- Hogar

- Ressourcen

- Bloggen

- Arten von Gießverfahren

Types of Metal Casting: A Complete Guide to Foundry Methods and Their Applications

- Von: HDCMFG

Metal components are a crucial part of multiple applications. There are various ways these parts are manufactured, among which metal casting is a viable process. If you are looking to source high-quality metal parts made by metal casting, this guide is meant for you.

You will learn everything about the metal casting process and where it can be used. So, let’s read below.

Classification of Metal Casting Processes

Learning how casting processes are classified helps before moving on to specific techniques. Below is a detailed classification of metal casting processes.

Expendable Mold Casting

The mold used in expendable mold casting is discarded after each use. Casting your mold is like breaking the shell of an egg—the mold is removed as you pull out your casting. The system makes it easy to handle complex shapes and changes in design.

For example, there are sand, investment, and lost-foam casting. These methods are essential for making complicated shapes, where switching out molds is low-cost.

Non-Expendable (Permanent) Mold Casting

Thousands or hundreds of parts can be made from permanent mold casting’s reusable molds. Because the initial tools can create many copies, this approach is most helpful in producing products many times.

Examples are die casting, permanent mold casting, and centrifugal casting. Because they produce similar parts in batches, they maintain high quality, give attractive surfaces, and are cost-effective.

