Sie suchen eine Metalllegierung, die selbst extremen Bedingungen standhält, in denen andere Metalle versagen? Dann ist Monel genau das Richtige für Sie! Diese Nickel-Kupfer-Legierung zeichnet sich durch hervorragende chemische, thermische und mechanische Eigenschaften aus. Lesen Sie weiter, um mehr über diese Superlegierung zu erfahren.

In diesem Leitfaden gehen wir detailliert auf Struktur, Zusammensetzung und gängige Sorten ein. Außerdem bieten wir eine eingehende Analyse seiner einzigartigen Eigenschaften. Bleiben Sie also dran!

Was ist eine Monel-Legierung?

“Monel ist eigentlich eine Nickel-Kupfer-Legierung, aus der man Teile herstellen kann, die in rauen Umgebungen eingesetzt werden müssen.”

Was die Zusammensetzung betrifft, so besteht Monel hauptsächlich aus einer Mischung von 65-70% Nickel, 20% Kupfer und 5% anderen Metallen wie Eisen, Mangan, Kohlenstoff oder Silizium. Diese Zusammensetzung macht das Metall so widerstandsfähig gegen Rost und Beschädigungen, insbesondere in maritimen Umgebungen.

Um eines klarzustellen: Es handelt sich nicht um eine Kupfernickellegierung, da Kupfernickel tatsächlich 60-70% Kupfer enthält. Monel hingegen enthält, wie bereits erwähnt, nur 20% Kupfer und unterscheidet sich daher grundlegend von Kupfernickel. Okay!

Eine kurze Geschichte

Nun ja! Wissen Sie, Monel wurde 1905 von Charles Elwood Wilson und Robert Crooks Stanley während ihrer Tätigkeit bei der International Nickel Company (INCO) entwickelt. Später, im Jahr 1906, erhielt es den Namen Monel, nach dem Präsidenten der INCO-Firma., Ambrosius Monell.

Seit seiner Entwicklung wurde es erstmals im Ersten Weltkrieg von den Vereinigten Staaten eingesetzt, wo es sich aufgrund seiner ausgezeichneten Korrosionsbeständigkeit und Festigkeit als wertvoll für Marine- und Militärausrüstung erwies.

Die Eigenschaften von Geldlegierungen verstehen

Chemische Eigenschaften

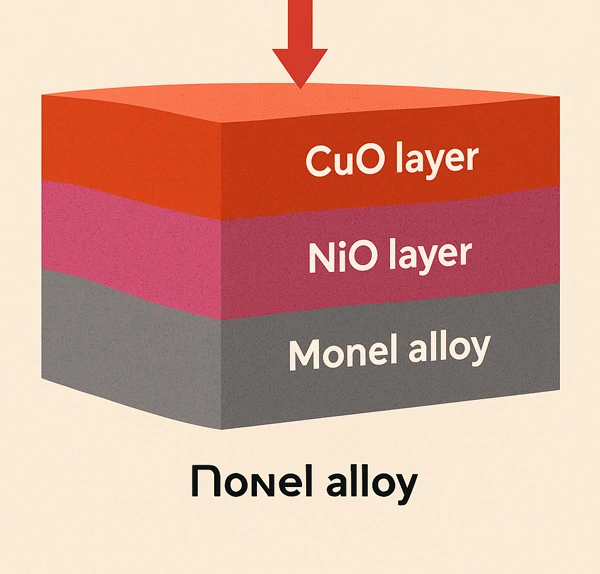

1. Korrosionsbeständigkeit: Eine der charakteristischen Eigenschaften von Monel ist seine hohe Korrosionsbeständigkeit. Dies liegt daran, dass es hauptsächlich aus Nickel oder Kupfer besteht, und beide Elemente sind von Natur aus chemisch stabil.

Daher bilden sie bei Kontakt mit Luft oder Sauerstoff, anstatt zu oxidieren, unlösliche NiO- oder CuO-Schutzschichten auf der Oberfläche. Dieser synergistische Effekt schützt das Monel somit vor Rost.

