can provide comprehensive coatings for your customization project, including epoxy coating, zinc coating, etc.

Technische Spezifikationen

Machen Sie sich ein umfassendes Bild von unseren Fertigungsmöglichkeiten, bevor Sie ein Angebot anfordern.

| Forging Capacity | 160T – 4000T pressing force |

| Gewichtsspanne | 0.01 kg – 30 kg per piece |

| Size Range | DN15 – DN1200 (1/2″ – 48″) |

| Bearbeitungstoleranz | ±0.05 mm (after machining) |

| Oberflächenveredlung | Ra 0.8 – 12.5 μm (as required) |

| Wärmebehandlung | Normalizing, quenching, tempering, annealing, stress relieving |

| Qualitätskontrolle | Analyse der chemischen Materialzusammensetzung Mechanical property testing Maßprüfung (KMG) Hardness testing Penetrant testing Ultrasonic testing (on request) |

| Facing Types | Flat face (FF), raised face (RF), ring type joint (RTJ) |

| Zertifizierung | Material certificates, dimensional reports per request |

| Produktionskapazität | 50,000+ pieces per month |

| Vorlaufzeit | 30-60 days (depending on quantity and complexity) |

Need Custom Flanges for Your Piping System?

Wenden Sie sich an HDC und erhalten Sie die kompetenteste Komplettlösung für Schmiedeprodukte. Senden Sie uns einfach eine E-Mail – unser Angebot ist kostenlos!

FAQ

What is a flange used for?

A flange is a mechanical connector that joins pipes, valves, pumps, or other equipment together. It allows easy assembly and disassembly of piping systems, while ensuring a tight seal to prevent leaks.

What are the different types of flange?

There are several common types of flanges, including Slip-On, Weld Neck, Socket Weld, Threaded, Blind, and Lap Joint. Each type has its own structure and application, from low-pressure pipelines to high-pressure, high-strength systems.

What is the most commonly used flange?

Slip-On and Weld Neck flanges are the most popular. Slip-On flanges are easy to install, while Weld Neck flanges are preferred for high-pressure applications because they transfer stress to the pipe for a stronger connection.

How to choose flange type?

It depends on your application. Consider the pipeline pressure, size, installation method, and whether you need to frequently disassemble the system. Slip-On is great for low to medium pressure, Weld Neck for high pressure, Blind for sealing, and Threaded for maintenance-friendly setups.

What are forged flanges?

Forged flanges are made by shaping metal under high pressure, creating a dense, strong grain structure. Compared to plate flanges, they have higher strength, better toughness, and lower risk of flaws. They are ideal for high-pressure or critical applications.

What is the difference between plate flange and forged flange?

Plate flanges are cut and machined from flat metal plates, while forged flanges are shaped under high pressure from solid metal. Forged flanges are stronger, more reliable under stress, and less prone to cracks or defects.

Does HDC provide prototypes for forged flanges?

Yes! HDC can produce prototypes before mass production, so you can check fit, dimensions, and quality before committing to a full order.

Verwandte Produkte