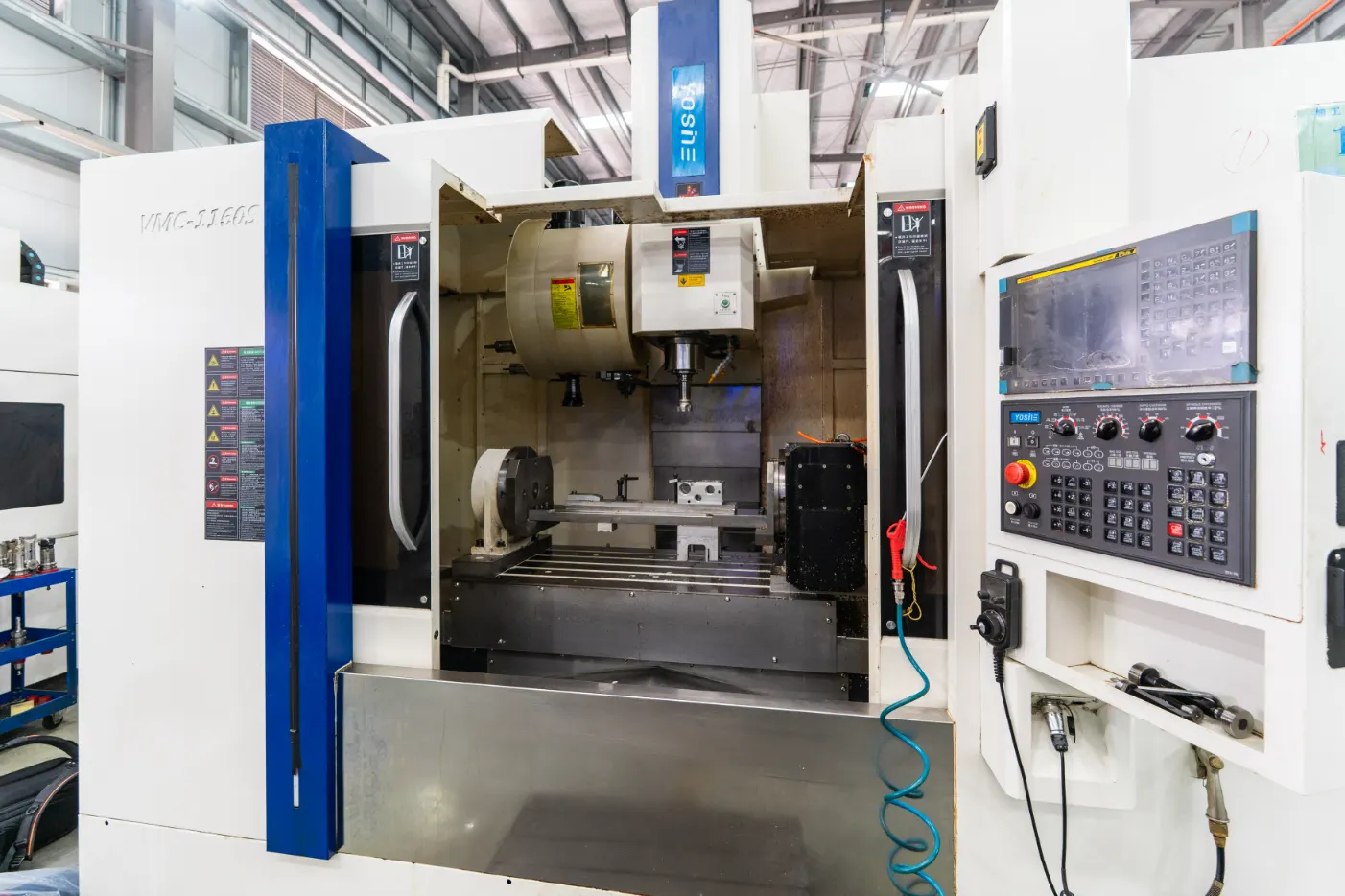

Detailed Overview of Metal Casting Types

We will now examine every casting process and discuss when and why you should use one over another.

Sandguss

Of all casting techniques, Sandguss is one of the oldest, and there are many good reasons it remains popular today. In this process, only special mold cavities are prepared in sand, followed by pouring molten metal into them. After the metal has hardened, you remove the sand to uncover what you’ve made.

Sand casting lasts so well because it can be used for various metals. Your metal foundry can cast both small ornaments and large industrial items. A sand mold can be made into any shape, so it’s perfect for producing complex forms that would cause trouble with other techniques.

Vorteile:

- Great for low-volume production since you don’t require costly molds

- Effective for parts that are too large for most other approaches

- Popular for fast and easy one-part projects

- It is compatible with casting nearly every type of metal

Nachteile:

- In most cases, a rough finish is machined again for a better look

- Compared to other methods, the results are less accurate in lower dimensions.

- It is tough to make if it is in an unusual shape.

Anwendungen: Engine blocks, pump housings, and artist sculptures use sand casting to achieve a smooth surface, which is less important than having a large object.

Investment Casting (Lost-Wax Casting)

First, a wax pattern is formed, and then refractory materials are applied in layers. After melting the wax, the metal fills the neat cavity it left behind.

The precision method achieves close tolerances as machined parts, yet it produces paths inside parts that cannot be machined.

Vorteile:

- No other method can offer the same accurate and easy sit-to-scale design.

- Excellent surface quality is achieved right from the mold.

- It can make relatively complex designs on the inside.

- Deals with many kinds of metals, including those used at extremely high temperatures

Nachteile:

- The process’s many different steps raise the expense.

- The fabric is produced with a longer process.

- We need to limit the size for practicality and financial reasons.

Anwendungen: These are used to build parts for airplanes, devices for humans, and designer rings where the surface is vital.