Darüber hinaus sind solche Oxidschichten passiv oder selbstheilend, was bedeutet, dass sie selbst bei geringfügiger Beschädigung durch oxidierende Säuren (wie Salpetersäure, Chromsäure, konzentrierte Schwefelsäure (H₂SO₄)) sofort weitere Oxide bilden und deren Angriff widerstehen.

| Chemische Art / Umgebung | Beispiel | Monels Widerstandsniveau |

| Oxidierende Säuren |

|

|

| Nicht-oxidierende Säuren |

|

|

| Schwache Säuren |

|

|

| Meerwasser / Salzwasser |

|

|

| Alkalien und Salze |

|

|

2. Nicht magnetisch: Darüber hinaus ist Kupfer von Natur aus stark nichtmagnetisch, was auch die magnetischen Eigenschaften von Nickel in der Monel-Legierung verringern kann. Daher können sie bedenkenlos in der Nähe empfindlicher Instrumente wie Sensoren, Kompasse usw. verwendet werden.

Thermische Eigenschaften

Monel ist zudem eine thermisch stabile Legierung; dies liegt an seinen hohen Schmelzpunkten von 1300–1350 °C. Daher besteht keine Gefahr der strukturellen Stabilität, da das Material auch bei hohen oder niedrigen Temperaturen nicht beschädigt wird.

Monel besitzt zudem eine moderate Wärmeleitfähigkeit, die niedriger als die von Kupfer, aber höher als die von Edelstahl ist. Daher eignet es sich gut für Wärmetauscher. Im Folgenden finden Sie eine kurze Übersicht seiner wärmetechnischen Eigenschaften.

| Schmelzpunkte | Siedepunkte | Wärmeleitfähigkeit | Der Wärmeausdehnungskoeffizient | Betriebstemperatur | Wärmekapazität | |

| thermische Eigenschaften von Monel | ~1300–1350 °C (variiert je nach Legierungssorte) | ~2730 °C | ~21–35 W/m·K | ~13–15 ×10⁻⁶ /°C | bis zu ~540 °C; | ~0,42 J/g·K |

Mechanische Eigenschaften

1. Zugfestigkeit: Nun ja! Zugfestigkeit ist die Fähigkeit eines Materials, unter Spannung stehenden Belastungen standzuhalten, bevor es bricht. Monel hat bekanntermaßen eine hohe Zugfestigkeit, da es … kubisch-flächenzentriertes (kfz) Kristallgitter. Aufgrund seiner Struktur kann es der Verformung somit tatsächlich widerstehen.

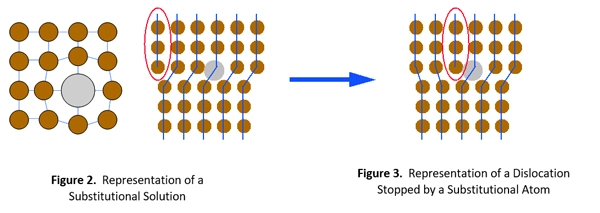

2. Streckgrenze: Es bezeichnet die Spannung, bei der sich Werkstoffe dauerhaft verformen. Okay! Im Fall von Monel ist diese Streckgrenze hoch, da die Legierung von Nickel mit Kupfer eine Mischkristallverfestigung bewirkt. Noch nicht verstanden? Ich erkläre es Ihnen! Zunächst einmal sind alle Kupferatome in einem Kristallgitter angeordnet und können Versetzungen (Fehlstellen) aufweisen. Wenn man das Metall zieht, bewegen sich diese Versetzungen und verbiegen das Metall leicht.

Fügt man hingegen Nickelatome hinzu, die etwas größer sind, so verzerren diese das Kupferkristallgitter. Dadurch wird die Bewegung der Versetzungen erschwert, was zu einer hohen Streckgrenze führt.

3. Härte: Die Nickel-Kupfer-Kombination in Monel verleiht dem Material zudem eine hohe Festigkeit und Widerstandsfähigkeit gegen Kratzer und Dellen. Durch Kaltverformung oder Wärmebehandlung wird die Festigkeit dieser Legierung weiter erhöht, da die Atome noch dichter gepackt werden.

| Zugfestigkeit | Streckgrenze | Härte | Duktilität | Härte | Ermüdungsresistenz | |

| die mechanischen Eigenschaften von Monel | 70.000–120.000 psi (480–830 MPa) | 30.000–70.000 psi (200–480 MPa) | 70–200 Brinell (HB) | 30–50 %-Verlängerung | Hoch | Exzellent |

Überblick über die Arten von Monel-Legierungen

Außerdem ist erwähnenswert, dass Monel in fast fünf gängigen Qualitäten vorkommt, die alle ihre einzigartigen Eigenschaften und Anwendungsgebiete haben. Werfen wir also einen kurzen Blick darauf!