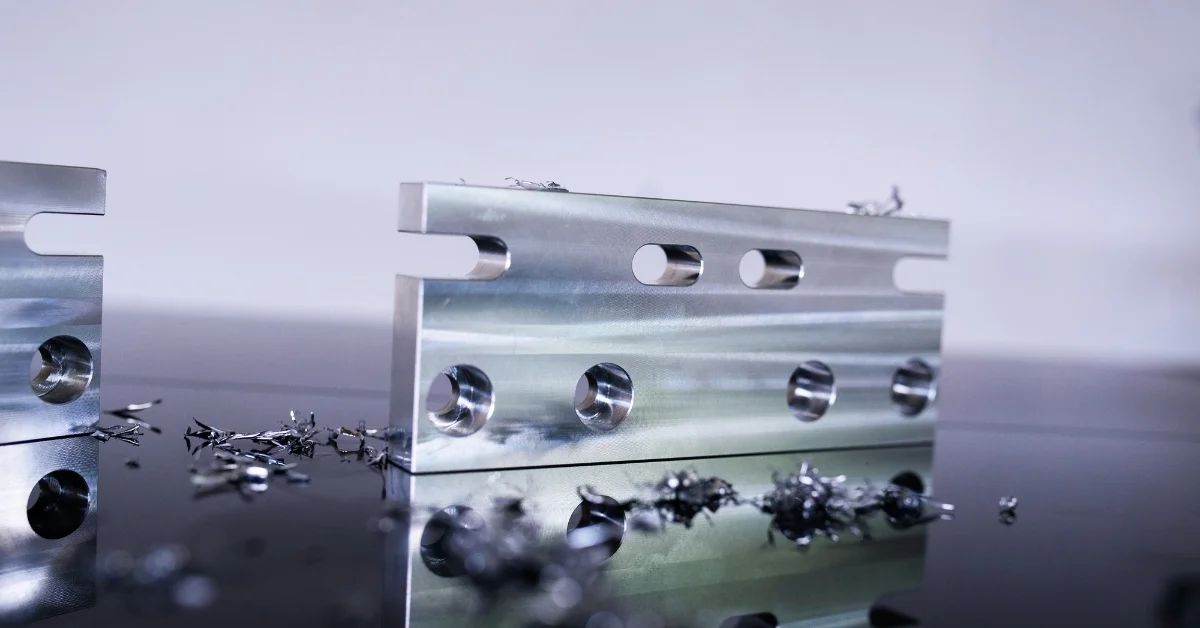

Druckguss

Under high pressure, hot metal is pushed into a metal mold and fills the cavity swiftly. This approach’s high temperature and pressure lead to parts with excellent dimensions and surfaces.

Vorteile:

- Very high production rates to fulfill tough manufacturing agendas

- Both the finish and the shape of the part are accurate

- Thin-walled components are so easy to produce with these molds.

- Don’t need much processing afterward.

Nachteile:

- You have to make a lot of parts to justify the high cost of the initial setup

- Only uses materials such as aluminum, zinc, and magnesium

- Restrictions on the design come from the need to cut parts out of rigid molds.

Anwendungen: Selected uses include housings for automotive gears, enclosures for electronics, and consumer goods sections.

Schleuderguss

Centrifugal casting uses rotation to shape metal into a cylinder, guided by centrifugal force to disperse molten metal and collect any impurities in the middle. As a result, castings are both thick and very strong.

Vorteile:

- Applications requiring superior mechanical properties are often cast to be very dense and fault-free.

- Pipes and tubes are perfect candidates for this type of machining.

- It is very suitable for areas where the strength must be combined with a low weight.

- Natural elimination of impurities

Nachteile:

- For the most part, only round or cylindrical symmetrical elements are allowed.

- The special spinning machines used by this industry add to its equipment costs.

- A reset is required when the load exceeds the equipment’s maximum capacity.

Anwendungen: Large-diameter pipes, flywheels, and liners inside cylinders benefit from the strong construction of centrifugal casting.

Dauerformguss

Permanent mold casting, which also works under gravity, is like sand casting because it’s reusable, but more like die casting since it requires more precision.

Vorteile:

- A glass surface finish that doesn’t require much extra work after the manufacturing process

- Each part is made to the exact dimensions as before.

- Made with faster production than sand casting

- For medium batch sizes, parts are cheaper to make.

Nachteile:

- It doesn’t work for models that have intricate structures on the inside

- It is more expensive to make a mold than for expendable mold methods

- Referred to mainly as metals with low melting points

Anwendungen: The surface of these materials is used for gear housings, automotive alternator housings, and plumbing fixtures.

Schalenformen

Das shell molding process leaves thin resin-sand shells on heated metal forms. Flame spraying achieves better results than sand casting and is more economical than investment casting.

Vorteile:

- Smooth skin that frequently allows us to skip machining steps

- Precise results on many levels

- It is suitable for things with many delicate parts.

- Considerably faster sand casting process than in the past

Nachteile:

- More money is needed for resin-made sand than for sand casting itself.

- Because of the handling process, parts can’t be too big.

- Making a pattern is more expensive than making a sand cast.

Anwendungen: Valve bodies, camshafts, and little gear components.

Plaster Mold Casting

Unlike sand, plaster mold casting uses plaster of Paris to give a smooth finish and excellent small details.

Vorteile:

- Because the surface finish is excellent, it rivals similar ones from machining.

- Perfect for details that must be fine

- Dimensions produced by this process are often better than those produced by sand casting.

- Perfect for design and decorations

Nachteile:

- Not recommended for metal items that must withstand high temperatures, such as steel

- Requires high skills compared to other casting processes.

- Using mold tools for just one batch adds to the price of every piece produced.

Anwendungen: Aluminum can be used for artistic statues, fittings, and handles that add value to your home, as well as precise metal parts.

Lost-Foam Casting

The main feature of lost foam casting is directly inserting foam patterns into molds. Heated metal evaporates the foam, replacing it and eliminating the need for intricate core systems inside the structure.

Vorteile:

- Cores are not required, not even in the most detailed parts of the design.

- Can make shapes that are more difficult to build than those made by other methods

- Excellent dimensions are achieved.

- Recognizing you don’t need as much machining.

Nachteile:

- It’s often hard to manipulate foam because it can be fragile.

- Vaporization issues mean van Arkel’s method only uses certain metals.

- Exceptional airflow is required to handle foam vapor removal.

- For complex patterns, fill costs can be surprisingly high.

Anwendungen: Lost-foam casting helps design engine blocks, pump housings, and architectural parts with difficult-to-form internal and external structures.

Squeeze Casting

Squeeze casting applies pressure to liquid metal within dies to make a solid metal product while combining the advantages of casting and forging. Porosity is eliminated, and the parts develop mechanical properties like wrought metals.

Vorteile:

- Strength and little porosity are achieved when pressure is applied.

- A valuable process for heat-treated alloys that improves with pressure forming

- High quality on both the finish and the dimensions

- The mechanical properties of this casting method are much better than those of conventional casting.

Nachteile:

- Equipping a hydraulic press for the job requires a lot of money.

- Bearings can be manufactured in only a few forms that will support pressure.

- Audited cast parts are finished in less time than the most extended cycle for traditional die casting.

- The design has to respond to the demand for pressure.

Anwendungen: Squeeze casting is applied to automotive wheel structures, aerospace structural components, and essential machinery components where reliability and strength are necessary.

Fortlaufendes Casting

With continuous casting, steelmakers no longer need to make ingots the old way. Liquid metal is formed into semi-products such as billets, blooms, and slabs, which are used immediately in rolling or other processes.

This technique allows for the continuous formation of solid metal, enhancing results and decreasing cost. In a controlled solidification environment, the casting achieves the same properties everywhere.

Vorteile:

- Excellent usage of resources, thanks to complete and uninterrupted operation

- A consistent size, style, and feel all the way along

- You won’t need to cast or roll ingots into smaller coils anymore.

- It is ideal for making lots of the same kind of shape.

Nachteile:

- You need to pay a high fee to get the specialized equipment.

- They are only possible based on a range of simple cross-sections

- A good metalworking craft requires metal chemistry and temperature to be maintained.

- Most of their uses are with ferrous metals and aluminum.

Anwendungen: Steel slabs are used in making plates and sheets, aluminum billets are critical for extrusion processes, and copper rods are needed for wire drawing—all thanks to the reliable speed and appearance of the steel created by continuous casting.

Low-Pressure Die Casting (LPDC)

When die casting is done at low pressure, the molten metal is moved into the mold cavity from its bottom using 0.5-1.5 bar of pressure. This soft pressure fullness permits solidification with calibrated temperature, resulting in fewer flaws and better properties of the part.

As the metal rises and pressure is controlled, the equipment helps produce castings with excellent mechanical capabilities. Therefore, LPDC finds special applications in systems that require maximum safety.

Vorteile:

- Makes castings with only a little porosity and good quality

- Perfect for architects dealing with complex shapes and thin walls

- Improved mechanical properties are the result of controlled solidification.

- Very well suited to applications that require safety.

Nachteile:

- Slow production is a disadvantage compared to what is achieved in high-pressure die-casting

- Gravity casting processes have lower tooling costs than die casting

- Unsuitable for significant parts because of the high pressure needed

Anwendungen: LPDC’s structured solidification method is used in automotive wheel safety, solid engine parts, and aerospace parts that need reliability.

Vakuumguss

Vacuum casting almost entirely eliminates air entrapment and gas porosity, drawing molten metal into the mold cavity. Excellent quality and finish make this structure appropriate for essential applications.

Vacuum conditions enable the mold to be filled even in thin parts, preventing gas-caused defects that might reduce the part’s integrity. This fact gives vacuum casting its advantage when high performance is needed.

Vorteile:

- Castings that have a great exterior appearance

- Lower rate of small pores and gas being trapped

- It fits the requirements of thin-walled products and different mechanical parts

- Perfect for uses that count on making casting error-free parts

Nachteile:

- Increased costs for things used on the job and for running the business

- Some materials and part sizes can’t be worked with a lathe

- Slower work because of the vacuum system requirements

- What specialized equipment is needed for maintenance

Anwendungen: Vacuum casting creates aircraft parts that can’t fail, healthcare items designed for the body, and parts that call for tight tolerances. It offers excellent quality benefits.