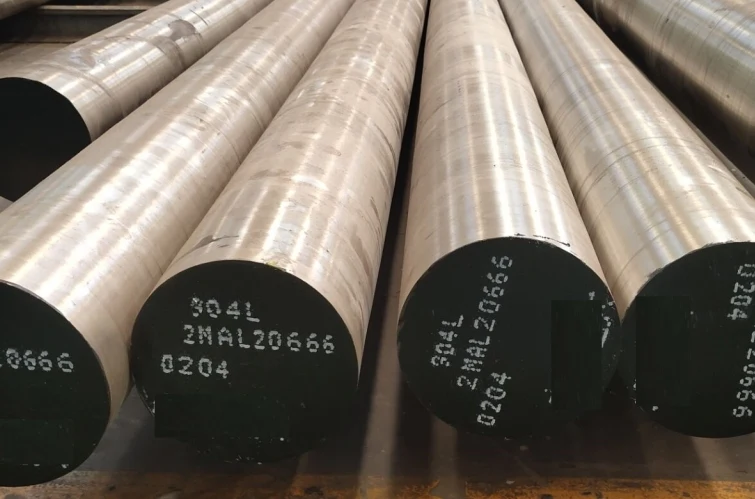

- Monel 400: Es handelt sich um die am häufigsten verwendete Monel-Legierung, die für ihre hervorragenden Korrosionsbeständigkeitseigenschaften bekannt ist. Daher eignet sie sich besonders für den Einsatz in der Chemie-, Öl- und Schifffahrtsindustrie.

- Monel 401: Monel 401 besitzt ähnliche Eigenschaften wie Monel 400, hat aber einen etwas geringeren Kohlenstoffgehalt. Dadurch ist die Wahrscheinlichkeit einer Reaktion von Nickel oder Kupfer mit Kohlenstoff unter Bildung von Carbid-Ausscheidungen bei hohen Temperaturen äußerst gering.

Aufgrund seines niedrigen elektrischen Widerstands (50–70 μΩ·cm, was bedeutet, dass der Strom leicht fließen kann) wird es häufig zu Streifen und Drähten verarbeitet.

- Monel 404: Im Vergleich zu anderen Monel-Sorten zeichnet sich dieses Material durch seine hohe Festigkeit auch bei extremen Temperaturen aus. Daher eignet es sich hervorragend für Spezialelektronik, da es sich auch gut zum Hartlöten (Verbinden von Metallen) eignet und eine geringe Permeabilität aufweist.

- Monel R-405: Hierbei bedeutet der Buchstabe R, dass es sich um eine spezielle Legierung für industrielle Anwendungen handelt, da sie eine hohe Korrosionsbeständigkeit und einen geringen Schwefelgehalt (~0,02–0,05%) aufweist, was ihre Bearbeitbarkeit im Vergleich zu anderen verbessert.

- Monel K-500: Bei Monel K-500 hingegen steht der Buchstabe K für ein spezielles Wärmebehandlungsverfahren, die sogenannte Ausscheidungshärtung. Dabei werden gezielt Elemente wie Aluminium (Al) und Titan (Ti) hinzugefügt, die sich im Inneren ausscheiden und so das Material härter und fester machen.

| Chemische Zusammensetzung | Korrosionsbeständigkeit | Härte | Elektrischer widerstand | Ideale Verwendungsmöglichkeiten | |

| Monel 400 | Ni 63–70, Cu 28–34, Fe ≤2, Mn ≤2, C ≤0,3, Si ≤0,5 | Exzellent | 70–200 | 50–70 | Marine-, Chemie- und Meerwasserausrüstung |

| Monel 401 | Ni 63–70, Cu 28–34, niedriges C, Fe ≤2, Mn ≤2, Si ≤0,5 | Exzellent | 70–200 | 50–70 | Elektroleisten, Drähte, Elektronik |

| Monel 404 | Ni 63–70, Cu 28–34, Fe ≤2, Mn ≤2, Si ≤0,5 | Gut | 100–220 | 55–75 | Strukturteile, Befestigungselemente |

| Monel R 405 | Ni 63–70, Cu 28–34, Fe ≤2, Mn ≤2, Si ≤0,5 | Exzellent | 150–250 | 55–75 | Pumpen, Ventile, chemische Verarbeitung, Luft- und Raumfahrt |

| Monel K 500 | Ni 63–70, Cu 28–34, Al 0,2–0,7, Ti 0,6–1,15, Fe ≤2, Mn ≤2, Si ≤0,5 | Exzellent | 180–300 | 50–70 | Schiffswellen, Pumpenwellen, Luft- und Raumfahrtkomponenten |

Wie kann man Monel verarbeiten?

Nachdem Sie nun die einzigartigen Eigenschaften von Monel kennengelernt haben, fragen Sie sich sicher, welche Verarbeitungstechniken es gibt. Keine Sorge, es gibt verschiedene Verfahren, mit denen Sie dieses wertvolle Metall in die gewünschte Form bringen können.

Man sollte jedoch bedenken, dass sie sich als Nickel-Kupfer-Legierungen anders verhalten als reine Metalle. Okay!

Heißarbeiten

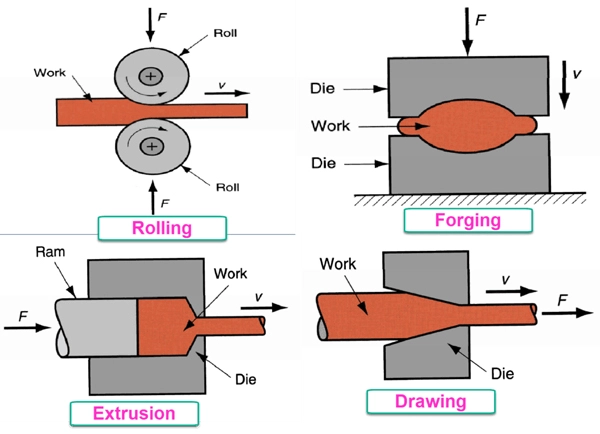

Bei dieser Technik wird das Metall üblicherweise durch Erhitzen über seine Rekristallisationstemperatur (ca. 900–1200 °C) geformt. Dafür gibt es verschiedene Methoden wie zum Beispiel… Schmieden (Hämmern/Pressen, um die gewünschte Form zu erhalten); Rollend (Zusammenpressen zwischen Walzen zur Herstellung von Blechen oder Streifen) oder Extrusion (Metall durch eine Matrize drücken, um lange Profile herzustellen).

- Anwendungen: Formbleche, Stäbe und Bauteile.

- Vorsicht: Beachten Sie, dass Sie Monel niemals in zu großen Mengen verzehren sollten, da dies zu folgenden Symptomen führen kann: Getreidewachstum, wodurch die Zähigkeit verringert wird.

Kaltbearbeitung

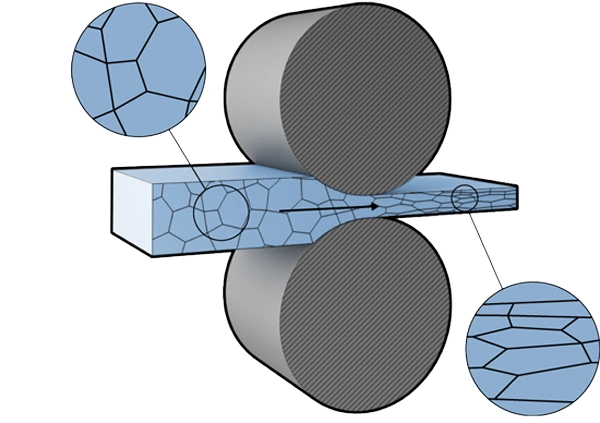

Um Monel noch härter zu machen, wird es kaltverformt. Dieser Vorgang wird als Kaltverfestigung bezeichnet. Die Verarbeitung erfolgt bei Raumtemperatur durch Walzen oder Biegen.

- Anwendungen: Drähte, Streifen und Kleinteile.

- Vorsicht: Sie sollten eine intensive Kaltverformung vermeiden, da diese die Bearbeitung erschweren kann.