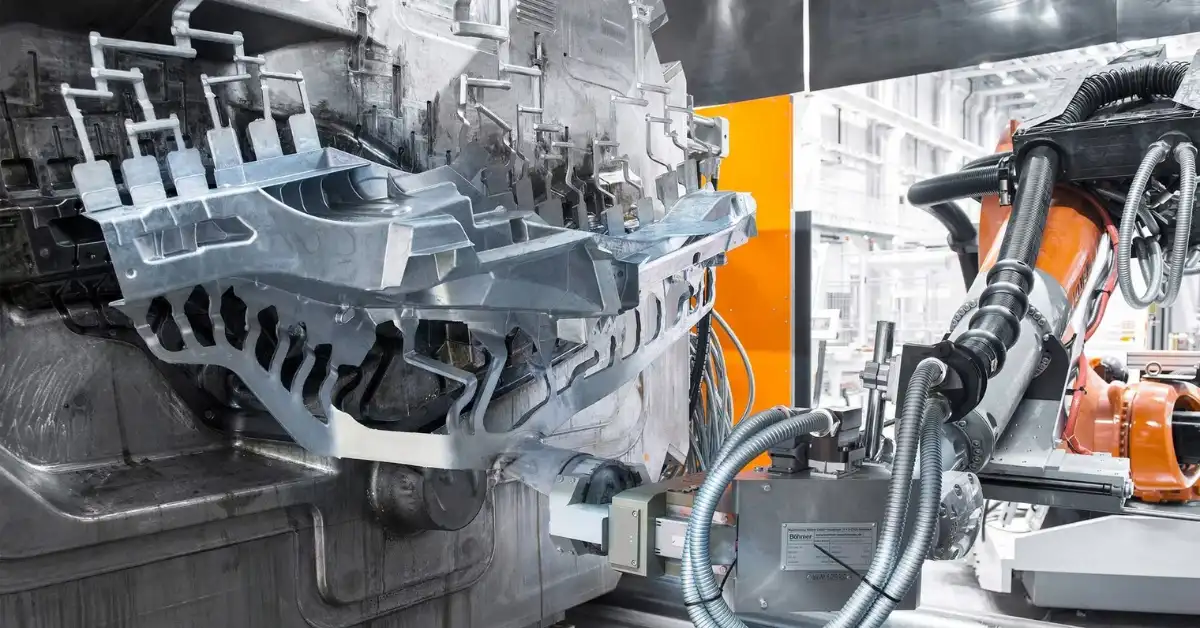

High-Pressure Die Casting (HPDC)

Die casting is known for putting molten metal into steel molds at pressures ranging from 1500 to 25,000 psi. As a result, products are filled quickly, finished well, and can be made in large numbers as thin, intricate parts.

This process allows parts to have premium size and surface standards, which means many secondary steps are often eliminated. As a result, HPDC is perfect for producing many precise components.

Vorteile:

- Furthermore, precision machining machines provide high numbers of parts each hour and amazing accuracy in shape.

- An even finish means you can spend less time doing extra work afterward.

- Perfect for small and complex parts whose walls are fragile

- Great for when large products are needed

Nachteile:

- A considerable start-up cost for the tools and equipment

- Unmanaged pores can be a problem.

- I only worked with non-ferrous metals

- That makes design more complicated and raises the associated costs.

Anwendungen: HPDC offers quick and accurate results for transmission housings for cars, small objects in consumer products, and parts of industrial machines that require many units every day.

Schwerkraft-Druckguss

With gravity die casting, metal is poured into molds using gravity to shape it. This procedural method produces products with higher quality and surface texture than sand casting without the complexity or high prices of pressure-assisted methods.

The process ensures medium-volume production is both high-quality and cost-efficient. Both methods are designed to decrease costs, provided the items are done similarly.

Vorteile:

- An item’s measurement matches the design and the smoothness of its surfaces

- You will find slower cooling with air-molded products than with sand casting.

- It goes well with production in medium to high quantities

- Equipment prices are usually lower for equipment than for pressure.

Nachteile:

- It is more costly to use tooling in permanent casting than in sand casting

- The design allows for basic geometries only because gravity feeds the food.

- These systems transfer hydrocarbons more slowly than pressure-assisted methods.

- Mold life lasts only so long before it wears out.

Anwendungen: Gravity die casting gives automotive elements such as brakes, plumbing, and cookware that require a good finish, a cost-effective choice for high standards.

Fazit

Many metal casting options are designed to address specific manufacturing challenges. You will achieve success by matching the process to your business needs.

Want to boost your manufacturing with accurate metal casting? HDC Manufacturing brings together many years of experience and the latest technology to ensure we deliver outstanding results.

We help you determine the best casting method for your projects so they are effective, efficient, and save money. Kontaktiere uns immediately to see how our broad expertise can make your designs real and accurate.

Entdecken Sie mehr mit unseren Blogbeiträgen.

kürzliche Posts

Erfahren Sie mehr über unsere Produkte.

Verwandte Produkte

Sofortiges Angebot!