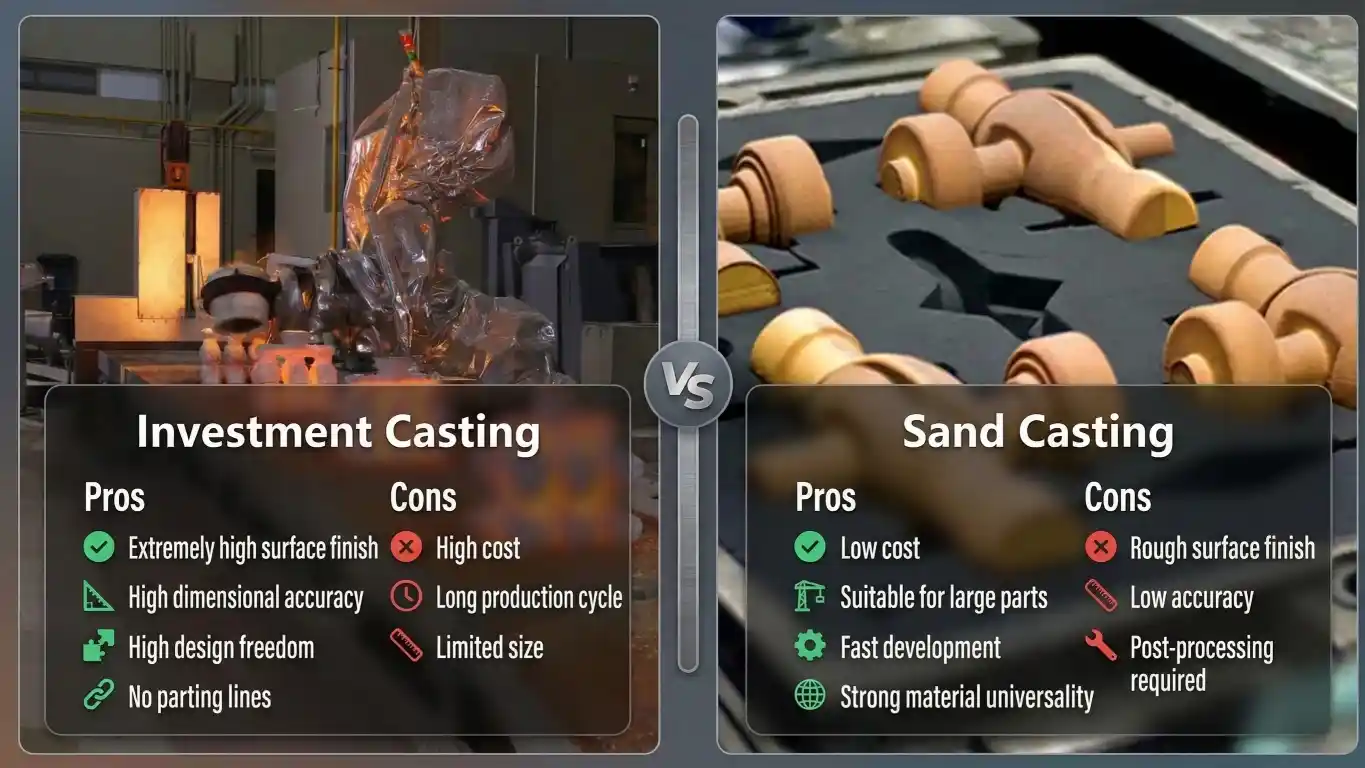

Casting

Darüber hinaus lassen sich Monel-Legierungen wie Monel 400 und Monel R-405 mittels Feinguss, Sandguss oder Druckguss in eine Vielzahl komplexer Formen bringen. Dies ist möglich, da die Legierung im geschmolzenen Zustand aufgrund ihrer Nickel-Kupfer-Zusammensetzung fließfähig wird und sich die Form dadurch gleichmäßig füllen lässt.

Zu Ihrer Information: Wir von HDC Manufacturing bieten kundenspezifische CNC-Bearbeitung, Fertigung und Gießen Dienstleistungen. Sie wissen ja, dass Monel einer unserer Gusswerkstoffe im Feingussverfahren ist.

- Vorsicht: Aber Achtung! Monel hat sehr hohe Schmelzpunkte (ca. 1300–1350 °C). Verwenden Sie daher unbedingt Hochtemperatur-Regelöfen, um Defekte zu vermeiden. Nach dem Gießen der Monel-Bauteile ist außerdem eine Wärmebehandlung (Glühen) erforderlich, um innere Spannungen abzubauen.

- Anwendungen: Befestigungselemente, Pumpen- und Ventilteile, Wellen

Schweißen

Monel kann auch durch Schweißen verbunden werden, wobei die Metallverbindungen durch Hitze, Druck oder beides hergestellt werden. Wichtig ist jedoch, dass die Hitze kontrolliert werden muss, da extrem hohe Temperaturen das Metall schwächen können. Deshalb wird Monel üblicherweise durch Schweißen verarbeitet.

- WIG-Schweißen (Wolfram-Inertgas)., das eine nicht verbrauchbare Wolframelektrode und Inertgas verwendet.

- Ein weiteres Beispiel ist MIG-Schweißen (Metall-Inertgas-Schweißen), wobei eine verbrauchbare Drahtelektrode und Inertgas verwendet werden.

Bearbeitbarkeit von Monel

Die Bearbeitbarkeit ist ein Begriff, der bei Metallen angibt, wie leicht oder schwer sie sich bearbeiten lassen. Wie Sie bereits erfahren haben, ist Monel eine sehr feste und zähe Metalllegierung und daher in der Regel schwer zu bearbeiten.

Herausforderungen: Wie bereits im vorherigen Abschnitt erwähnt, erhöht die Nickellegierung mit Kupfer die Härte von Monel zusätzlich, da sich Versetzungen im Gefüge verhaken und es dadurch noch härter wird. Beim Schneiden des Metalls entsteht daher, wenn man mehr Kraft aufwendet, als durch die Reibung zwischen Werkzeug und Metall entsteht, eine hohe Wärmemenge. Diese Hitze kann Sägeblätter verschleißen und deren Zähne beschädigen.

Doch damit nicht genug: Monel besitzt eine mäßige Wärmeleitfähigkeit; dadurch staut sich die Wärme an der Oberfläche, was die Kristallstruktur des Materials beeinträchtigen kann. Deshalb muss Monel langsam und mit geringen Vorschubgeschwindigkeiten bearbeitet werden.

Endgültiges Urteil

Aus der obigen Diskussion lässt sich schließen, dass Monel zwar teuer ist, aber außergewöhnliche Korrosionsbeständigkeit bietet, die von keinem anderen Metall erreicht wird. Darüber hinaus verfügt es über die bereits erwähnten hervorragenden thermischen und mechanischen Eigenschaften.

Aufgrund dieser Eigenschaften findet diese Metalllegierung breite Anwendung in verschiedenen Branchen wie der Schifffahrt, der chemischen und petrochemischen Industrie, der Luft- und Raumfahrt, der Öl- und Gasindustrie sowie der Elektro- und Elektronikindustrie. Um Monel-Gussprodukte zu erhalten, kontaktieren Sie uns bitte unter HDC Manufacturing.

Häufig gestellte Fragen

Ist Monel besser als Edelstahl?

Nun ja! Die Antwort hängt davon ab, wo Sie es einsetzen möchten. Monel ist zwar außergewöhnlich korrosionsbeständig und eignet sich daher besonders für chemische oder maritime Umgebungen. Für allgemeine Anwendungen können Sie jedoch Edelstahl verwenden, der ebenfalls korrosionsbeständig und im Vergleich zu Monel günstiger ist.

Warum ist Monel so teuer?

Monel ist eine sehr teure Legierung. Der Grund dafür liegt auf der Hand: Sie enthält einen hohen Anteil an Nickel (Nickel), einem sehr kostspieligen Metall. Hinzu kommt der komplexe Herstellungsprozess, der den Gesamtpreis von Monel zusätzlich erhöht. .

Ist Monel rostfrei?

Absolut ja, Monel ist aufgrund seiner Nickel-Kupfer-Zusammensetzung ein überlegenes rostbeständiges Metalldachmaterial, da es eine Oxidschicht bildet, die es selbst in Meerwasser oder sauren Umgebungen vor Korrosion schützt.